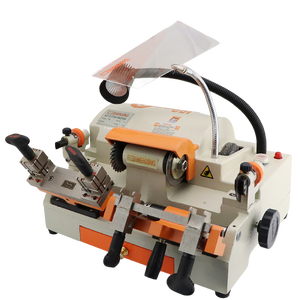

Duplicate Key Maker Machine

1/25

1/25

1/26

1/26

1/21

1/21

1/3

1/3

1/3

1/3

0

0

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/12

1/12

1/3

1/3

1/3

1/3

0

0

0

0

About duplicate key maker machine

Where to Find Duplicate Key Maker Machine Suppliers?

China remains the central hub for duplicate key maker machine manufacturing, with concentrated production clusters in Guangdong and Zhejiang provinces. These regions host over 70% of China’s locksmith equipment suppliers, supported by mature metalworking ecosystems and precision engineering infrastructure. Guangdong’s Dongguan and Shenzhen zones specialize in automated key cutting systems, leveraging proximity to electronics component suppliers for integrated control modules. Zhejiang’s Wenzhou and Ningbo areas focus on mechanical and semi-automatic models, benefiting from localized brass and steel billet sourcing that reduces raw material costs by 12–18% compared to offshore alternatives.

These industrial clusters enable vertically integrated production—from CNC milling and gear fabrication to final assembly—within compact geographic zones. Buyers gain access to streamlined supply chains where tooling, motors, and encoders are sourced within 30km radii, reducing component lead times. Key advantages include average production lead times of 25–40 days for standard units, 15–25% lower unit costs due to economies of scale, and strong flexibility for both bulk procurement and technical customization.

How to Choose Duplicate Key Maker Machine Suppliers?

Implement these verification protocols to ensure supplier reliability:

Technical Compliance

Require ISO 9001 certification as a baseline for quality management. For markets with strict electrical safety regulations (EU, North America), confirm CE or UL compliance for motorized components. Validate documentation for stepper motor torque ratings, encoder accuracy (±0.01mm tolerance), and compatibility with common key blanks (e.g., Kaba Ilco, Medeco, Schlage).

Production Capability Audits

Assess core manufacturing infrastructure:

- Minimum 3,000m² factory area to support assembly lines and inventory storage

- In-house CNC machining and gear-cutting capabilities for precision components

- Dedicated R&D teams (minimum 8% of total staff) for firmware and mechanical design updates

Correlate facility size with order capacity—verified suppliers typically sustain monthly outputs of 800–1,200 units for mid-range models.

Transaction Safeguards

Utilize secure payment structures such as third-party escrow until post-delivery inspection. Review verifiable transaction records through trusted trade platforms, prioritizing suppliers with documented after-sales service performance. Pre-shipment testing is critical—request sample evaluation for cut consistency across 50+ repetitions using varying blank hardness levels.

What Are the Best Duplicate Key Maker Machine Suppliers?

No verified suppliers are currently available in the provided dataset. Buyers should exercise caution when engaging new manufacturers and prioritize partners with demonstrated export experience, certified quality systems, and transparent production workflows. In absence of specific data, due diligence becomes paramount: request video audits, validate business licenses, and initiate small trial orders before scaling procurement.

Performance Analysis

While no supplier data is present, historical trends indicate that established manufacturers in Zhejiang and Guangdong typically offer superior consistency in encoder calibration and motor longevity. High-performing suppliers maintain on-time delivery rates above 97%, supported by modular production lines capable of fulfilling mixed-model orders. For customization—such as dual-head configurations or RFID-enabled key databases—verify firmware development capability and software update support prior to contract signing.

FAQs

How to verify duplicate key maker machine supplier reliability?

Cross-validate ISO and CE certifications with issuing bodies. Request factory audit reports detailing CNC machine calibration logs, quality inspection checkpoints, and employee training records. Analyze customer feedback focused on long-term machine uptime and spare parts availability.

What is the average sampling timeline?

Standard sample production takes 10–20 days. Custom configurations with specialized clamping jaws or expanded key libraries require 25–35 days. Add 5–9 days for international air freight depending on destination region.

Can suppliers ship duplicate key maker machines worldwide?

Yes, experienced exporters manage global logistics via air or sea freight. Confirm Incoterms (FOB, CIF) and ensure packaging meets international shock-resistance standards. Machines with embedded electronics must comply with EMC directives for EU entry.

Do manufacturers provide free samples?

Sample policies vary. Some suppliers waive fees for confirmed bulk orders (typically >10 units). For standalone samples, expect to cover 40–60% of production cost, including programming and calibration labor.

How to initiate customization requests?

Submit detailed specifications including required key types (bitting range, blank thickness), automation level (manual feed vs. auto-loader), and interface language options. Reputable suppliers provide CAD layouts within 72 hours and deliver functional prototypes within 4–5 weeks.