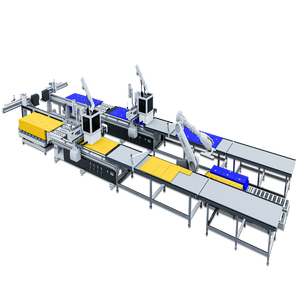

Factory Automation Solutions

About factory automation solutions

Where to Find Factory Automation Solutions Suppliers?

China remains the global epicenter for factory automation solutions, with specialized manufacturing clusters concentrated in Guangdong, Zhejiang, and Henan provinces. These regions host vertically integrated facilities capable of delivering turnkey systems—from custom assembly lines to Industry 4.0-ready production cells. Dongguan and Shenzhen in Guangdong province lead in electronics-focused automation, offering precision machinery for semiconductor, consumer electronics, and smart device manufacturing. Zhejiang excels in HVAC and automotive component automation, while Henan has emerged as a hub for heavy industrial applications, including battery and vehicle production lines.

The concentration of suppliers in these zones enables access to mature ecosystems comprising component manufacturers, robotics integrators, and logistics providers within tight geographic radii. This integration reduces system design-to-deployment timelines by 20–35% compared to decentralized sourcing models. Buyers benefit from scalable production infrastructure, localized engineering talent pools, and streamlined export channels, with average lead times ranging from 45 to 90 days depending on customization complexity.

How to Choose Factory Automation Solutions Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capability

Verify that suppliers adhere to international quality standards such as ISO 9001 and CE marking, particularly for clients in Europe or North America. For safety-critical applications (e.g., automotive or energy storage), confirm compliance with IEC 61508 (functional safety) and RoHS directives. Request detailed documentation of control system architectures, including PLC brands (Siemens, Mitsubishi, Allen-Bradley), HMI interfaces, and SCADA integration capabilities.

Production Infrastructure Assessment

Evaluate core manufacturing competencies through the following criteria:

- Minimum factory area exceeding 3,000m² to support full-line assembly

- In-house engineering teams specializing in robotic integration, vision systems, and MES connectivity

- Proven experience in building complete production lines (not just individual machines)

- On-time delivery performance ≥97%, validated through verifiable transaction records

Cross-reference supplier claims with response time metrics—top-tier vendors typically reply within 4 hours—and prioritize those offering virtual or physical facility audits prior to contract finalization.

Transaction Security & Quality Assurance

Utilize secure payment mechanisms such as escrow services to mitigate risk during large capital equipment procurement. Require sample validation or pilot line deployment before full-scale ordering. Confirm post-installation support structures, including remote diagnostics, technician training, and spare parts availability. Review after-sales service level agreements (SLAs) covering mean time to repair (MTTR) and uptime guarantees.

What Are the Best Factory Automation Solutions Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Verified |

|---|---|---|---|---|---|---|---|---|

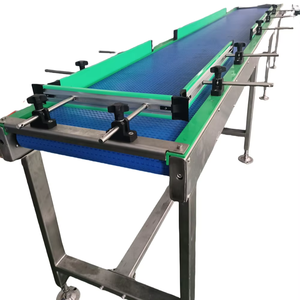

| Dongguan Yicheng Automation Equipment Co., Ltd. | Guangdong, CN | Electronics Production Machinery, Assembly Line | $50K–120K | 1 set/acre | 100% | ≤6h | - | No |

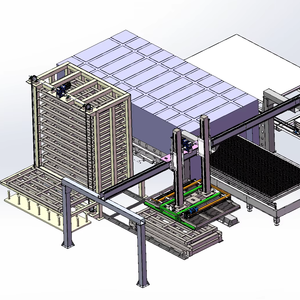

| Zhejiang Yabo Automation Equipment Co., Ltd. | Zhejiang, CN | Vehicle & Air Conditioner Production Lines | $50K–500K | 1 set | 100% | ≤3h | - | No |

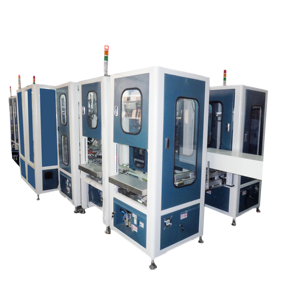

| Shenzhen Tianluo Automation Equipment Co., Ltd. | Guangdong, CN | Electronic Assembly, Packaging, Mask Making | $10K–50K | 1 set | 100% | ≤4h | 100% | Yes (US$2,000+) |

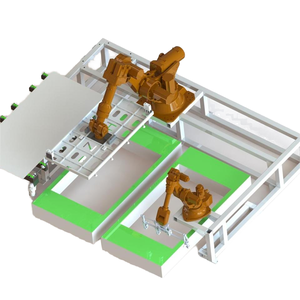

| Zhengzhou Duoyuan Intelligent Equipment Co., Ltd. | Henan, CN | Battery & Automotive Assembly Lines | $45K–156.5K | 1 set | 100% | ≤8h | - | No |

| Hunan Junjiesheng Automation Equipment Co., Ltd. | Hunan, CN | Speaker & Electronics Assembly Lines | $180K–251K | 1 set | 100% | ≤2h | - | No |

Performance Analysis

Hunan Junjiesheng stands out for high-value automation systems, with quoted prices exceeding $180,000 per line, indicating specialization in complex, fully integrated speaker and audio equipment manufacturing. Zhejiang Yabo offers broad scalability, supporting orders up to $500,000, ideal for large-volume HVAC producers. Shenzhen Tianluo demonstrates strong customer retention (100% reorder rate), suggesting consistent quality and responsive service despite lower price points. Dongguan Yicheng and Zhengzhou Duoyuan focus on mid-to-heavy industrial applications, with offerings tied to acre-based installations—indicative of full factory layout projects rather than modular units. All five suppliers maintain perfect on-time delivery records, underscoring reliability in fulfillment, though only Shenzhen Tianluo reports verified online revenue, providing additional transparency.

FAQs

How to verify factory automation supplier credibility?

Validate certifications (ISO, CE) through official registries. Request project references, especially for turnkey line installations. Conduct video audits of production floors and testing bays. Analyze machine commissioning reports and PLC program documentation to assess technical depth.

What is the typical lead time for customized automation lines?

Standard delivery ranges from 60 to 90 days post-design approval. Simpler systems (e.g., single-function stacking machines) may ship in 45 days. Complex, multi-station lines with robotic integration and MES connectivity require 100+ days for fabrication, testing, and FAT (Factory Acceptance Testing).

Do suppliers support global shipping and installation?

Most established suppliers offer FOB or CIF shipping terms and coordinate sea freight logistics. Many provide optional on-site installation and training services at additional cost. Confirm if engineers are available for SAT (Site Acceptance Testing) and whether import documentation (e.g., CE certificates, electrical schematics) is included.

What are common MOQ and pricing structures?

Minimum order quantity is typically one complete system or production cell, priced between $10,000 and $500,000 depending on scope. Pricing reflects automation level, robot density, control system sophistication, and material handling integration. Land-based quotations (e.g., “per acre”) indicate site-wide deployment projects.

How does customization work for automation solutions?

Buyers should submit process flow diagrams, cycle time requirements, product dimensions, and throughput targets. Reputable suppliers respond with conceptual layouts, 3D simulations, and bill-of-materials within 5–7 business days. Prototyping or modular testing is often available for critical stations prior to full-line construction.