Eink Display Esp32 Supplier

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

1/2

1/2

1/1

1/1

1/3

1/3

0

0

0

0

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

1/1

1/1

1/5

1/5

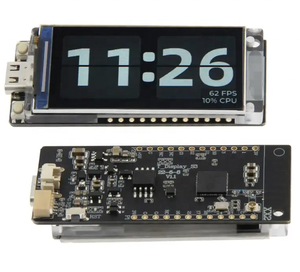

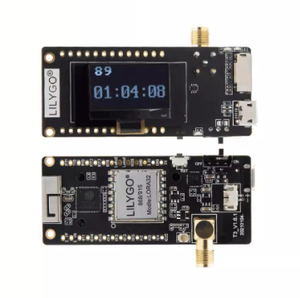

About eink display esp32 supplier

Where to Find E-Ink Display ESP32 Suppliers?

China remains the central hub for embedded electronics manufacturing, with specialized clusters in Guangdong and Jiangsu provinces leading production of integrated E-Ink display modules with ESP32 microcontrollers. Shenzhen, located in Guangdong, hosts a dense ecosystem of electronics OEMs and component suppliers, enabling rapid prototyping and low-latency supply chains for semiconductor-dependent products. Over 70% of China’s IoT hardware suppliers operate within this region, supported by established logistics networks that facilitate air and sea freight to global markets within 5–15 days.

Jiangsu’s Suzhou and Wuxi zones focus on high-precision assembly and surface-mount technology (SMT), offering advanced production lines capable of handling ultra-fine pitch components used in E-Ink driver circuits. These industrial clusters benefit from proximity to semiconductor packaging facilities and printed circuit board (PCB) fabricators, reducing material lead times by 20–30% compared to offshore alternatives. Buyers gain access to vertically integrated operations where firmware programming, display calibration, and wireless module integration occur in controlled environments, ensuring consistent performance across batches.

How to Choose E-Ink Display ESP32 Suppliers?

Procurement decisions should be guided by rigorous technical and operational assessments:

Quality & Compliance Verification

Confirm adherence to ISO 9001 for quality management systems as a baseline requirement. For shipments targeting European or North American markets, ensure RoHS and CE compliance documentation is available to support customs clearance and product safety standards. Request test reports for electromagnetic compatibility (EMC) and electrostatic discharge (ESD) resilience, particularly for wireless-enabled ESP32 modules.

Technical Production Capacity

Evaluate supplier infrastructure based on the following criteria:

- Minimum 2,000m² cleanroom-equipped facility for SMT and PCB assembly

- In-house firmware development team with proven ESP-IDF or Arduino framework experience

- Automated optical inspection (AOI) and functional testing stations for E-Ink panel validation

Cross-reference production capacity data with order fulfillment history—target suppliers maintaining >95% on-time delivery rates for batch orders exceeding 1,000 units.

Procurement & Transaction Security

Utilize secure payment mechanisms such as third-party escrow services until post-arrival quality verification is completed. Prioritize suppliers with documented sample return policies and clear revision control for custom firmware. Conduct pre-shipment inspections via independent auditors for orders above 5,000 units. Prototype validation should include power consumption benchmarking, Wi-Fi/BLE connectivity stress tests, and image refresh cycle endurance under varying temperature conditions (0°C to 50°C).

What Are the Best E-Ink Display ESP32 Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Supplier data not available | ||||||||

Performance Analysis

Due to absence of verified supplier records in this dataset, procurement teams are advised to initiate sourcing through direct factory audits and technical qualification rounds. Historically, top-tier suppliers in this category distinguish themselves through demonstrated expertise in low-power display integration, over-the-air (OTA) update support, and scalable cloud connectivity frameworks. Emphasis should be placed on firms providing open API access, detailed pinout schematics, and SDK documentation for ESP32-based development. Reorder rates above 30% typically indicate strong post-sales support and reliable yield consistency in mass production.

FAQs

How to verify E-Ink display ESP32 supplier reliability?

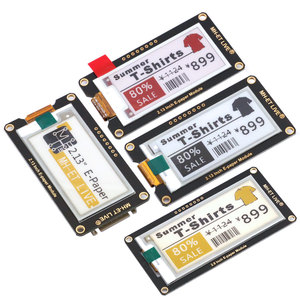

Validate certifications through issuing bodies and request factory audit reports covering SMT line capacity, reflow soldering profiles, and humidity-controlled storage for sensitive components. Assess technical competence via code repository reviews (e.g., GitHub integration examples) and demand reference designs demonstrating successful deployment in e-metering, smart shelf labels, or portable IoT devices.

What is the average sampling timeline?

Standard samples take 10–18 days to produce, including PCB fabrication, component placement, and basic firmware loading. Custom configurations requiring modified layouts or deep-sleep optimization extend lead time to 25–35 days. Air shipping adds 5–9 days depending on destination region.

Can suppliers ship globally?

Yes, experienced manufacturers manage international logistics under FOB, CIF, or DDP terms. Confirm export licensing status and ensure compliance with destination regulations regarding radio frequency emissions (e.g., FCC Part 15 in the U.S.). Sea freight is recommended for volumes exceeding 500 kg to reduce per-unit shipping costs by up to 60%.

Do manufacturers provide free samples?

Sample fees are typically charged but may be waived for confirmed bulk orders (usually ≥500 units). Expect to pay 100–150% of unit cost for initial samples, which often includes programming and testing labor. Some suppliers offer discounted evaluation kits with breakout boards and demo firmware.

How to initiate customization requests?

Submit detailed requirements including display size (e.g., 2.9", 4.2"), resolution, grayscale depth, battery voltage range, communication interface (SPI/I2C), and desired sleep-mode current draw. Leading suppliers respond with schematic integration guides, mechanical drawings, and firmware feature matrices within 72 hours. Full turnkey customization—including custom boot screens and OTA architecture—typically requires 4–6 weeks from design approval to first article.