Electrical And Electronics Engineer

Top sponsor listing

Top sponsor listing

0

0

0

0

0

0

0

0

1/3

1/3

0

0

1/13

1/13

1/3

1/3

0

0

1/1

1/1

1/1

1/1

1/2

1/2

1/1

1/1

1/1

1/1

0

0

1/1

1/1

1/3

1/3

1/1

1/1

1/1

1/1

About electrical and electronics engineer

Where to Find Electrical and Electronics Components Suppliers?

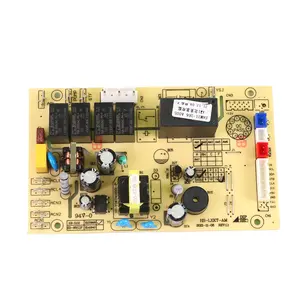

Global manufacturing of electrical and electronics components is concentrated in specialized industrial zones across Asia, with China serving as the dominant hub due to its mature supply chain infrastructure and technical workforce. Key production clusters in Guangdong and Jiangsu provinces host vertically integrated facilities capable of handling full-cycle development—from PCB design and component sourcing to assembly and testing. These regions benefit from proximity to semiconductor foundries, passive component manufacturers, and logistics networks, enabling rapid prototyping and scalable production runs.

The ecosystem supports both high-volume OEMs and low-volume custom engineering projects. Suppliers in these zones typically operate automated SMT lines, in-house testing labs, and conformal coating or potting stations for environmental protection. This integration reduces lead times by 20–30% compared to fragmented supply chains and allows for tighter control over quality and traceability. Buyers gain access to suppliers offering turnkey PCBA services, embedded firmware integration, and compliance testing for international markets.

How to Choose Electrical and Electronics Components Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical & Engineering Capabilities

Prioritize suppliers with demonstrated expertise in PCB assembly (PCBA), including multilayer board fabrication (up to 16 layers), surface mount technology (SMT), and through-hole processes. Verify support for mixed-technology assemblies and design-for-manufacturability (DFM) feedback. For smart devices or IoT applications, confirm experience with wireless modules (Bluetooth, Wi-Fi, Zigbee), power management circuits, and sensor integration.

Quality Assurance Systems

Ensure adherence to recognized standards such as ISO 9001 for quality management and IPC-A-610 for electronic assembly acceptability. For products targeting EU or North American markets, RoHS and REACH compliance is mandatory. Request evidence of incoming material inspection protocols, in-process testing (ICT, AOI, X-ray), and final functional testing procedures.

Production Capacity & Responsiveness

Evaluate based on measurable indicators:

- Minimum factory area exceeding 2,000m² for stable throughput

- In-house engineering teams supporting customization and troubleshooting

- On-time delivery rate ≥95% and average response time ≤3 hours

- Monthly production capacity aligned with order volume (e.g., 50,000+ units)

Cross-reference performance metrics with actual transaction histories where available, particularly for repeat business rates and post-sale support responsiveness.

Customization and Scalability

Confirm capability for end-to-end product development, including schematic capture, PCB layout, component sourcing, and enclosure integration. Assess flexibility in MOQ—leading suppliers often accommodate pilot runs under 100 units while scaling to millions annually. For consumer electronics, verify experience with FCC, CE, or UL certification pathways.

What Are the Best Electrical and Electronics Components Suppliers?

| Company Name | Type | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Support |

|---|---|---|---|---|---|---|---|

| Zhongshan Huishine Pcba Co., Ltd. | Custom Manufacturer | PCBA, Multilayer PCB, LCD Modules, Pet Interactive Toys, Remote Controls | 100% | ≤2h | <15% | US $220,000+ | Yes – design, assembly, engineering |

| Milian Limited | OEM/ODM Supplier | Smart Home Devices, USB Charging Solutions, Electric Hair Tools, Induction Cookers | 100% | ≤3h | <15% | US $1,000+ | Limited – focused on consumer electronics |

| General Agric Limited Partnership | Distributor | Plastic Granules (HDPE, PP), Raw Materials | - | ≤5h | - | - | No – bulk material supplier only |

| Auto Winters Beheer BV | Distributor | Polypropylene (PP) Granules, Virgin Plastic Pellets | - | ≤1h | - | - | No – raw materials focus |

| J Pilon SA Acucar e Alcool | Raw Material Supplier | Polycarbonate (PC), Modified PC Particles, Polypropylene Granules | - | ≤10h | - | - | No – industrial polymer supplier |

Performance Analysis

Zhongshan Huishine Pcba Co., Ltd. stands out as a dedicated custom manufacturer with verified engineering capabilities in PCB assembly and product-level integration, supported by consistent on-time delivery and responsive communication. Its specialization in interactive toys and remote controls indicates strong competency in low-power electronics and motion control systems. Milian Limited offers competitive entry points for smart home and personal care electronics, though lower online revenue suggests smaller-scale operations.

The remaining three suppliers primarily deal in raw plastic materials—HDPE, PP, and PC granules—used in housing and structural components for electronic devices. While logistically efficient, they do not provide electronic design or assembly services. Buyers seeking full product realization should prioritize manufacturers like Zhongshan Huishine that offer integrated design, prototyping, and production services backed by measurable performance data.

FAQs

How to verify an electronics supplier’s technical competence?

Request detailed process documentation, including BOM management, solder paste inspection reports, and test jigs used for functional validation. Conduct virtual audits of SMT lines and ask for sample builds with traceable component lot numbers. Confirm use of ESD-safe environments and humidity-controlled storage for moisture-sensitive parts.

What is the typical lead time for custom PCBA orders?

Standard turnaround ranges from 15 to 25 days, including component procurement, assembly, and testing. Expedited services may reduce this to 7–10 days for small batches. Complex multilayer boards or constrained component availability can extend timelines to 35 days.

Do suppliers support small-batch prototyping?

Yes, many manufacturers accept MOQs as low as 1–10 units for initial prototypes. Tooling charges may apply for stencil creation or programming test fixtures. Volume pricing typically begins at 1,000 units.

Are RoHS and REACH compliance certificates available?

Reputable suppliers provide material declarations and compliance documentation upon request. For export-bound goods, ensure conformity with destination-market regulations, including CE marking requirements for EMC and LVD directives.

Can suppliers assist with regulatory certifications?

Experienced partners offer pre-compliance testing for FCC, CE, and CB schemes, often collaborating with third-party labs to accelerate formal certification. Confirm prior experience with similar product classes to avoid delays during market entry.