Door Frame Maker

1/27

1/27

1/8

1/8

1/18

1/18

1/10

1/10

1/24

1/24

1/31

1/31

1/6

1/6

CN

CN

1/18

1/18

1/27

1/27

1/29

1/29

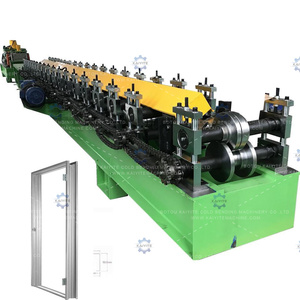

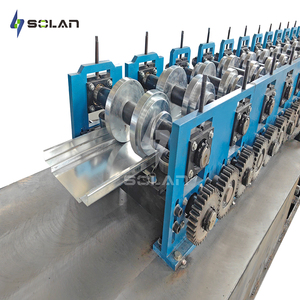

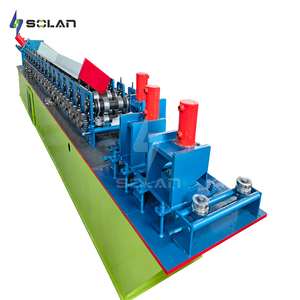

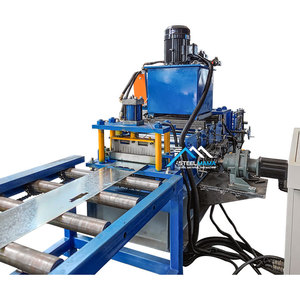

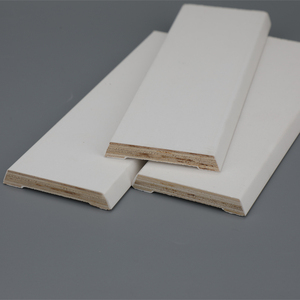

About door frame maker

Where to Find Door Frame Maker Suppliers?

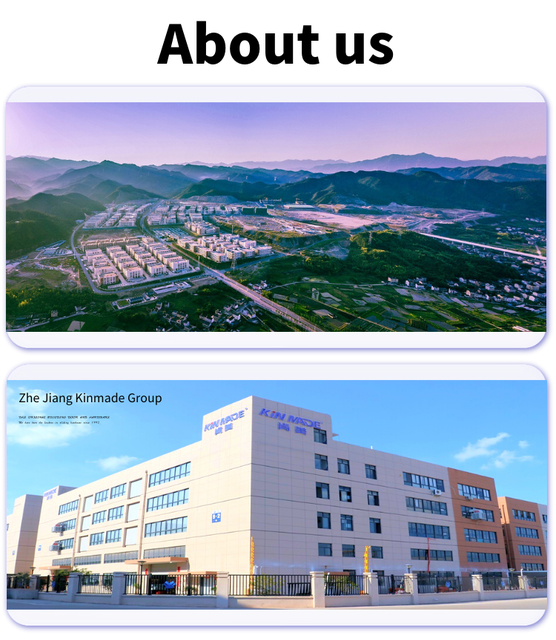

China remains the global hub for door frame manufacturing equipment and fabricated components, with key production clusters in Guangdong, Jiangsu, and Hebei provinces. Foshan in Guangdong specializes in aluminum and WPC (wood-plastic composite) door frame systems, supported by a dense network of extrusion, surface treatment, and fabrication facilities. Zhangjiagang in Jiangsu focuses on integrated machinery lines for WPC and steel door frames, leveraging regional expertise in cold-forming and automation technology. Hebei’s Botou region is known for cost-effective steel and iron-based door frame production, particularly for fire-rated and industrial applications.

These industrial zones benefit from vertically integrated supply chains—enabling rapid sourcing of raw materials like aluminum billets, galvanized steel coils, and PVC composites—reducing lead times by 20–30% compared to fragmented markets. Suppliers within these clusters typically operate full-cycle production capabilities, including CNC cutting, bending, welding, and surface finishing, allowing for efficient scale-up. Buyers can expect standard lead times of 30–45 days for machinery orders and 15–25 days for component shipments, depending on customization level and order volume.

How to Choose Door Frame Maker Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

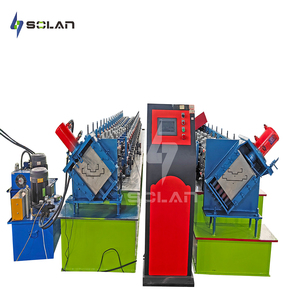

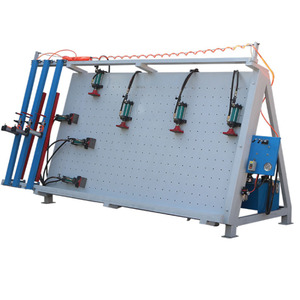

Production Capabilities

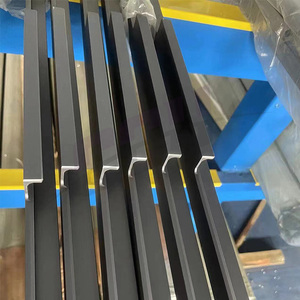

Assess whether suppliers possess in-house production lines and engineering support. Key indicators include dedicated R&D teams, automated assembly processes, and facility sizes exceeding 3,000m² for machinery manufacturers. For component suppliers, verify access to extrusion presses, anodizing lines, or roll-forming systems based on material type (aluminum, steel, WPC).

Quality Assurance & Compliance

Prioritize suppliers with ISO 9001 certification as a baseline for quality management. For export to regulated markets, confirm compliance with CE, RoHS, or local building codes (e.g., ASTM E2010 for fire resistance). Request test reports for mechanical strength, corrosion resistance, and dimensional accuracy, especially for load-bearing frames.

Customization & Technical Support

Evaluate flexibility in material selection, profile design, color finishes, and packaging. Leading suppliers offer CAD/CAM-based customization, logo branding, and modular machine configurations. Confirm availability of pre-shipment testing, installation guidance, and remote troubleshooting support.

Transaction Reliability

Analyze verified performance metrics: target on-time delivery rates above 97%, response times under 5 hours, and reorder rates exceeding 25%. Use secure payment mechanisms such as escrow services and require sample validation before bulk orders. Conduct virtual factory audits to verify claimed infrastructure and production workflows.

What Are the Best Door Frame Maker Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Price Range (Min Order) |

|---|---|---|---|---|---|---|---|---|

| Zhangjiagang Anda Machinery Co., Ltd. | Jiangsu, CN | Custom Manufacturer | US $300,000+ | 100% | ≤5h | 50% | WPC Door Frame Machines | $38,000–40,000/set |

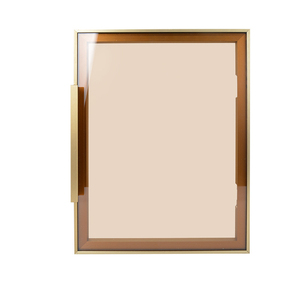

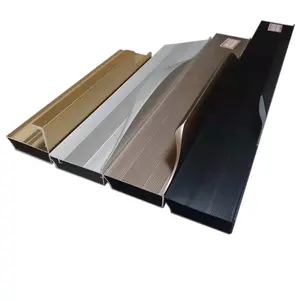

| Foshan Waybom Aluminum Co., Ltd. | Guangdong, CN | Multispecialty Supplier | US $170,000+ | 100% | ≤9h | 33% | Aluminum Door Profiles | $1.29–3.41/kg or m |

| TIANJIN FRAME METAL MANUFACTURING CO., LTD. | Tianjin, CN | Multispecialty Supplier | US $170,000+ | 100% | ≤2h | <15% | Aluminum & Steel Doors | $60–140/sqm |

| Foshan Liding Machine Equipment Co., Ltd. | Guangdong, CN | Not Specified | US $10,000+ | 100% | ≤4h | Unreported | Steel Door Frame Machines | $12,000–31,000/set |

| Botou Kaiyite Cold Bending Machinery Co., Ltd. | Hebei, CN | Custom Manufacturer | US $150,000+ | 100% | ≤3h | 25% | Steel & Aluminum Frame Machines | $6,800–17,500/set |

Performance Analysis

Zhangjiagang Anda Machinery stands out with the highest online revenue and a 50% reorder rate, indicating strong customer retention in the WPC machinery segment. Its fully integrated production line supports turnkey solutions for composite door manufacturing. Foshan Waybom offers competitive pricing on aluminum profiles with high customization breadth, serving niche architectural and interior projects. TIANJIN FRAME METAL demonstrates fast responsiveness (≤2h) but lower repeat business, suggesting potential gaps in post-sale service or consistency. Among machinery providers, Botou Kaiyite delivers scalable solutions at lower price points, ideal for startups or regional producers. Foshan Liding offers mid-range steel framing equipment with solid delivery performance despite limited sales volume visibility.

FAQs

How to verify door frame maker supplier reliability?

Cross-check ISO certifications and request audit trails for raw material sourcing and quality control procedures. Review verifiable transaction histories, focusing on on-time delivery records and dispute resolution outcomes. Conduct video inspections of production floors to validate machinery and workforce capacity.

What is the typical MOQ and lead time?

For machinery, MOQ is typically 1 set with lead times of 30–45 days. Component suppliers (e.g., aluminum profiles) may require 10–60kg or meters, with fulfillment in 15–25 days. Bulk orders may reduce unit costs by 10–20%.

Can suppliers customize door frame designs?

Yes, most suppliers support customization in dimensions, materials (aluminum, steel, WPC), surface finishes (powder coating, anodizing), and structural features (thermal breaks, sound insulation). Provide technical drawings or specifications for accurate quoting.

Do manufacturers provide samples?

Sample policies vary. Some suppliers offer free samples for qualified buyers committing to future orders. Others charge nominal fees recoverable against first purchases. Expect 7–14 days for sample production and 5–10 days for international shipping.

What are common payment and shipping terms?

Standard terms include T/T (30% deposit, 70% before shipment) or Letter of Credit. FOB terms are common; CIF options available upon request. Sea freight is optimal for heavy machinery and large batches, while air freight suits urgent sample deliveries.