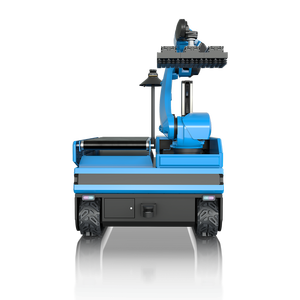

Factory Automation Robots

Top sponsor listing

Top sponsor listing

About factory automation robots

Where to Find Factory Automation Robots Suppliers?

China remains the global epicenter for factory automation robotics manufacturing, with concentrated supplier clusters in Shanghai, Shenzhen, Beijing, and Shandong province offering distinct regional advantages. These hubs feature vertically integrated supply chains, advanced R&D capabilities, and proximity to Tier-1 industrial zones across electronics, automotive, and logistics sectors. Shenzhen and Shanghai lead in collaborative robot (cobot) innovation, while Shandong specializes in heavy-duty articulated robotic arms and automated packaging systems.

The industrial ecosystems support rapid prototyping and scalable production, enabling suppliers to fulfill both small-batch customization and high-volume orders efficiently. Key benefits include localized access to servo motors, controllers, and structural components—reducing material lead times by 20–35%. Buyers can expect average production cycles of 30–45 days for standard units, with cost advantages of 25–40% compared to Western or Japanese manufacturers due to lower labor and operational overheads.

How to Choose Factory Automation Robots Suppliers?

Procurement decisions should be guided by systematic evaluation of technical, operational, and transactional performance indicators:

Technical & Functional Compliance

Verify product specifications align with application requirements—payload capacity (1kg–30kg), degrees of freedom (6-axis standard), repeatability (±0.02mm typical), and integration compatibility (PLC, HMI, IoT protocols). Demand compliance with international safety standards such as CE, ISO 10218 (industrial robots), and ISO/TS 15066 (collaborative robots) for deployment in regulated environments.

Production & Engineering Capability

Assess core competencies through the following criteria:

- In-house design and assembly facilities covering robotic arms, control systems, and end-effectors

- Demonstrated expertise in key automation segments: cobots, palletizing, material handling, welding, or delivery robotics

- Customization options for speed, reach, mounting configuration, and communication interfaces

Cross-reference product listing diversity with response time and reorder rate data to gauge operational responsiveness and customer retention.

Supply Chain Reliability & Transaction Security

Prioritize suppliers with verifiable on-time delivery records (target ≥95%) and structured after-sales support. Utilize digital procurement platforms to validate online revenue trends and order fulfillment history. For initial engagement, request functional prototypes or video demonstrations of live operation. Employ secure payment mechanisms with milestone-based releases tied to shipment and commissioning milestones.

What Are the Best Factory Automation Robots Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization |

|---|---|---|---|---|---|---|---|

| Senad Robot(Shanghai) Co., Ltd. | Shanghai, CN | Conveyors (342), Manipulator (77) | 100% | 100% | ≤5h | US $120,000+ | Yes |

| Shenzhen Era Automation Co., Ltd. | Shenzhen, CN | Collaborative Robots (161), AGV (3) | 100% | 25% | ≤2h | US $350,000+ | Yes |

| Beijing LJ Robot Technology Co., Ltd. | Beijing, CN | Commercial Delivery Robots (139) | 50% | 50% | ≤1h | US $10,000+ | Limited |

| Bremetz (Shandong) Machinery Co., Ltd. | Shandong, CN | Articulated Robots (73), Packaging Lines (145) | 100% | - | ≤3h | - | Yes |

| Xiamen Device Technology Co., Ltd. | Xiamen, CN | Other Industrial Robots (355), Articulated Robots (168) | - | 100% | ≤3h | - | Yes |

Performance Analysis

Senad Robot and Shenzhen Era Automation demonstrate strong reliability with 100% on-time delivery and robust online sales volume, indicating stable production capacity. Shenzhen Era stands out for its focus on collaborative robots and rapid ≤2-hour response times, ideal for buyers requiring agile technical support. Xiamen Device Technology shows high customer loyalty (100% reorder rate), suggesting consistent product quality despite limited public performance metrics.

Bremetz (Shandong) offers diversified automation solutions including integrated packaging lines, making it suitable for turnkey system integrators. In contrast, Beijing LJ Robot focuses on commercial delivery automation with moderate delivery reliability (50%), warranting additional scrutiny for mission-critical deployments. Buyers seeking customization should prioritize suppliers explicitly listing configurable parameters such as color, control interface, or motion specifications.

FAQs

How to verify factory automation robot supplier credibility?

Validate certifications (CE, ISO) through official registries and request test reports for motor endurance, positioning accuracy, and electrical safety. Conduct virtual audits via facility walkthrough videos and assess software integration documentation. Analyze historical transaction data, focusing on dispute resolution outcomes and post-sale service responsiveness.

What is the typical MOQ and pricing range?

Most suppliers list a minimum order quantity of 1 set, with prices ranging from $1,399 for compact cobots to over $24,000 for high-payload industrial models. Unit pricing often decreases marginally for orders exceeding five units, particularly for standardized configurations.

Are customization options widely available?

Yes, many suppliers offer modifications in payload, arm length, mounting style, and control panel layout. Some provide OEM branding and software SDK access for seamless integration into existing production networks. Confirm feasibility through engineering consultations before finalizing contracts.

What are common lead times for production and shipping?

Standard units typically ship within 30 days after order confirmation. Customized systems may require 45–60 days depending on complexity. Air freight delivers in 7–10 days internationally; sea freight takes 25–35 days but reduces transport costs by up to 60% for full-container loads.

Do suppliers support global logistics and after-sales service?

Established exporters offer FOB and CIF shipping terms with assistance in customs clearance documentation. Post-delivery support varies—confirm availability of remote diagnostics, spare parts inventory, and local technical partners in your region prior to purchase.