Example Of Evaluation Of Suppliers

CN

CN

CN

CN

CN

CN

About example of evaluation of suppliers

Where to Find Supplier Evaluation Service Providers?

China remains a central hub for professional supplier evaluation and sourcing services, with specialized providers concentrated in key industrial and logistics centers such as Nanjing, Yiwu, and Guangzhou. These regions host firms offering end-to-end assessment solutions, including factory audits, quality control inspections, and vendor compliance verification. Nanjing and surrounding Jiangsu province are emerging as focal points for certification and inspection agencies due to proximity to major export ports and a high concentration of accredited technical auditors.

Yiwu and Guangzhou serve as critical nodes for integrated sourcing and market-based supplier assessments, particularly for light consumer goods. These cities support extensive purchasing agent networks that combine on-ground verification with digital supply chain tools. The ecosystem enables rapid sample acquisition, real-time production monitoring, and consolidated shipment management. Buyers benefit from localized expertise across diverse product categories—from textiles to electronics—supported by mature logistics infrastructure and multilingual service teams.

How to Choose Supplier Evaluation Service Providers?

Selecting a reliable partner requires rigorous assessment across three core dimensions:

Verification Methodology

Prioritize providers that conduct on-site factory audits with documented checklists covering production capacity, equipment condition, workforce size, and quality management systems. Services should include photographic evidence, process flow analysis, and compliance validation against international standards such as ISO 9001 or IATF 16949 where applicable. Remote desktop audits may supplement but not replace physical inspections for high-risk procurements.

Service Scope and Technical Coverage

Evaluate the breadth of inspection offerings:

- Pre-production audits to assess raw material sourcing and tooling readiness

- In-process quality checks during manufacturing runs

- Pre-shipment inspections (PSI) with AQL sampling (typically Level II, Acceptable Quality Limit 2.5)

- Container loading supervision and packaging integrity reviews

Confirm whether the provider supports industry-specific testing—for example, electrical safety for electronics or composition analysis for food-contact materials.

Operational Performance Metrics

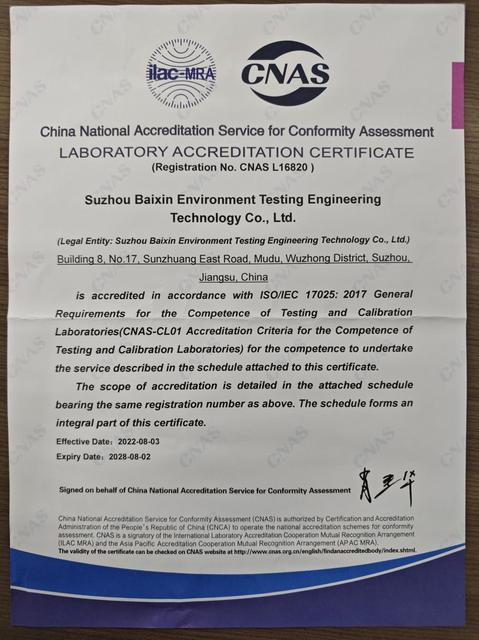

Analyze verifiable performance data: target suppliers with on-time delivery rates exceeding 98%, average response times under 24 hours, and documented reorder rates indicating client retention. High online transaction volumes may reflect consistent service execution and scalability. For regulated industries, confirm availability of third-party accreditation (e.g., CNAS, ILAC) to ensure report validity in international markets.

What Are the Leading Supplier Evaluation Service Providers?

| Company Name | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Nanjing Marsky Inspection Certification Co., Ltd. | Inspection & Quality Control Services | 100% | ≤4h | 21% | US $20,000+ | 1 case | $135–200 |

| Yiwu Sunshine Trade Co., Ltd. | Yiwu Purchasing Agent, Apparel, Socks | 100% | ≤2h | 18% | US $5,400,000+ | 1–2 cases | $199–333 |

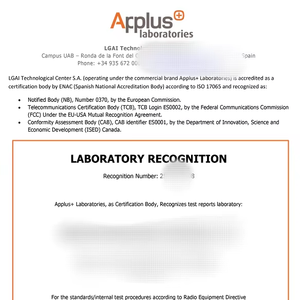

| Applus China Co., Ltd. | Quality Control, Pre-Shipment Inspection | 100% | ≤9h | - | - | 1 unit | $1–847.20 |

| Market Union Co., Ltd. | Supplier Search, Educational Toys | 100% | ≤4h | - | - | 10 bags/pieces | $0.49–2.30 |

| MEKONG DELTA IMPORT EXPORT COMPANY LIMITED | Bamboo Crafts, Silk Scarves, Clothing Sets | - | ≤23h | - | - | 1000 pieces | $3 |

Performance Analysis

Nanjing Marsky and Applus China represent dedicated inspection specialists with standardized audit protocols suitable for regulated sectors. Both offer structured pricing per inspection case, ensuring cost predictability. Yiwu Sunshine Trade demonstrates high operational volume and responsiveness, reflecting deep integration within Yiwu’s wholesale ecosystem—ideal for buyers managing frequent small-batch orders across apparel and accessories. Market Union provides low-cost supplier search packages, enabling scalable vetting for commodity items. MEKONG DELTA focuses on product-specific sourcing rather than pure evaluation services, with higher MOQs aligned with finished goods procurement. Firms with response times under 4 hours—Nanjing Marsky, Yiwu Sunshine, and Market Union—offer competitive advantages for time-sensitive sourcing cycles.

FAQs

How to verify the credibility of a supplier evaluation service?

Cross-check issued audit reports with independent databases or accreditation bodies such as CNAS or ABIS. Request redacted sample reports to evaluate depth of documentation, including facility photos, machine lists, and labor verification. Validate field auditor qualifications through professional certifications (e.g., CQA, ASQ).

What is the typical lead time for a supplier audit?

Domestic Chinese factory audits can be scheduled within 3–7 business days after request. On-site inspection completion typically takes 1–2 days depending on facility size. Full audit reports with findings and recommendations are delivered within 3–5 working days post-inspection.

Do supplier evaluation services cover international factories?

Some providers extend services beyond China to Vietnam, India, Turkey, and other manufacturing regions. Confirm geographic coverage and local partner network strength before engagement. Additional fees apply for cross-border travel and logistics coordination.

Are samples included in supplier evaluation packages?

Many providers bundle sample collection and quality testing within comprehensive sourcing packages. Clarify whether sample costs, shipping, and lab testing are billed separately. AQL-based sampling is standard for batch validation.

Can these services support customization and OEM procurement?

Yes, leading providers assist in evaluating a manufacturer’s capability to handle custom designs, tooling development, and intellectual property protection. Assess suppliers for mold-making facilities, R&D staffing, and experience with private-label production in your target category.