Emboss Machine Producer

About emboss machine producer

Where to Find Emboss Machine Producers?

China remains the global epicenter for emboss machine manufacturing, with specialized production clusters in Guangdong, Zhejiang, and Jiangsu provinces driving innovation and cost efficiency. Shenzhen and Dongguan in Guangdong province host precision engineering firms focused on small-format embossing systems for plastic cards and leather goods, leveraging proximity to electronics and polymer supply chains. Zhejiang’s Hangzhou and Huzhou regions specialize in heavy-duty industrial embossing lines for metal coils and building materials, supported by integrated steel processing ecosystems that reduce raw material procurement cycles by 20–25%.

These regional hubs enable vertically aligned production networks—spanning mold fabrication, thermal system integration, and CNC machining—within compact geographic zones. Suppliers benefit from rapid prototyping capabilities and localized component sourcing, translating into lead times of 15–30 days for standard units and 45–60 days for customized systems. Buyers gain access to scalable production capacity, with average factory areas exceeding 3,000m² and monthly output ranging from 50 to 200 units depending on machine complexity. Cost advantages are significant, with Chinese producers offering 25–40% lower pricing than European or North American counterparts due to optimized labor and logistics structures.

How to Choose Emboss Machine Producers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Quality Assurance

Verify adherence to international quality standards such as ISO 9001. For export markets, CE marking is essential for electrical safety and regulatory clearance. Request documentation on heating element durability, pressure calibration, and cycle testing—particularly for hot stamping and foil embossing models. Confirm compliance with RoHS directives where applicable, especially for machines handling PVC or synthetic substrates.

Production Capability Assessment

Evaluate core manufacturing infrastructure through the following indicators:

- Minimum facility size of 2,000m² to support dedicated assembly and testing zones

- In-house design and R&D teams capable of custom tooling and die fabrication

- Integration of CNC machining, welding, and thermal system calibration within the same facility

Cross-reference supplier performance metrics: prioritize those with on-time delivery rates ≥97% and response times under 3 hours to ensure operational responsiveness.

Transaction Security & After-Sales Support

Utilize secure payment mechanisms such as escrow services to mitigate risk during initial transactions. Assess after-sales capability through availability of technical manuals, remote diagnostics, and spare parts inventory. Review reorder rates as a proxy for customer satisfaction—producers with rates above 25% typically offer reliable performance and service consistency.

What Are the Best Emboss Machine Producers?

| Company Name | Location | Main Materials | Machine Types | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Customization |

|---|---|---|---|---|---|---|---|---|

| Zhejiang Zhongnuo Intelligent Machinery Co., Ltd. | Zhejiang, CN | Stainless Steel, Metal Sheets | Automatic Metal Plate Embossing Lines | 100% | ≤3h | US $390,000+ | 100% | Yes |

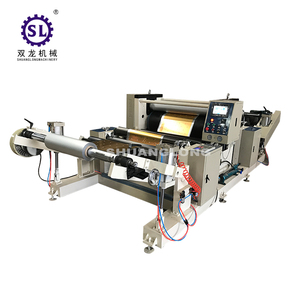

| Changzhou Pinghui Machinery Co., Ltd. | Jiangsu, CN | Metal Coils, Aluminum Foil | Cold Rolling Mill Embossing Systems | 100% | ≤3h | - | - | Limited |

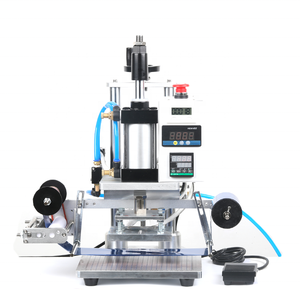

| Dongguan Jinglin Machine Co., Ltd. | Guangdong, CN | Leather, Plastic Films | Manual Hot Stamping & Foil Embossers | 94% | ≤2h | US $80,000+ | 25% | Yes |

| Dongguang Shipai Zhengfei Die Factory | Shandong, CN | Fabric, Leather, Cardstock | Pneumatic & Manual Press Machines | 97% | ≤2h | US $230,000+ | 30% | Yes |

| Shenzhen Mycard Technologies Co., Ltd. | Guangdong, CN | PVC, Plastic Cards | Manual ID Card Embossers | 97% | ≤7h | US $60,000+ | <15% | No |

Performance Analysis

Zhejiang Zhongnuo stands out with a 100% reorder rate and full customization capability, indicating strong client retention and engineering flexibility for industrial-scale metal embossing solutions. Changzhou Pinghui offers high-reliability coil processing systems but lacks public reorder data, suggesting limited repeat transaction visibility. Dongguan Jinglin and Dongguang Shipai Zhengfei demonstrate robust responsiveness (≤2h) and mid-tier reorder rates (25–30%), positioning them as reliable partners for SMEs requiring leather and textile embossing equipment. Shenzhen Mycard focuses on low-cost PVC card embossers with minimal customization and sub-15% reorder activity, indicating niche market positioning with limited scalability. Buyers seeking automated, high-capacity systems should prioritize suppliers with documented experience in turnkey production lines and CE-certified control panels.

FAQs

How to verify emboss machine producer reliability?

Cross-validate certifications (ISO, CE) with issuing bodies and request audit reports covering production workflows and quality control checkpoints. Analyze verified transaction histories, focusing on on-time delivery consistency and post-installation support responsiveness.

What is the typical sampling timeline for emboss machines?

Standard sample production takes 7–14 days for manual models. Automated or custom-configured systems require 25–40 days for prototype completion. Air freight adds 5–10 days for international delivery.

Do emboss machine producers support global shipping?

Yes, most established manufacturers offer FOB and CIF shipping terms with containerized packaging for sea freight. Confirm compatibility with local voltage standards (e.g., 220V/380V) and customs documentation requirements for machinery imports.

Are customization options widely available?

Mid-to-large producers like Zhejiang Zhongnuo and Dongguang Shipai Zhengfei provide full customization—including size, pressure settings, heating elements, and branding—supported by in-house tooling departments. Smaller suppliers may limit modifications to pre-defined configurations.

What are common MOQ and pricing structures?

MOQ is typically 1 unit for standard models, enabling low-volume procurement. Prices range from $80 for basic handheld stamping devices to $76,000 for fully automated stainless steel plate embossing lines. Bulk orders (10+ units) often qualify for 5–15% discounts and extended warranty coverage.