Electric Button Maker

CN

CN

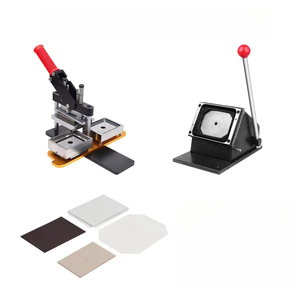

About electric button maker

Where to Find Electric Button Maker Suppliers?

China remains the dominant hub for electric button maker manufacturing, with key production clusters in Guangdong and Zhejiang provinces. Dongguan and Taizhou serve as central nodes in this specialized machinery ecosystem, hosting vertically integrated facilities that combine R&D, precision engineering, and assembly under one roof. These regions benefit from mature supply chains for servo motors, dies, and metal stamping components, enabling cost efficiencies of 20–35% compared to equivalent equipment produced in Europe or North America.

The industrial clusters support rapid prototyping and scalable production, with many suppliers operating automated CNC machining centers and tooling workshops within 10km of final assembly lines. This proximity reduces component lead times by up to 40%, facilitating faster order fulfillment—typically 15–30 days for standard models. Buyers gain access to a diverse product range, from compact semi-automatic units for small-scale DIY operations to fully electric industrial machines capable of 1,000+ cycles per hour.

How to Choose Electric Button Maker Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm machine specifications align with intended applications: diameter compatibility (25mm–63.5mm), power source (AC 220V/50Hz standard), and cycle speed (ranging from 300–1,200 buttons/hour). For high-volume buyers, prioritize suppliers offering CE compliance and electrical safety certifications. Validate performance claims through product test reports or video demonstrations of continuous operation.

Production Infrastructure Assessment

Evaluate supplier capacity using objective benchmarks:

- Minimum factory area exceeding 2,000m² for stable output

- In-house tooling and die-making capabilities to support customization

- Dedicated quality control stations with load and endurance testing

Cross-reference on-time delivery rates (target ≥90%) and response times (ideally ≤3 hours) as indicators of operational efficiency.

Sourcing Risk Mitigation

Utilize secure payment mechanisms such as escrow services for initial transactions. Prioritize suppliers with documented quality management practices and verified export histories. Request physical or digital samples before bulk ordering to assess build quality, press accuracy, and material durability. Confirm packaging standards for international shipping to prevent transit damage.

What Are the Best Electric Button Maker Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Dongguan Ruiyee Machinery Co., Ltd. | Guangdong, CN | US $180,000+ | 100% | ≤2h | <15% | Yes | 1 piece | $3,900–$17,520 |

| Dongguan BanMo Machinery Co., Ltd. | Guangdong, CN | US $370,000+ | 99% | ≤2h | <15% | Yes | 1 unit | $195–$1,000 |

| Taizhou My Button Machine Co., Limited. | Zhejiang, CN | US $40,000+ | 78% | ≤10h | <15% | Limited | 1 piece/set | $3,800–$17,500 |

| Dongguan Chengong Machinery Equipment Co., Ltd. | Guangdong, CN | US $120,000+ | 87% | ≤3h | <15% | Limited | 1 unit | $149–$18,999 |

| Qingdao Laozhang Cap Device Co., Ltd. | Shandong, CN | US $9,000+ | Not reported | ≤2h | <15% | Limited | 1 set | $350–$6,000 |

Performance Analysis

Dongguan-based suppliers dominate responsiveness and reliability, with two achieving sub-2-hour average reply times and on-time delivery rates above 99%. Dongguan Ruiyee and BanMo stand out for strong online revenue performance and customization flexibility, supporting tailored configurations in size, color, and branding. While Taizhou My Button Machine offers similar high-end models, its lower on-time delivery rate (78%) suggests potential fulfillment risks. Cost-effective entry-level machines are available from multiple suppliers, with functional electric button makers priced under $200, though these typically serve low-volume or artisanal use cases. For industrial deployment, prioritize suppliers with proven track records in automation integration and after-sales technical support.

FAQs

How to verify electric button maker supplier credibility?

Validate certifications (CE, ISO) where claimed, and request evidence of product testing under sustained loads. Analyze transaction history, including verified revenue metrics and customer feedback focused on machine uptime and service responsiveness. Conduct virtual audits to confirm in-house manufacturing versus trading activity.

What is the typical lead time for electric button makers?

Standard units ship within 15–20 days after order confirmation. Customized or fully automatic models may require 25–35 days for production and pre-shipment inspection. Air freight delivers in 5–7 days; sea freight takes 20–35 days depending on destination port.

Do suppliers offer customization options?

Yes, select manufacturers provide OEM/ODM services including logo imprinting, color variation, voltage adaptation, and packaging design. Dongguan Ruiyee and BanMo explicitly list graphic, label, and material customization among their offerings.

What are common MOQs for electric button making machines?

Most suppliers allow single-unit orders, particularly for entry-level or semi-automatic models. Bulk pricing typically applies at 5+ units. Industrial-scale automated systems may require full-set purchases with MOQs defined per configuration.

Can electric button makers be integrated into existing production lines?

High-end models from suppliers like Dongguan Chengong and Ruiyee support integration via programmable logic controllers (PLCs) and sensor-based automation. Buyers should confirm I/O interface compatibility and request technical schematics prior to procurement.