Factory Automation Technology

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About factory automation technology

Where to Find Factory Automation Technology Suppliers?

China remains the global epicenter for factory automation technology manufacturing, with key industrial hubs concentrated in Guangdong, Henan, and Jiangsu provinces. These regions host vertically integrated supply chains that combine precision engineering, electronics assembly, and mechanical fabrication under one ecosystem. Guangdong’s Shenzhen zone specializes in intelligent control systems and SMT automation lines, leveraging proximity to semiconductor and PCB production facilities. Meanwhile, Henan and Jiangsu excel in heavy industrial automation, including automotive and tire production lines, supported by robust metalworking infrastructure and cost-efficient logistics networks.

The clustering of component suppliers, R&D centers, and final assembly plants within 50km radii enables rapid prototyping and scalable deployment. Buyers benefit from reduced lead times—typically 45–60 days for customized turnkey systems—and 20–30% lower total system costs compared to equivalent Western-built solutions. This efficiency is further amplified by widespread adoption of Industry 4.0 design principles, modular architectures, and standardized communication protocols across supplier offerings.

How to Choose Factory Automation Technology Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & System Integration

Verify adherence to international standards such as ISO 9001 for quality management and CE marking for electrical safety compliance. For electronics-focused automation (e.g., SMT or PCB lines), confirm compatibility with IPC-A-610 and IEC 60204-1 standards. Request detailed schematics, PLC programming documentation, and HMI interface samples to assess integration readiness with existing factory systems.

Production Capability Verification

Assess core manufacturing competencies through the following criteria:

- Ownership of end-to-end production lines (design, machining, assembly, testing)

- In-house engineering teams capable of customizing workflows, material handling, and machine vision integration

- Minimum facility size of 3,000m² to support large-scale system integration

- On-time delivery performance exceeding 95%, validated through verifiable transaction records

Cross-reference supplier claims with available response time metrics and reorder rates to gauge customer satisfaction and service reliability.

Transaction Safeguards & Procurement Protocols

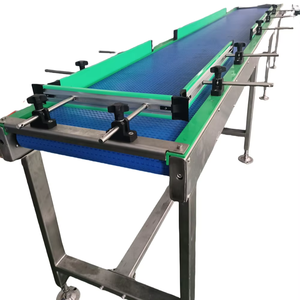

Utilize secure payment mechanisms such as third-party escrow services until site commissioning is confirmed. Prioritize suppliers offering pre-shipment inspection rights and post-installation technical support. Conduct virtual or on-site audits to verify factory capabilities before order placement. Prototype validation is critical—require functional demonstrations of key processes like robotic pick-and-place, conveyor synchronization, or automated quality inspection prior to full deployment.

What Are the Best Factory Automation Technology Suppliers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Tier | Product Range Size |

|---|---|---|---|---|---|---|---|

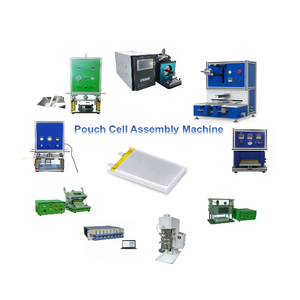

| Xiamen Tmax Battery Equipments Limited | Grinding Equipment, Laboratory Heating, Metal Coating Machinery | Color, material, size, logo, packaging, graphics | 91% | ≤5h | <15% | US $110,000+ | 1,549+ listings |

| Changzhou Hejin Yue International Trade Co., Ltd. | Industrial Chain, Automated Production Lines | Full line customization | 100% | ≤5h | - | Not disclosed | 69 listings |

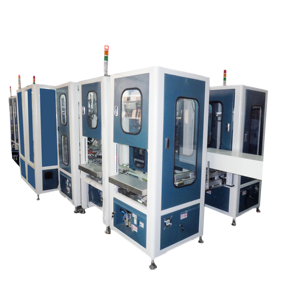

| Zhengzhou Duoyuan Intelligent Equipment Co., Ltd. | Automotive, Circuit Breaker, Bus Assembly Lines | Design and configuration | 100% | ≤9h | - | Not disclosed | 663+ listings |

| Shenzhen Tianluo Automation Equipment Co., Ltd. | Electronic Products Machinery, O-Ring Assembly, Robotics | Custom engineering, robot integration | 100% | ≤5h | 100% | US $2,000+ | 517+ listings |

| Shenzhen Sun Young Intelligent Manufacturing Equipment Co., Limited | SMT, PCB, LED Production Lines | Non-standard design capability | 100% | ≤2h | - | US $900+ | 144+ listings |

Performance Analysis

Suppliers like Zhengzhou Duoyuan and Shenzhen Tianluo demonstrate strong specialization in high-value sectors such as automotive and electronics automation. All top-tier suppliers maintain a 100% on-time delivery rate except Xiamen Tmax, which reports 91%. Notably, Shenzhen Sun Young leads in responsiveness (≤2h average), while Shenzhen Tianluo stands out with a verified 100% reorder rate, indicating exceptional client retention and system reliability. Changzhou Hejin Yue and Zhengzhou Duoyuan focus heavily on industrial assembly lines, whereas Shenzhen-based firms dominate electronic manufacturing automation with advanced SMT and PCB handling systems.

FAQs

How to verify factory automation technology supplier reliability?

Cross-check claimed certifications (ISO, CE) with official databases. Request evidence of past installations, including videos of running production lines and references from overseas clients. Analyze response consistency and technical depth in communications to assess engineering support capacity.

What is the typical lead time for customized automation systems?

Standard configurations require 30–45 days. Fully customized turnkey lines (e.g., automotive body shops or SMT plants) typically take 45–75 days, depending on complexity and component availability. Add 10–15 days for international shipping via sea freight.

Can suppliers accommodate low-volume or prototype orders?

Yes, most suppliers accept single-unit or small-batch orders, especially for pilot lines. Minimum order quantities start at 1 set or 1 square meter for modular conveyors. However, unit costs are higher at low volumes due to fixed engineering overheads.

Do suppliers offer after-sales installation and training?

Reputable manufacturers provide remote debugging support and on-site commissioning services. Some include basic training for operators and maintenance staff. Advanced process optimization or PLC reprogramming may incur additional fees.

How extensive is customization in factory automation systems?

Suppliers commonly offer modifications in layout, speed, load capacity, control interfaces, and integration with MES/SCADA systems. Full custom designs include tailored robotics integration, vision inspection modules, and IoT-enabled monitoring platforms, often delivered with 3D simulations within 72 hours of inquiry.