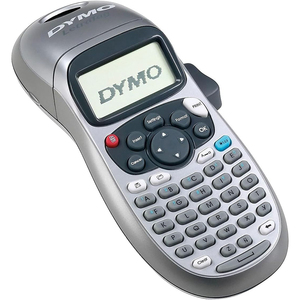

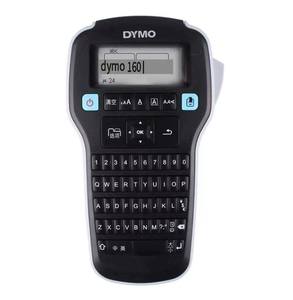

Dymo Plug And Play Label Maker

1/28

1/28

1/38

1/38

1/23

1/23

1/23

1/23

1/18

1/18

1/26

1/26

1/30

1/30

1/7

1/7

1/10

1/10

About dymo plug and play label maker

Where to Find DYMO Plug and Play Label Maker Suppliers?

China remains a central hub for compact thermal labeling equipment, with key manufacturing clusters in Guangdong, Jiangsu, and Shandong provinces. Shenzhen and Guangzhou-based suppliers dominate production of handheld, plug-and-play label makers compatible with DYMO formats, leveraging established electronics supply chains and high-volume component availability. These regions host vertically integrated facilities capable of assembling complete devices—including PCBs, casing molds, and thermal print engines—within localized ecosystems, reducing material lead times by 20–30% compared to offshore alternatives.

The industrial advantage lies in modular design frameworks that support rapid configuration of plug-and-play functionality, USB connectivity, and battery-powered operation. Suppliers benefit from proximity to raw material sources for ABS plastic, lithium-ion cells, and thermal ribbon/tape components, enabling cost-efficient production cycles. Average manufacturing lead times range from 15–25 days for standard orders, with express fulfillment options available for pre-stocked models. Buyers gain access to flexible MOQ structures, ranging from single-unit test orders to container-scale shipments, supported by digital procurement platforms with verified transaction histories.

How to Choose DYMO Plug and Play Label Maker Suppliers?

Procurement decisions should be guided by systematic evaluation of technical, operational, and transactional performance indicators:

Technical Compatibility & Design Validation

Confirm device compatibility with DYMO D1, LetraTag, or LabelManager tape formats where interoperability is required. Evaluate firmware integration for plug-and-play USB connectivity and driver-free installation on Windows/macOS systems. Request product specifications detailing print resolution (typically 203–300 dpi), tape width support (6mm–12mm), and power source (battery vs. USB-powered).

Production and Quality Assurance Protocols

Prioritize suppliers with documented quality management practices. While ISO 9001 certification is not universally listed, consistent on-time delivery rates above 97% and low reorder rates indicate reliable process control. Assess manufacturing scale through facility size proxies such as monthly output capacity and workforce size. Key capabilities include in-house injection molding, SMT assembly lines, and final product testing under variable temperature and humidity conditions to ensure durability.

- Target suppliers with response times ≤3 hours for timely communication

- Verify on-time delivery performance ≥96% to minimize supply chain disruption

- Confirm minimum order flexibility—some suppliers offer MOQs as low as 1 piece for sample validation

Customization and Compliance Verification

Multiple suppliers offer customization options including color variants, logo printing, packaging design, and label material selection. For export markets, ensure compliance with IEC 60950 safety standards for information technology equipment and RoHS directives for restricted substances. Although CE/UL certification is not explicitly stated in all listings, buyers should request test reports or third-party compliance documentation prior to bulk ordering.

Transaction Security and Sampling Strategy

Utilize secure payment mechanisms such as escrow services to mitigate risk during initial engagements. Sample testing is critical—evaluate print clarity, tape adhesion, button responsiveness, and battery life across real-world use cases before scaling procurement. Average sampling lead time ranges from 3–7 days for ready-to-ship units, with customized prototypes requiring 10–14 days depending on complexity.

What Are the Best DYMO Plug and Play Label Maker Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Key Offerings | MOQ Range |

|---|---|---|---|---|---|---|---|---|

| Shenzhen KBF Electronics Co., Ltd. | Guangdong, CN | Custom Manufacturer | US $140,000+ | 97% | ≤3h | <15% | DYMO Executive 640CB, Industrial Time-Saving Keys Model | 1 set |

| Qingdao Applied Photonic Technologies Co., Ltd. | Shandong, CN | Custom Manufacturer | US $490,000+ | 100% | ≤1h | 30% | DYMO 160 Thermal Printer, Original LetraTag LT-100H Compatible | 10 pieces |

| Guangzhou Lanyou Electronic Technology Co., Ltd. | Guangdong, CN | — | US $20,000+ | 96% | ≤4h | 18% | P12 Wireless Inkless Printer, LT-100H Portable Models | 1–50 pieces |

| Nanjing Future Fiber Solutions Co., Ltd. | Jiangsu, CN | — | US $80,000+ | 100% | ≤2h | 24% | LabelManager 160/280 Rechargeable Models | 1 piece |

| Shenzhen Sailing Paper Co., Ltd. | Guangdong, CN | Multispecialty Supplier | US $20,000+ | 100% | ≤3h | 55% | Tape rolls, gold embossed labels, waterproof fanfold stacks | 100 rolls |

Performance Analysis

Qingdao Applied Photonic Technologies leads in responsiveness and reliability, achieving 100% on-time delivery and sub-one-hour average response times, making it ideal for urgent procurement cycles. Shenzhen KBF Electronics offers premium-grade models like the LabelManager Executive 640CB, targeting professional office environments with higher price points ($150/unit). Nanjing Future Fiber Solutions provides competitive per-unit pricing starting at $30 with no volume commitment, suitable for pilot testing. Notably, Shenzhen Sailing Paper Co., Ltd. specializes in consumables rather than hardware, with a high reorder rate (55%) indicating strong customer retention in label supply—a strategic partner for recurring tape needs. Buyers seeking full-system solutions should pair device manufacturers with dedicated tape suppliers to optimize lifecycle costs.

FAQs

How to verify DYMO plug and play label maker supplier reliability?

Cross-check declared specifications against physical samples. Analyze supplier metrics including on-time delivery rate, response time, and transaction volume. Request evidence of quality control processes such as incoming material inspection, burn-in testing, and final functional verification. Review customer feedback focusing on long-term device stability and tape compatibility consistency.

What is the typical MOQ for DYMO-compatible label makers?

MOQ varies significantly: some suppliers accept 1-piece trial orders, while others require 10–100 units for machine models. Tape roll suppliers often require 100-roll minimums. Negotiate tiered pricing based on volume brackets to optimize unit cost at scale.

Are customization options available for private labeling?

Yes, multiple suppliers offer OEM/ODM services including custom housing colors, branded packaging, logo engraving, and software interface modifications. Minimum thresholds typically start at 500 units for full customization, though label-only branding can begin at 1,000 rolls.

Can suppliers provide global shipping?

All listed suppliers support international delivery via express couriers (DHL, FedEx) or sea freight for bulk orders. Confirm Incoterms (FOB, CIF) upfront and verify import compliance requirements for electrical equipment in destination markets, particularly regarding voltage adapters and electromagnetic compatibility (EMC) standards.

How to initiate a sample request?

Contact suppliers directly with model specifications and intended application. Most offer paid samples (priced between $25–$150) that may be credited toward first production orders. Allow 3–7 business days for dispatch of in-stock units; add 7–10 days for custom-configured samples.