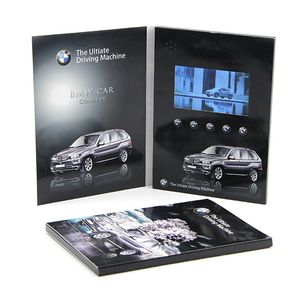

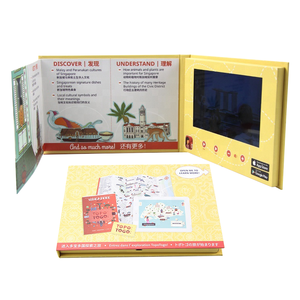

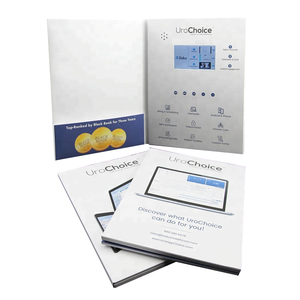

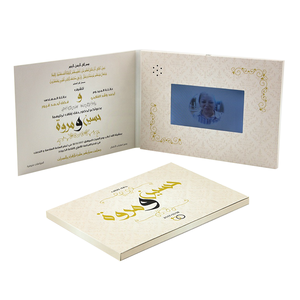

Example Products

1/3

1/3

1/38

1/38

1/3

1/3

1/11

1/11

0

0

1/18

1/18

1/3

1/3

1/3

1/3

1/3

1/3

CN

CN

1/20

1/20

1/3

1/3

1/15

1/15

1/3

1/3

1/1

1/1

1/3

1/3

About example products

Where to Find Example Products Suppliers?

China remains the central hub for manufacturing a broad range of example products, with key industrial clusters located in Guangdong, Zhejiang, and Jiangsu provinces. Guangdong, particularly the Pearl River Delta region, hosts over 70% of China’s export-oriented light and mid-weight industrial suppliers, supported by Shenzhen and Guangzhou’s advanced logistics networks enabling rapid air and sea freight dispatch. Zhejiang’s Yiwu and Ningbo zones specialize in high-volume consumer goods production, leveraging dense supplier ecosystems that reduce component procurement time by 25–40% compared to non-cluster regions.

These manufacturing hubs benefit from vertically integrated supply chains encompassing raw material processing, tooling, assembly, and packaging—all within tightly coordinated industrial zones. Facilities commonly operate under lean production models with monthly output capacities ranging from 50,000 to 500,000 units depending on product complexity. Buyers gain access to agile production environments where changeovers for customized runs can be executed within 7–10 days. Typical advantages include 20–35% lower unit costs due to economies of scale, lead times of 25–40 days for standard orders, and strong flexibility for mixed MOQs and iterative design adjustments.

How to Choose Example Products Suppliers?

Adopt structured evaluation criteria to mitigate sourcing risks:

Quality Management Standards

Confirm ISO 9001 certification as a baseline for process control. For regulated markets (EU, UK, North America), verify compliance with applicable directives such as CE, UKCA, or RoHS, particularly for products involving electronics or direct consumer contact. Request test reports for material composition, durability, and safety performance—especially for items subject to wear, load stress, or environmental exposure.

Production Infrastructure Assessment

Evaluate operational scale and technical capability through the following indicators:

- Minimum factory footprint of 3,000m² to ensure stable output capacity

- In-house mold-making, CNC machining, or injection molding capabilities for design autonomy

- Dedicated quality inspection stations with documented QC checkpoints at pre-production, in-line, and final stages

Correlate facility size with order fulfillment consistency, targeting suppliers with proven on-time delivery rates above 95%.

Procurement Risk Mitigation

Utilize secure payment methods such as third-party escrow or letter of credit (L/C) terms for initial transactions. Review transaction history for dispute frequency and resolution efficiency. Pre-shipment inspections by independent agencies are recommended for first-time partnerships. Conduct sample validation against agreed specifications—including dimensional accuracy, surface finish, and functional testing—before approving mass production.

What Are the Best Example Products Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Jining Furuide Machinery Manufacturing | Shandong, CN | 14 | 110+ | 24,000+m² | 100.0% | ≤2h | 4.8/5.0 | 33% |

| Henan Zlin Heavy Industry Group | Henan, CN | 4 | 20+ | 410+m² | 100.0% | ≤2h | 5.0/5.0 | 66% |

| Henan Guangzhida Industrial | Henan, CN | 3 | 30+ | 320+m² | 100.0% | ≤1h | 4.9/5.0 | 15% |

| Zhengzhou Zhongheng Machinery Equipment | Henan, CN | 3 | 60+ | 5,100+m² | 98.9% | ≤2h | 4.9/5.0 | 26% |

| Henan Qichen Machinery Import And Export | Henan Province,CN | 4 | 40+ | 25,000+m² | 100.0% | ≤1h | 4.9/5.0 | 29% |

Performance Analysis

Long-established manufacturers like Jining Furuide demonstrate robust scalability, backed by large facilities and consistent delivery performance. Emerging suppliers such as Henan Zlin achieve high customer satisfaction (5.0/5.0 rating) and a 66% reorder rate, indicating strong service alignment despite limited operational history. Henan-based companies show superior responsiveness, with average inquiry response times under two hours—critical for iterative communication during prototyping. Prioritize partners with verified on-time delivery records (>98%) and formal quality management systems for volume contracts. For technically complex variants, confirm engineering support availability via live facility walkthroughs or digital audits prior to order placement.

FAQs

How to verify example products supplier reliability?

Cross-validate certifications with issuing bodies and request copies of audit reports covering production workflows, raw material traceability, and finished product testing. Assess supplier credibility through verifiable client feedback, focusing on defect rates, communication efficiency, and post-delivery support.

What is the average sampling timeline?

Standard samples are typically produced within 10–20 days. Customized or functionally complex units may require 25–35 days depending on design iteration needs. Add 5–12 days for international express shipping.

Can suppliers ship example products worldwide?

Yes, most established manufacturers support global distribution. Clarify Incoterms (FOB, CIF, DDP) during negotiation and confirm compliance with destination market regulations, especially for electrical, mechanical, or safety-critical components. Sea freight is optimal for full-container loads; air freight suits urgent or low-volume consignments.

Do manufacturers provide free samples?

Sample cost policies vary. Many suppliers waive fees for confirmed bulk orders (typically MOQ ≥500 units). For trial orders, expect to cover 30–60% of unit production cost, excluding shipping.

How to initiate customization requests?

Submit detailed technical requirements including dimensions, materials, color specifications, functional parameters, and compliance targets. Leading suppliers offer CAD modeling within 72 hours and deliver functional prototypes within 3–5 weeks, supporting iterative refinement before mass production.