Double Deep Racking System

1/20

1/20

CN

CN

1/17

1/17

CN

CN

1/23

1/23

1/26

1/26

1/23

1/23

CN

CN

1/30

1/30

1/40

1/40

1/18

1/18

HK

HK

1/16

1/16

CN

CN

1/21

1/21

1/24

1/24

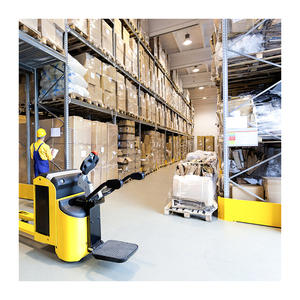

About double deep racking system

Where to Find Double Deep Racking System Suppliers?

China remains the central hub for industrial storage solutions, with key manufacturing clusters concentrated in Guangdong and Shanghai. These regions host vertically integrated steel fabrication ecosystems, enabling efficient production of high-capacity double deep racking systems. Guangzhou-based suppliers benefit from proximity to major ports like Nansha and Huangpu, reducing logistics lead times by 10–15% compared to inland facilities. Shanghai’s industrial base leverages advanced cold-rolling and galvanization technologies, supporting precision-engineered components that meet international load-bearing standards.

The clustering effect allows suppliers to maintain tight control over material sourcing, fabrication, and assembly—critical for structural integrity in pallet racking applications. Buyers gain access to streamlined supply chains where raw steel, punching dies, coating materials, and packaging are sourced within 50 km. This integration supports faster turnaround (average 20–30 days for standard orders), cost efficiency (20–30% below Western market rates), and flexibility for large-scale or engineered-to-order projects.

How to Choose Double Deep Racking System Suppliers?

Procurement decisions should be guided by rigorous evaluation criteria focused on technical compliance, production capacity, and transaction reliability:

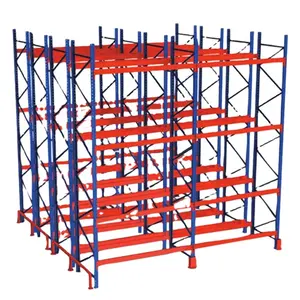

Structural Integrity & Certification

Confirm adherence to recognized engineering standards such as FEM 10.2.02, ANSI MH16.1, or AS4084. While not all suppliers list ISO 9001 certification explicitly, verify whether quality management systems govern design validation, weld inspection, and load testing protocols. Request deflection test reports and finite element analysis (FEA) documentation for custom configurations.

Manufacturing Capability Assessment

Evaluate core operational metrics:

- Minimum monthly output exceeding 100,000 kg to support bulk procurement

- In-house processing capabilities including roll forming, robotic welding, hole-punching, and electrostatic painting

- Material traceability for Q235/Q345-grade steel with options for hot-dip galvanizing or powder coating

Cross-reference supplier claims with delivery performance—target on-time fulfillment rates ≥95%.

Customization & Transaction Security

Prioritize suppliers offering dimensional adaptability (bay depth, beam length, upright height) and labeling/packaging personalization. Use secure payment mechanisms such as escrow services, especially when engaging newer vendors. Conduct pre-shipment inspections via third-party auditors to validate load capacity, surface treatment quality, and dimensional accuracy against specifications.

What Are the Best Double Deep Racking System Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Rack Design Commercial Equipment Co., Ltd. | Guangzhou, CN | US $40,000+ | 100% | ≤2h | <15% | 1 set | $49.60–55 | None listed |

| Guangzhou Heda Warehouse Equipment Co., Ltd. | Guangzhou, CN | US $50,000+ | 100% | ≤4h | 42% | 10 sets | $48–88 | Color, material, size, logo, packaging, label, graphic |

| Shanghai Nuoteng Storage Shelf Manufacturing Co., Ltd. | Shanghai, CN | US $210,000+ | 71% | ≤2h | 28% | 1 kg | $0.83–0.85/kg | Color, thickness, weight, type, load, material, size, drawings, design, legs, assembly, graphic, frame, galvanized, height |

| Guangzhou Heda Intelligent Warehousing Equipment Co., Ltd. | Guangzhou, CN | US $60,000+ | 100% | ≤3h | 25% | 20 pieces | $25–45 | Color, material, size, logo, packaging, label, graphic |

| Guangdong Haili Storage Technology Co., Ltd. | Guangdong, CN | US $60,000+ | 100% | ≤3h | 100% | 50 sets | $45–80 | None listed |

Performance Analysis

Guangzhou-based suppliers dominate responsiveness and reliability, with three achieving 100% on-time delivery. Guangdong Haili stands out with a 100% reorder rate—indicative of strong post-sale satisfaction—though it requires higher MOQs (50 sets). Shanghai Nuoteng offers the most extensive customization range and lowest per-kilogram pricing, making it ideal for OEM integrators despite its lower delivery consistency (71%). Guangzhou Heda Warehouse and Intelligent Warehousing divisions both offer mid-range pricing with robust customization, but differ in order structure—one favors volume (10+ sets), the other modular units (20+ pieces).

FAQs

How to verify double deep racking system supplier reliability?

Validate technical capabilities through factory audit reports, video tours of production lines, and sample load tests. Check for documented quality control procedures, including weld inspections and coating thickness measurements. Analyze transaction history focusing on dispute resolution, shipment accuracy, and customer retention rates.

What is the typical lead time for double deep racking systems?

Standard orders typically ship within 20–30 days after confirmation. Customized configurations involving non-standard dimensions or galvanized finishes may extend lead times to 45 days. Expedited production (12–15 days) is available from select suppliers at a premium.

Can suppliers provide free samples?

Full-system samples are uncommon due to size and freight costs. However, many suppliers offer component samples (e.g., upright frames or beams) at nominal fees, which may be credited toward first orders. Expect sample charges covering material and processing costs, typically $50–$150 per piece.

Do manufacturers support global shipping?

Yes, established suppliers routinely export to North America, Europe, Australia, and Southeast Asia. Confirm Incoterms (FOB, CIF, DDP), container loading plans, and destination compliance requirements. Most use 20' or 40' HC containers with flat-packed configurations to maximize space utilization.

How to initiate a customization request?

Submit detailed specifications including required bay depth, beam length, upright height, load capacity per level, and desired finish (pre-galvanized, post-galvanized, or painted). Reputable suppliers will respond with CAD drawings, structural calculations, and prototype timelines within 3–5 business days.