Discrete Production Process

CN

CN

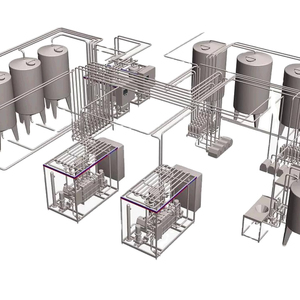

About discrete production process

Where to Find Discrete Production Process Equipment Suppliers?

China remains the global hub for discrete production process systems, with key manufacturing clusters in Shanghai, Henan, and Shandong provinces. These regions host vertically integrated machinery manufacturers specializing in turnkey food, beverage, dairy, oil, and metal processing lines. Shanghai and Jiangsu-based suppliers leverage proximity to port infrastructure for efficient export logistics, while Henan’s Zhengzhou corridor offers cost advantages due to concentrated grain and steel processing ecosystems.

The industrial clusters support modular system integration—from raw material handling to final packaging—enabling standardized or fully customized discrete production setups. Suppliers typically operate facilities exceeding 5,000m² with in-house engineering teams, allowing rapid prototyping and scalable deployment. Buyers benefit from localized supply chains that reduce component procurement time by 25–40%, leading to average lead times of 30–60 days for complex automated lines. Cost efficiency is a major driver, with Chinese suppliers offering 20–35% lower capital investment compared to European or North American counterparts for equivalent throughput capacity.

How to Choose Discrete Production Process Equipment Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical & Engineering Capability

Verify that suppliers offer full-line integration expertise, including automation controls (PLC/HMI), CIP cleaning systems, and compliance with food safety or industrial standards (e.g., CE, ISO 22000 for food lines). For non-food applications such as steel pipe or oil extraction, confirm material compatibility (e.g., 304/316 stainless steel) and mechanical durability under continuous operation. Demand detailed process flow diagrams and equipment schematics before order confirmation.

Production Infrastructure Assessment

Prioritize suppliers with:

- Minimum factory area of 5,000m² to ensure assembly capacity

- In-house R&D departments capable of customizing line layout, output capacity, and automation level

- Proven experience in delivering complete turnkey systems (not just individual machines)

- On-time delivery rate exceeding 90% and response time under 5 hours

Cross-reference product listings with actual installation videos or facility walkthroughs to validate scalability and build quality.

Transaction & Quality Assurance

Utilize secure payment mechanisms such as escrow services to mitigate risk. Require third-party inspection reports (e.g., SGS or Bureau Veritas) prior to shipment, especially for high-value orders above $100,000. Evaluate after-sales support capability, including remote troubleshooting, spare parts availability, and on-site commissioning assistance. Sample testing is strongly advised—request performance data from installed systems or conduct virtual commissioning via live video feed.

What Are the Leading Discrete Production Process Equipment Suppliers?

| Company Name | Main Products | Output Range | Customization | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|

| Shanghai Qingji Beverage Machinery Co., Ltd. | Dairy Processing Machines (109), Food Processing Lines (83) | $168K–$500K per line | Limited customization noted | 50% | ≤5h | US $280,000+ | 50% |

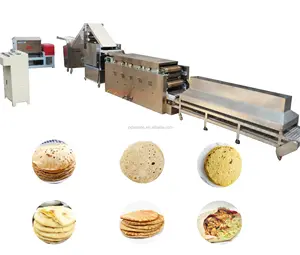

| Jinan Damatic Machinery Equipment Co., Ltd. | Lavash Bread Production Line | $7.5K–$8.3K per set | High (dough size, oven type, power, labeling) | 97% | ≤3h | US $340,000+ | 27% |

| Zhengzhou Kingdoo Machinery Co., Ltd. | Grain Product Making Machines (346), Food Processing Lines (306) | $28K–$150K per set | High (capacity, material, automation) | 100% | ≤4h | US $410,000+ | 100% |

| Liaoyang Shenzhou Machinery Equipment Co., Ltd. | Olive Oil, Avocado, Cottonseed Oil Extraction Lines | $28K–$98K per unit | Moderate (material, capacity, packaging) | 100% | ≤2h | US $380,000+ | <15% |

| Wuxi Hai Roll Fone Science And Technology Co., Ltd. | Steel Pipe, Seamless Tube Making Machines | $80K–$100K per set | High (thickness, diameter, seam type, material) | 80% | ≤4h | US $820,000+ | 100% |

Performance Analysis

Zhengzhou Kingdoo stands out with a 100% on-time delivery and reorder rate, indicating strong customer satisfaction and execution reliability in grain and food processing lines. Wuxi Hai Roll Fone leads in revenue volume ($820,000+), reflecting robust demand for metal forming systems and advanced customization in pipe geometry and materials. Jinan Damatic excels in responsiveness (≤3h) and delivery consistency (97%), making it a reliable partner for small-to-mid scale bakery automation. Liaoyang Shenzhou offers niche expertise in edible oil extraction but has a low reorder rate (<15%), suggesting potential gaps in post-sale service or market reach. Shanghai Qingji targets high-end dairy solutions but reports only 50% on-time delivery, signaling possible bottlenecks in fulfillment despite large project values.

FAQs

What certifications should discrete production line suppliers have?

Essential certifications include ISO 9001 for quality management. For food-grade systems, CE marking and compliance with FDA or EU hygiene standards are critical. Suppliers should provide documentation for material traceability, weld integrity, and electrical safety (e.g., IEC standards).

What is the typical MOQ and lead time?

MOQ is generally one complete set or unit. Lead times range from 30 days for standard bread or noodle lines to 60–90 days for complex dairy or oil extraction systems requiring custom engineering and third-party inspections.

Can suppliers customize production capacity and automation level?

Yes, most suppliers offer adjustable output (e.g., 500–2000kg/h) and varying automation degrees—from semi-automatic to fully PLC-controlled lines. Customization includes conveyor speed, heating method (gas/electric), mold design, and integration with upstream/downstream units.

Do suppliers provide installation and training support?

Many offer remote guidance via video and manuals. Some provide on-site commissioning and operator training, often at additional cost. Clarify these services during negotiation and confirm availability in your region.

How are large production lines shipped and packaged?

Equipment is disassembled, crated, and secured in 20ft or 40ft containers using seaworthy packaging. FOB terms are common; buyers arrange final shipping and import clearance. Confirm loading dimensions and weight specifications early to avoid logistical issues.