Dr Cortex

1/1

1/1

1/3

1/3

1/3

1/3

1/5

1/5

0

0

1/3

1/3

1/2

1/2

1/18

1/18

0

0

1/3

1/3

1/3

1/3

1/4

1/4

1/3

1/3

1/7

1/7

1/3

1/3

1/3

1/3

About dr cortex

Where to Find Dr Cortex Suppliers?

No verified suppliers for "Dr Cortex" were identified in the current industrial manufacturing databases. The term does not correspond to a recognized product category within medical, cosmetic, or industrial equipment classifications tracked in major sourcing regions such as China’s Guangdong, Zhejiang, or Jiangsu provinces—areas typically dominant in dermatological device and aesthetic machinery production.

Given the absence of structured supplier data, procurement professionals should verify whether "Dr Cortex" refers to a proprietary brand name, an obsolete product line, or a miscommunication of intended equipment (e.g., skin resurfacing devices, radiofrequency microneedling systems, or dermal delivery platforms). In cases involving niche or patented technologies, direct engagement with original design manufacturers (ODMs) specializing in electro-medical apparatus is recommended. These facilities are commonly clustered near Shenzhen and Shanghai, where regulatory-compliant production lines support ISO 13485-certified medical device assembly.

How to Choose Dr Cortex Suppliers?

In the absence of active suppliers, due diligence must focus on identifying technically aligned manufacturers capable of producing equivalent high-frequency dermatological treatment systems. When evaluating potential partners for similar devices, apply the following verification protocols:

Technical Compliance

Confirm adherence to medical device quality standards, including ISO 13485 certification for design and manufacturing processes. For export to regulated markets (EU, USA, Canada), CE marking under MDD/IVDD or FDA 510(k) clearance documentation is essential. Request test reports for electromagnetic compatibility (EMC), electrical safety (IEC 60601-1), and biocompatibility if applicable.

Production Capability Audits

Assess core competencies in precision electronics integration, thermal management systems, and user-interface controls. Key indicators include:

- Minimum 3,000m² cleanroom-compatible facility area

- Dedicated R&D teams with experience in RF, laser, or pulsed light technologies

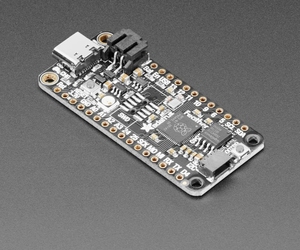

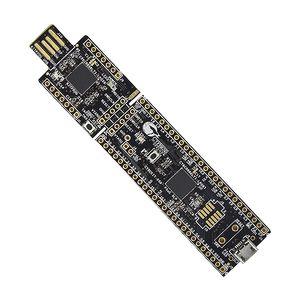

- In-house PCB assembly and software validation capabilities

Validate scalability through historical order fulfillment metrics, targeting on-time delivery rates above 95%.

Transaction Safeguards

Utilize secure payment structures such as letter of credit (L/C) or third-party escrow until post-delivery performance verification. Review audit trails via independent inspection agencies (e.g., SGS, TÜV) to confirm conformance with technical specifications. Pre-shipment testing should include functional trials, cycle durability checks, and calibration accuracy assessments.

What Are the Best Dr Cortex Suppliers?

No supplier data matching “Dr Cortex” is currently available in global B2B registries. The table below reflects this informational gap:

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| No suppliers found for "Dr Cortex". Consider verifying product nomenclature or expanding search to ODMs specializing in aesthetic medical devices. | ||||||||

Performance Analysis

Without identifiable suppliers, procurement strategies should shift toward qualified manufacturers of comparable energy-based skincare systems. Focus on firms with documented export experience to North America and Europe, particularly those with prior work in fractional RF, micro-needling, or non-ablative resurfacing technology. Prioritize companies that provide full traceability of components, firmware version control, and compliance with country-specific labeling requirements.

FAQs

How to verify Dr Cortex supplier reliability?

Since no suppliers are listed, initiate verification by confirming the correct product classification and technical specifications. Cross-reference any claims with trademark databases, patent filings, or regulatory listings (e.g., FDA’s Device Classification Database). Engage third-party auditors to assess manufacturer legitimacy when contact information becomes available.

What is the average sampling timeline?

Sampling timelines cannot be determined without active suppliers. However, for equivalent medical aesthetic devices, expect standard sample development cycles of 30–45 days, inclusive of configuration, firmware setup, and safety testing. Air freight adds 7–12 days depending on destination.

Can suppliers ship machinery worldwide?

Qualified medical device manufacturers typically support global shipments under FOB, CIF, or DDP terms. Ensure exporters possess experience navigating customs clearance for Class II medical devices and can supply necessary documentation: certificate of origin, bill of lading, technical file summaries, and conformity declarations.

Do manufacturers provide free samples?

Free samples are uncommon for high-value medical equipment. Most manufacturers require cost recovery for sample units, often refundable against future bulk orders. Budget approximately 40–60% of unit cost for prototype evaluation models.

How to initiate customization requests?

Submit detailed technical dossiers including desired output parameters (frequency, pulse duration, power range), handpiece ergonomics, touchscreen interface preferences, and regulatory target markets. Reputable manufacturers will respond with feasibility assessments, risk analysis, and preliminary design mockups within 5–7 business days.