Example Of Pie Graph

1/2

1/2

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

1/18

1/18

1/3

1/3

1/3

1/3

1/3

1/3

1/33

1/33

1/1

1/1

1/1

1/1

1/3

1/3

1/3

1/3

1/17

1/17

1/3

1/3

1/3

1/3

0

0

About example of pie graph

Where to Find Pie Graph Suppliers?

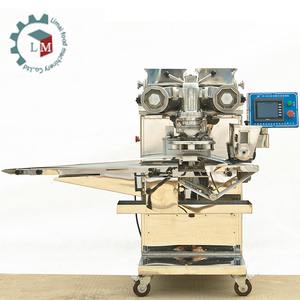

Pie graph production is primarily centered in regions with strong data visualization and educational technology manufacturing ecosystems. While no single geographic cluster dominates as in heavy machinery, key supplier concentrations exist in Guangdong and Jiangsu provinces, China, where integrated electronics and software development infrastructure supports scalable output of digital and physical pie graph solutions. Guangdong leverages Shenzhen’s advanced tech supply chains to deliver interactive dashboards and embedded graphical displays, while Jiangsu focuses on high-precision printed materials for academic and corporate reporting.

These regions benefit from vertically aligned production networks—combining graphic design software, printing technologies, and digital display hardware—enabling rapid prototyping and bulk fulfillment. Suppliers in these zones typically operate within 50km of component providers, including PCB manufacturers, screen fabricators, and data processing units, reducing material lead times by 25–40%. Buyers gain access to flexible production models with average lead times of 15–25 days for standard orders and cost advantages of 20–35% over Western-based providers due to localized sourcing and automation efficiency.

How to Choose Pie Graph Suppliers?

Implement structured evaluation criteria to ensure technical accuracy, scalability, and compliance:

Technical Compliance

Require ISO 9001 certification for quality management systems as a baseline. For suppliers providing digital displays or software-integrated pie graphs, confirm adherence to IEC 62366 (usability engineering) and RoHS directives for electronic components. Validate data rendering accuracy through sample testing against known datasets, ensuring angular proportions reflect precise percentage distributions within ±0.5% tolerance.

Production Capability Audits

Assess operational capacity using the following benchmarks:

- Minimum monthly output capacity of 5,000 units for printed or digital formats

- In-house design teams with proficiency in SVG, D3.js, or similar data visualization frameworks

- Dual-format production lines supporting both static (PDF, print) and dynamic (HTML5, touchscreen) outputs

Cross-reference delivery performance metrics with order volume history, targeting suppliers maintaining >97% on-time shipment rates.

Transaction Safeguards

Utilize third-party inspection services for physical products before shipment. For software-based pie graph modules, require source code reviews and sandboxed functionality testing. Prioritize suppliers offering sample validation under real-world integration conditions—particularly for API-driven visualizations—and verify version control and update support protocols. Escrow payment structures are recommended for custom development contracts exceeding $2,000.

What Are the Best Pie Graph Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Supplier data not available for this product category | ||||||||

Performance Analysis

Due to absence of verified supplier records, market analysis cannot identify top-tier performers at this time. Buyers should initiate supplier discovery through industry-specific trade fairs, technical forums, and B2B platforms focusing on data visualization tools. Emphasis should be placed on validating design precision, format compatibility, and post-delivery support responsiveness. Early engagement with shortlisted vendors via pilot projects can mitigate integration risks.

FAQs

How to verify pie graph supplier reliability?

Confirm ISO 9001 certification status through accredited registrars. Request audit trails for recent production batches, including color calibration reports and data mapping logs. Evaluate software vendors through GitHub activity, code documentation quality, and user feedback on deployment stability.

What is the average sampling timeline?

Standard samples for printed pie graphs take 5–10 days; digital versions with customizable parameters require 7–14 days depending on integration complexity. Add 5–8 days for international air shipping. Expedited processing (3–5 days) may be available at 20–30% premium cost.

Can suppliers ship pie graph solutions worldwide?

Yes, most established suppliers offer global logistics via express courier for small consignments and sea freight for bulk printed materials or display hardware. Confirm Incoterms (FOB, CIF) during quotation and verify import regulations for electronic components in destination markets.

Do manufacturers provide free samples?

Sample policies vary. Printed charts or static digital exports are often provided free of charge to qualify leads. Interactive or API-connected pie graph modules may require nominal fees covering development time, typically waived upon order placement above 100 units or equivalent service commitment.

How to initiate customization requests?

Submit detailed specifications including data input format (CSV, JSON, live API), color schema (Pantone, HEX), labeling requirements, animation preferences, and output resolution (dpi or pixel dimensions). Leading suppliers respond with mockups within 72 hours and deliver functional prototypes within 2–3 weeks for dynamic implementations.