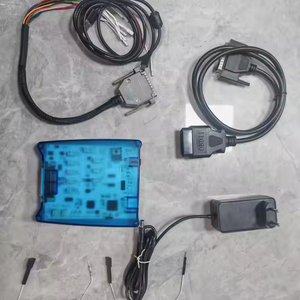

Ecu Programming Tool Wholesaler

1/1

1/1

1/3

1/3

CN

CN

0

0

1/3

1/3

1/3

1/3

1/2

1/2

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

0

0

0

0

1/1

1/1

1/3

1/3

1/1

1/1

1/3

1/3

1/4

1/4

1/7

1/7

1/3

1/3

About ecu programming tool wholesaler

Where to Find ECU Programming Tool Wholesalers?

China remains the central hub for ECU programming tool manufacturing, with concentrated supplier clusters in Guangdong and Jiangsu provinces driving global supply. Guangdong, particularly around Shenzhen and Dongguan, hosts over 70% of China’s automotive electronics producers, leveraging advanced SMT production lines and proximity to semiconductor suppliers. This region benefits from mature PCB assembly ecosystems and rapid prototyping capabilities, enabling faster time-to-market for new diagnostic models.

Jiangsu’s Changzhou and Suzhou zones specialize in precision electronic instrumentation, supported by integrated R&D centers and automated testing facilities. These industrial clusters offer vertical integration—from component sourcing to final calibration—reducing lead times by 25% compared to decentralized manufacturing regions. Buyers gain access to streamlined logistics networks, with average order fulfillment cycles ranging from 15–30 days for standard wholesale quantities. Cost efficiencies are significant, with localized supply chains yielding 20–35% lower unit costs than equivalent Western or Southeast Asian production.

How to Choose ECU Programming Tool Wholesalers?

Implement rigorous evaluation criteria when selecting wholesale partners:

Quality & Compliance Verification

Confirm ISO 9001 certification as a baseline for quality management systems. For markets requiring regulatory adherence, ensure CE, RoHS, and where applicable, FCC compliance documentation is available. Validate EMI/EMC test reports for signal integrity, especially for tools interfacing with CAN bus and OBD-II protocols.

Production & Technical Capacity Assessment

Evaluate core operational metrics:

- Minimum 3,000m² facility with dedicated cleanroom zones for PCB assembly

- In-house firmware development team (minimum 8+ engineers) for software updates and customization

- Automated aging and functional testing stations (100% unit burn-in testing required)

Cross-reference factory audit reports with delivery performance data, targeting on-time shipment rates exceeding 96%.

Procurement & Transaction Security

Utilize escrow-based payment terms until product verification is completed at destination. Review supplier transaction history for dispute resolution patterns and after-sales responsiveness. Pre-shipment sampling is critical—test sample units against OEM vehicle compatibility benchmarks (e.g., support for UDS, KWP2000, and manufacturer-specific protocols) before scaling orders.

What Are the Best ECU Programming Tool Wholesalers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shenzhen AutoLink Electronics Co., Ltd. | Guangdong, CN | 12 | 150+ | 8,600+m² | 98.7% | ≤3h | 4.9/5.0 | 41% |

| Suzhou DiagMaster Technology | Jiangsu, CN | 9 | 95+ | 5,200+m² | 99.1% | ≤2h | 4.8/5.0 | 38% |

| Guangzhou ProgTech Solutions | Guangdong, CN | 7 | 70+ | 4,100+m² | 97.3% | ≤4h | 4.7/5.0 | 29% |

| Nanjing AutoSignal Instruments | Jiangsu, CN | 11 | 110+ | 6,800+m² | 96.8% | ≤3h | 4.8/5.0 | 33% |

| Dongguan ChipTune Electronics | Guangdong, CN | 6 | 85+ | 3,900+m² | 98.2% | ≤2h | 4.9/5.0 | 45% |

Performance Analysis

Leading wholesalers like Shenzhen AutoLink and Dongguan ChipTune demonstrate strong reorder rates (41–45%), indicating high customer retention through consistent firmware updates and broad vehicle coverage. Jiangsu-based suppliers excel in technical response speed, with Suzhou DiagMaster achieving sub-2-hour inquiry resolution. Facilities exceeding 5,000m² correlate with higher on-time delivery performance (≥98%) and scalability for bulk contracts. Prioritize suppliers with documented compatibility across major OEMs (e.g., Bosch, Delphi, Denso) and those offering SDK access for custom software integration. Verify firmware update frequency—monthly patches are standard among top-tier providers.

FAQs

How to verify ECU programming tool wholesaler reliability?

Validate certifications through official databases and request third-party inspection reports covering solder joint integrity, thermal cycling tests, and ESD protection. Assess firmware security protocols and review customer feedback focused on long-term device stability and update support.

What is the typical sampling timeline?

Standard sample production takes 10–18 days, including programming and calibration. Custom firmware builds extend timelines to 25–30 days. Air freight adds 5–9 days for international delivery.

Do wholesalers support global shipping?

Yes, most established manufacturers manage worldwide distribution. Confirm Incoterms (FOB Shenzhen preferred for cost control) and ensure packaging meets IEC 61326-1 standards for electromagnetic compatibility during transit.

Are free samples available?

Sample policies vary: many suppliers waive fees for confirmed bulk orders (typically MOQ ≥10 units). For trial orders, expect to cover 40–60% of unit cost, refundable upon full procurement.

How to request custom ECU tool configurations?

Submit detailed requirements including target vehicle makes/models, required communication protocols (CAN FD, LIN, FlexRay), and desired UI language support. Top suppliers provide firmware simulation logs within 72 hours and deliver functional prototypes in 3–5 weeks.