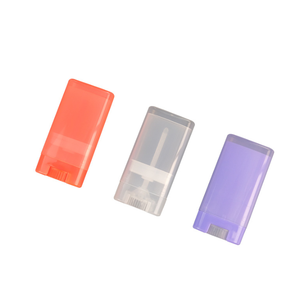

Empty Deodorant Container Stick Producer

CN

CN

About empty deodorant container stick producer

Where to Find Empty Deodorant Container Stick Producers?

China remains the global hub for empty deodorant stick container manufacturing, with key production clusters in Zhejiang, Guangdong, and Henan provinces. These regions host vertically integrated facilities equipped with dedicated injection molding lines, enabling high-volume output of precision cosmetic packaging. Suppliers in Yuyao (Zhejiang) and Dongguan (Guangdong) specialize in plastic-based deodorant sticks using polypropylene (PP), ABS, and PCR materials, leveraging localized polymer supply chains and mature tooling infrastructure.

The industrial ecosystem supports rapid prototyping and scalable production, with many manufacturers operating fully automated assembly lines capable of producing 500,000–2 million units monthly. Proximity to ports such as Ningbo and Shenzhen enables efficient export logistics, reducing transit time for international buyers. Economies of scale allow for competitive pricing, particularly for bulk orders exceeding 10,000 pieces, where per-unit costs can drop below $0.30. Buyers benefit from access to a consolidated network of material suppliers, mold makers, and surface treatment providers within a 50km radius, ensuring shorter lead times and flexible customization options.

How to Choose Empty Deodorant Container Stick Producers?

Procurement decisions should be guided by rigorous supplier evaluation across three core dimensions:

Production & Customization Capabilities

Verify that suppliers operate in-house injection molding and finishing equipment. Key capabilities include color matching (Pantone standards), hot-stamping, silk screening, water transfer printing, and custom mold development. Leading producers offer full OEM/ODM services, including private mold creation, label integration, and matte/gloss finish application. Confirm minimum order quantities (MOQs), which typically range from 5,000 to 10,000 pieces for standard designs and may require higher volumes for custom tooling.

Quality Assurance & Compliance

Prioritize manufacturers with documented quality management systems. While formal ISO 9001 certification is not universally declared in available data, on-time delivery rates above 95% and reorder rates exceeding 25% serve as operational proxies for reliability. Evaluate response times (ideally under 5 hours) and historical performance metrics such as on-time shipment consistency. Materials should comply with RoHS and REACH standards for consumer safety, especially for direct skin-contact products like deodorants.

Transaction Security & Export Readiness

Assess online transaction volume and buyer feedback patterns. Suppliers with verifiable annual revenues exceeding US $1 million demonstrate market validation and logistical maturity. Request product samples to evaluate wall thickness, cap fit, twist mechanism smoothness, and structural integrity under thermal stress. Use secure payment mechanisms and confirm packaging suitability for international shipping. Clarify lead times—typically 15–30 days post-sample approval—and confirm FOB or EXW terms.

What Are the Top Empty Deodorant Container Stick Producers?

| Company Name | Location | Verified Type | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | MOQ Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Zhejiang Chance Packaging Co., Ltd. | Zhejiang, CN | Multispecialty Supplier | 96% | 16% | ≤2h | US $70,000+ | 5,000–10,000 pcs | $0.31–0.75 |

| Choebe (Dongguan) Package Co., Ltd. | Guangdong, CN | Custom Manufacturer | 100% | 27% | ≤5h | US $3,600,000+ | 5,000–10,000 pcs | $0.37–0.87 |

| Yuyao Caiyun Cosmetics Packaging Co.,Ltd. | Zhejiang, CN | Custom Manufacturer | 84% | 30% | ≤7h | US $2,000+ | 10,000 pcs | $0.29–0.44 |

| Zhejiang Magicpack Co., Ltd. | Zhejiang, CN | - | 62% | 33% | ≤4h | US $10,000+ | 1,000–10,000 pcs | $0.26–0.55 |

| Hangzhou Xiaoshan Guocun Plastic Factory | Zhejiang, CN | - | 100% | - | ≤11h | US $1,000+ | 10,000 pcs | $0.30–1.00 |

Performance Analysis

Choebe (Dongguan) Package Co., Ltd. stands out with a 100% on-time delivery rate and the highest reported online revenue (US $3.6M+), indicating strong export capacity and customer satisfaction. Despite a slower response time than peers, its robust customization portfolio—including material, color, size, and logo integration—makes it ideal for branded product development. Zhejiang Magicpack offers the lowest MOQ (1,000 pieces), providing flexibility for startups or small-batch testing, though its 62% on-time delivery rate presents a risk factor requiring closer oversight.

Zhejiang Chance Packaging combines competitive pricing ($0.31/unit at scale) with rapid response times (≤2h), making it suitable for time-sensitive reorders. Yuyao Caiyun delivers cost-effective solutions with prices as low as $0.29/unit, but its lower on-time performance (84%) warrants contingency planning. Hangzhou Xiaoshan Guocun Plastic Factory achieves perfect delivery adherence, yet lacks reorder rate data and operates at higher price variability ($0.30–$1.00), suggesting inconsistent specifications unless tightly controlled.

FAQs

What materials are commonly used in empty deodorant stick containers?

Polypropylene (PP) is the most widely used due to its durability, chemical resistance, and recyclability. Additional materials include ABS for rigid structures, PCR (post-consumer recycled) plastics for sustainability claims, and AS for transparent variants. Material selection impacts wall thickness, thermal stability during filling, and compatibility with gel or solid formulations.

What is the typical lead time for production?

Standard orders take 15–25 days after sample confirmation. Custom molds add 7–14 days for design and fabrication. Expedited production may be available for stock configurations, depending on factory workload and component availability.

Can suppliers provide free samples?

Most suppliers offer samples for evaluation, though buyers typically cover shipping costs. Fees may apply for custom prototypes involving new molds or finishes. Sample requests should specify capacity, color, closure type, and surface treatment to ensure accurate representation.

What customization options are available?

Manufacturers support extensive customization: capacity (15ml–75ml), color (custom Pantone matching), labeling (silk screen, hot-stamp, water transfer), cap design, texture (matte, frosted, glossy), and private labeling. Some offer refillable mechanisms and eco-friendly packaging configurations.

How do I verify production quality before mass order?

Request physical or digital (video) factory audits to assess injection molding lines, quality control stations, and packaging processes. Conduct sample testing for dimensional accuracy, torque resistance of twist mechanisms, leak-proof seals, and compatibility with intended formulations. Third-party inspection services can validate batches pre-shipment.