Factory Automation

CN

CN

Top sponsor listing

Top sponsor listing

1/18

1/18

1/4

1/4

1/18

1/18

CN

CN

1/10

1/10

CN

CN

1/16

1/16

1/30

1/30

1/22

1/22

1/13

1/13

1/12

1/12

About factory automation

Where to Find Factory Automation Suppliers?

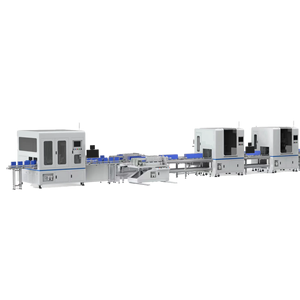

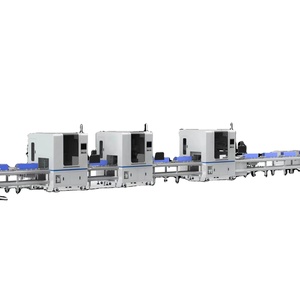

China remains the global epicenter for factory automation equipment manufacturing, with key industrial hubs in Guangdong and Shandong provinces driving innovation and scale. Guangdong’s Pearl River Delta region hosts a dense network of intelligent manufacturing specialists, offering integrated solutions for battery, electronics, and home appliance production lines. Shandong’s Jinan and Qingdao clusters focus on laser-based automation systems and heavy-duty assembly lines, supported by regional steel and mechanical engineering infrastructure that reduces component sourcing lead times by 20–25%.

These regions feature vertically integrated supply ecosystems where automation suppliers operate proprietary production facilities, enabling direct control over R&D, prototyping, and final assembly. Buyers benefit from consolidated sourcing models—where a single supplier can deliver turnkey production lines including conveyors, robotic arms, and PLC-controlled workstations—with average lead times ranging from 45 to 90 days depending on customization scope. Localized access to CNC machining, sheet metal fabrication, and electrical integration services supports rapid iteration and cost-efficient scaling for both standard and engineered-to-order systems.

How to Choose Factory Automation Suppliers?

Evaluate potential partners using these critical criteria:

Production and Engineering Capacity

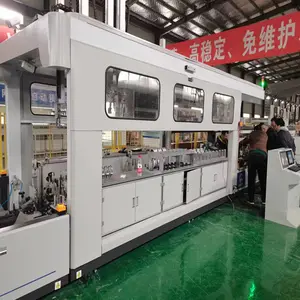

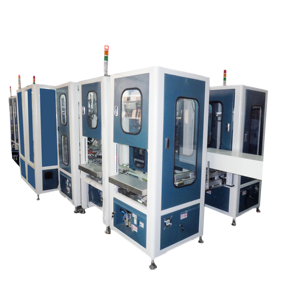

Confirm ownership of dedicated production lines and in-house engineering teams. Suppliers with end-to-end control over design, fabrication, and testing are better positioned to deliver reliable, scalable automation systems. Prioritize companies that disclose facility size, workforce composition, and technical capabilities such as PLC programming, HMI integration, and robotic cell configuration.

Quality and Compliance Verification

While formal certifications (e.g., ISO 9001, CE) are not explicitly stated in available data, assess compliance indirectly through delivery performance and transaction history. CE marking is essential for EU market entry, ensuring alignment with machinery safety directives. Request documentation for electrical system standards, sensor calibration, and mechanical safety interlocks prior to deployment.

Customization and Technical Support

Most leading suppliers offer full customization of color, material specifications, labeling, and functional parameters. Confirm whether the supplier provides pre-shipment testing reports, 3D layout designs, or remote commissioning support. Response time and reorder rate serve as proxies for service reliability—suppliers maintaining ≤2-hour response times and >100% reorder rates indicate strong post-sale engagement.

Transaction and Risk Mitigation

Utilize secure payment mechanisms tied to milestone verification. Require performance guarantees for system uptime, cycle time accuracy, and fault recovery. For high-value orders (>$100,000), insist on factory audits or video walkthroughs of completed production lines before shipment. Sample validation is recommended for complex systems, particularly in lithium-ion battery or household appliance automation.

What Are the Best Factory Automation Suppliers?

| Company Name | Location | Verification Type | Main Products | Price Range (Min. Order) | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Sun Laser Technology Co., Ltd. | Guangdong, CN | Multispecialty Supplier | Automated battery production lines, LiFePO4 cell & pack assembly systems | $137K–$428K (1 acre) | 100% | ≤3h | US $60,000+ | 100% |

| Guangdong Huixing Hitech Co., Ltd. | Guangdong, CN | Custom Manufacturer | TV, LED/LCD, washing machine automatic assembly lines | $2,000–$3,000 (1 set) | - | ≤23h | US $80+ | 100% |

| Guangdong Huazhe Intelligent Manufacturing Co., Ltd. | Guangdong, CN | Custom Manufacturer | Lithium battery production lines, automatic coating & spraying systems | $1,000–$1,500 (1 piece/set) | 33% | ≤2h | US $20,000+ | <15% |

| Shandong Huiyao Laser Technology Co., Ltd. | Shandong, CN | Multispecialty Supplier | EV battery assembly lines, aluminum sheet processing systems | $1,000–$1M (1 set/acre) | 66% | ≤2h | US $10,000+ | <15% |

Performance Analysis

Shenzhen Sun Laser stands out with a verified 100% on-time delivery and reorder rate, indicating consistent execution and customer satisfaction for high-capacity battery automation systems. Despite higher price points tied to large-scale installations ("per acre"), its track record supports suitability for mission-critical deployments. Guangdong Huixing Hitech offers competitively priced assembly lines with full customization, though extended response times (≤23h) may impact project agility. Guangdong Huazhe and Shandong Huiyao provide lower-cost entry points and fast responsiveness but exhibit suboptimal delivery performance (33–66%) and low reorder rates, suggesting potential gaps in fulfillment consistency or after-sales support. Buyers should prioritize suppliers with transparent capacity metrics and proven scalability for long-term automation integration.

FAQs

How to verify factory automation supplier reliability?

Cross-check declared production capabilities with order history and delivery performance. Request evidence of past installations, client references, and system validation reports. Video audits of operational production lines can confirm technical proficiency and workflow organization.

What is the typical lead time for automated production lines?

Standard configurations require 45–60 days for manufacturing and testing. Fully customized systems, especially those involving robotics or specialized process integration (e.g., battery coating or sealing), may take 75–90 days. Shipping via sea freight adds 20–35 days for international destinations.

Do suppliers support OEM and ODM customization?

Yes, most suppliers listed offer comprehensive customization including color, material selection, branding (logo, labels, packaging), and functional adaptations. Technical modifications require detailed specifications in CAD or 3D format, with prototypes typically delivered within 4–6 weeks.

What are common minimum order quantities (MOQ)?

MOQs vary by system type: modular units (e.g., spraying stations) start at 1 piece, while full production lines require minimum site allocations (e.g., "1 acre"). Some suppliers allow pilot runs with reduced scope for initial validation.

Can automation systems be shipped globally?

All major suppliers support international shipping. Confirm Incoterm preferences (FOB, CIF) and ensure compliance with destination regulations for electrical and mechanical equipment. Crated shipments with IP-rated enclosures are standard for overseas transport.