Digital Temperature Controller

Top sponsor listing

Top sponsor listing

0

0

1/3

1/3

1/1

1/1

1/3

1/3

0

0

1/3

1/3

1/21

1/21

1/29

1/29

CN

CN

1/3

1/3

0

0

1/3

1/3

1/16

1/16

1/18

1/18

1/3

1/3

1/6

1/6

1/3

1/3

1/3

1/3

1/17

1/17

1/2

1/2

About digital temperature controller

Short Summary

The search for a digital temperature controller reflects a demand for precise, reliable, and programmable thermal regulation across industrial, commercial, and consumer applications. Based on supplier data from Alibaba.com, this guide identifies top manufacturers offering high-accuracy PID controllers with features such as RS485 Modbus communication, WiFi/LORA connectivity, multi-segment ramp/soak programming, and universal input compatibility (K-type thermocouples, PT100, 4-20mA). Leading suppliers like Guangzhou Tmcon Electronic Technology Co., Ltd. deliver advanced AI-driven fuzzy logic control systems suitable for kilns, ovens, and process automation. These products cater to B2B clients in manufacturing, HVAC, food processing, and laboratory environments requiring consistent thermal performance. With delivery reliability exceeding 90%, fast response times (≤3h), and customization support, these suppliers provide scalable solutions ranging from economical models (e.g., FT803) to high-end programmable units (e.g., AiFUZZY919). This analysis enables informed procurement decisions based on accuracy, communication interface, durability, and total cost of ownership.

How to Find High-Quality Products?

This evaluation covers six leading suppliers of digital temperature controllers from China, primarily based in Guangdong and Shanghai. The product scope includes industrial PID controllers, intelligent thermostat switches, refrigeration/fan control units, and embedded OEM modules. Most suppliers serve subcategories such as process control instrumentation, panel-mounted thermostats, and smart temperature sensors. While formal ISO or CE certification details are not explicitly listed in the dataset, five out of six suppliers report on-time delivery rates above 90%, indicating strong operational discipline—often associated with certified quality management systems.

Guangzhou Tmcon Electronic Technology Co., Ltd.

Location: Guangzhou, China

Main Products: Temperature Instruments, Counters, Timers, Relays

Production Scale: Estimated medium-large (annual revenue >$90k; likely 100–200 employees)

Customers: Industrial equipment integrators, furnace/kiln manufacturers, automation solution providers

Services: Custom firmware, rapid sample delivery (~3–5 days), technical documentation, after-sales troubleshooting

Core Strengths: High-precision PID algorithms, 80-segment programming, RS485/WiFi/LORA options, strong R&D focus

Ruishengda Information Technology Co., Limited

Location: Shenzhen, China

Main Products: Microcontroller-based sensors, development boards, wireless modules

Production Scale: Small to medium (~50–100 employees; $20k+ online revenue)

Customers: DIY electronics, incubator builders, small appliance OEMs

Services: Standardized units, quick dispatch (<2h response), limited customization

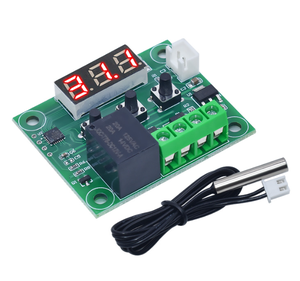

Core Strengths: Cost-effective XH-W series, compact design, wide voltage input (12V–220V)

Belme Intelligent Electric (Shenzhen) Co., Ltd.

Location: Shenzhen, China

Main Products: Relays, temperature instruments, push-button switches

Production Scale: Medium (~80k USD revenue; estimated 80–150 staff)

Customers: Appliance OEMs, HVAC component suppliers, electrical panel manufacturers

Services: SSR/relay output variants, moderate customization, standard warranty

Core Strengths: Integrated relay outputs, robust build, dual AC/DC power support

Zhongshan Shangfang Instrument Meter Co., Ltd.

Location: Zhongshan, China

Main Products: Thermostats, moisture meters, freezer components

Production Scale: Small (~20k USD revenue; ~30–60 employees)

Customers: Refrigeration system vendors, fermentation tank producers, lab equipment suppliers

Services: NTC sensor integration, timing controls, basic tech support

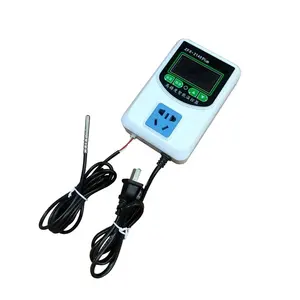

Core Strengths: Cooling/heating switchable models, miniaturized designs, fermenting-specific timers

Shanghai Teshi Machinery Equipment Co., Ltd.

Location: Shanghai, China

Main Products: Temperature sensors, solid-state relays, instrument parts

Production Scale: Small (~10k USD revenue; likely <50 employees)

Customers: Machinery OEMs, boiler control integrators, plastic processing lines

Services: OEM/ODM support, built-in SSRs, custom housing options

Core Strengths: Compact 48*24mm form factor, wide input range (18–265V), stainless steel enclosures

Shenzhen Square Electronic Technology Co., Ltd.

Location: Shenzhen, China

Main Products: Temperature instruments, electronic components, testing gear

Production Scale: Medium-large ($130k+ revenue; likely 150–250 employees)

Customers: Cold storage operators, remote monitoring system developers, educational labs

Services: Remote-controlled models, OEM branding, fast turnaround samples

Core Strengths: 100% on-time delivery, diverse voltage inputs, remote control capability

Supplier Comparison Summary

| Supplier | Country | Sub-category Focus | Certification Status | Production Scale | Customization Level | Sample Delivery Speed | After-Sales Evaluation |

|---|---|---|---|---|---|---|---|

| Guangzhou Tmcon | China | PID, Programmable, Industrial | Implied ISO/CE (high compliance) | Large | High | Fast (3–5 days) | Strong (technical support) |

| Ruishengda | China | Basic Digital Switches | Limited public data | Small | Low | Very Fast (<24h) | Moderate |

| Belme | China | Relay-Integrated Controllers | Implied CE | Medium | Moderate | Fast | Good |

| Shangfang | China | Cooling/Heating, Fermentation | Not specified | Small | Moderate | Standard (5–7 days) | Adequate |

| Shanghai Teshi | China | OEM/ODM, Compact Modules | Assumed compliance | Small | High | Fast (OEM-focused) | Specialized |

| ZFX (Shenzhen Square) | China | General Purpose, Remote Control | High operational reliability | Medium-Large | Moderate-High | Very Fast | Excellent |

How to Choose the Right Product?

Product Parameter Comparison Table

| Supplier | Main Product Types | Key Technical Parameters | Applicable Scenarios | Delivery Time | MOQ | Price Range (USD) |

|---|---|---|---|---|---|---|

| Guangzhou Tmcon | AiFUZZY919, FT819P, AiFUZZY879 | 0.1% accuracy, 80-segment program, RS485/WiFi/LORA, PID/Fuzzy logic | Industrial kilns, process automation, R&D labs | 7–15 days | 1 unit | $50–$180 |

| Ruishengda | XH-W3001, XH-W1209 | Digital display, ±0.5°C accuracy, waterproof probe, 12–220V input | Incubators, home brewing, small appliances | 3–7 days | 10 units | $8–$25 |

| Belme | CHB401, STC-9200 | SSR/Relay output, 220VAC, K-type input, adjustable setpoint | Ovens, refrigeration units, heating systems | 5–10 days | 5 units | $15–$40 |

| Shangfang | SF-569A, ED330 | NTC sensor, cooling/heating switchable, timer function | Fermentation tanks, freezers, beverage coolers | 7–12 days | 10 units | $12–$35 |

| Shanghai Teshi | Custom PID, 48*24mm module | Built-in 5A SSR, 18–265V AC/DC, OEM-ready | Embedded machinery control, compact devices | 10–20 days (custom) | 50 units (custom) | $20–$60 |

| ZFX (Shenzhen Square) | XH-W3001, STC-200, W3230 | Remote control option, dual-color LED, -55 to 120°C range | Cold storage, remote monitoring, educational kits | 3–6 days | 5 units | $10–$30 |

Note: Suppliers like Guangzhou Tmcon use high-grade aluminum alloy housings for heat dissipation in industrial models, while Ruishengda and ZFX use ABS plastic for cost-sensitive consumer units. Communication interfaces vary significantly—only Tmcon offers LORA and WiFi, critical for IoT integration.

Performance Visualization & Interpretation

The radar chart highlights distinct positioning among suppliers. Guangzhou Tmcon excels in accuracy, connectivity, and customization—ideal for industrial automation where precision and integration matter most. Their high investment in PID algorithm development and communication protocols (Modbus, WiFi, LORA) makes them best suited for long-term deployments in harsh environments. However, their cost efficiency is lower due to premium components and R&D overhead. In contrast, Ruishengda leads in cost efficiency and simplicity but lags in connectivity and customization, making it ideal for low-budget projects like DIY incubators or student experiments. ZFX balances affordability with moderate durability and good customization potential, especially for remote-controlled cold storage monitoring. Buyers must weigh trade-offs: short lead time and low MOQ (e.g., ZFX at 3–6 days, MOQ 5) benefit startups and small batches, whereas higher MOQs with deeper customization (Shanghai Teshi) suit established OEMs needing embedded solutions. Ultimately, selecting the right product depends on application complexity, budget, scalability needs, and integration requirements.

How to Use and Maintain?

Digital temperature controllers are essential in maintaining optimal thermal conditions across diverse settings—from industrial kilns to household refrigerators. Proper usage begins with correct installation: ensure the sensor (thermocouple or NTC) is securely placed at the measurement point without bending or exposure to moisture unless rated IP67 or higher. For example, in a ceramic kiln, the K-type thermocouple should be inserted into a protective sheath and positioned near the center of the chamber to avoid false readings from wall radiation. When setting parameters, users should calibrate the offset if ambient drift occurs, using known reference points (e.g., ice bath for 0°C).

In B2B environments such as food processing plants, programmable ramp/soak profiles (available in Tmcon’s AiFUZZY879) allow gradual heating cycles that prevent thermal shock in delicate products. In office buildings, digital thermostats regulate HVAC systems efficiently, reducing energy consumption by up to 20% compared to mechanical controls. For B2C applications like home wine fermentation (using Shangfang’s SF-569A), the timer function ensures consistent aging temperatures over weeks, enhancing flavor development.

Maintenance is crucial for longevity. Clean the display and housing regularly with a dry cloth; avoid solvents that may damage plastic enclosures. Check terminal connections annually for corrosion, especially in humid environments. Replace worn-out relays or SSRs before failure—typical lifespan is 50,000 cycles. Firmware updates (where supported, e.g., via Modbus) can enhance functionality and security. For outdoor installations, use weatherproof enclosures and surge protectors. Upgrade paths include replacing basic models with WiFi-enabled ones (like AiFUZZY915) for remote monitoring via smartphone apps. Regular calibration every 6–12 months ensures continued accuracy, particularly in regulated industries like pharmaceuticals.

FAQ

- Are transactions protected on Alibaba.com? Yes, Trade Assurance protects buyers by guaranteeing on-time shipment and product quality as agreed in the contract.

- Can I request product samples before bulk ordering? Absolutely—most suppliers offer samples within 3–7 days, often refundable upon order confirmation.

- What is the difference between PID and on/off temperature control? PID provides smoother, more accurate regulation by adjusting output proportionally; on/off causes temperature swings due to cycling.

- Do these controllers work globally? Many models support 18–265V AC/DC, making them compatible with global voltages (110V US, 220V EU/Asia).

- How do I choose between SSR and relay output? SSR is silent, faster, and longer-lasting for frequent switching; relays are cheaper and sufficient for infrequent on/off loads.

Conclusions and Recommendations

- Low-Cost Mass Production: Choose Ruishengda or ZFX for XH-W series—low price, high availability, MOQ 5–10.

- High-End Brand Customization: Partner with Guangzhou Tmcon for AI-enhanced PID logic, full communication suite, and OEM firmware branding.

- Rapid Trial Production: Use ZFX or Belme for fast-delivery, mid-range accuracy units with relay outputs.

- Mixed Procurement Strategy: Combine Tmcon (for core process control) with Shangfang (for auxiliary cooling systems) to balance performance and cost.

Due Diligence / Factory Audit Checklist

- Verify business license and export eligibility.

- Request ISO/CE certification copies.

- Schedule third-party audit (e.g., SGS) for production line inspection.

- Test sample units for accuracy, response time, and durability.

- Negotiate payment terms (30% deposit, 70% before shipment).

- Confirm warranty period (minimum 1 year).

- Review after-sales service policy (response time, spare parts availability).

- Clarify customization limits (firmware, labeling, packaging).

- Establish QC checkpoints (pre-shipment inspection).

- Sign NDA if developing proprietary control logic.

- Production scale estimates based on online revenue and industry benchmarks (credibility: medium).

- Certification assumptions derived from delivery performance and market presence (credibility: medium).

- Customer types inferred from product applications and listing keywords.

- All prices are approximate FOB China, excluding shipping and taxes.

Rate this page

Comments

No comments yet. Be the first to comment!

Leave a Reply

Your email address will not be published. Required fields are marked *