Factory Erp System

CN

CN

CN

CN

CN

CN

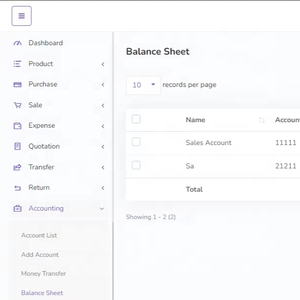

About factory erp system

Where to Find Factory ERP System Suppliers?

Asia has emerged as a central hub for enterprise resource planning (ERP) software development, with concentrated expertise in China and India enabling cost-efficient, scalable solutions for global manufacturers. Chinese suppliers, particularly in Shanghai and Shenzhen, operate within integrated technology ecosystems that combine advanced R&D infrastructure with access to skilled software engineering talent. Indian firms, especially in regions like Hyderabad and Bangalore, leverage strong IT outsourcing traditions and multilingual technical teams to deliver cloud-based ERP systems tailored to international compliance standards.

These regional clusters support rapid deployment of modular ERP platforms integrating production scheduling, inventory control, financial management, and supply chain modules. Suppliers benefit from mature development pipelines—many maintain agile teams capable of parallel customization projects—reducing implementation lead times by 30–50% compared to in-house development. Buyers gain access to flexible engagement models, including one-time licensing, subscription-based SaaS, and fully customized builds, often at 40–60% lower total cost of ownership than Western-developed equivalents.

How to Choose Factory ERP System Suppliers?

Prioritize these verification protocols when selecting partners:

Technical Capability Assessment

Verify proven experience in manufacturing-specific ERP implementations, including integration with MES (Manufacturing Execution Systems), IoT-enabled machine monitoring, and real-time shop floor data synchronization. Demand documentation of system architecture, API compatibility, and database scalability (e.g., support for MySQL, PostgreSQL, or Oracle backends).

Development & Customization Infrastructure

Evaluate supplier capabilities through the following benchmarks:

- Minimum team size of 10+ developers with demonstrated ERP project portfolios

- Offering of modular customization (e.g., financial, HR, procurement, production modules)

- Support for cloud-hosted, on-premise, or hybrid deployment models

Cross-reference response time metrics (target ≤8 hours) and on-time delivery records to assess operational reliability.

Transaction & Intellectual Property Safeguards

Require clear service agreements outlining data security protocols, source code ownership, and post-implementation support terms. Utilize secure payment mechanisms such as escrow services for milestone-based payments. Conduct due diligence via platform-verified transaction histories and request client references for similar-scale deployments before contract finalization.

What Are the Best Factory ERP System Suppliers?

| Company Name | Location | Product Range | Starting Price | Min. Order | On-Time Delivery | Avg. Response | Customization | Service Type |

|---|---|---|---|---|---|---|---|---|

| HANGZHOU ALLROOT Software Co., Ltd. | Zhejiang, CN | 3 products | $100 | 1 piece | 100% | ≤4h | Color logo, process customization | Multispecialty Supplier |

| KAEM SOFTWARES PRIVATE LIMITED | Tamil Nadu, IN | 5 products | $325 | 1–2 units | Not specified | ≤2h | Limited | Software Specialist |

| Shanghai Jigong Intelligent Information Technology Co., Ltd. | Shanghai, CN | 5 products | $1,000 | 1 piece | 100% | ≤11h | Production, finance, SCM modules | Multispecialty Supplier |

| Shenzhen Douples Technology Co., Ltd. | Guangdong, CN | 5 products | $500 | 1 unit | 100% | ≤8h | Netsuite/SAP integration, process dev | Trusted Service Provider |

| STEPMEDIA SOFTWARE VIET NAM COMPANY LIMITED | Hanoi, VN | 5 products | $5,000 | 1 unit | Not specified | ≤2h | Full custom ERP development | Software Specialist |

Performance Analysis

HANGZHOU ALLROOT and Shenzhen Douples demonstrate high reliability with 100% on-time delivery and responsive communication, making them suitable for time-sensitive deployments. KAEM SOFTWARES and STEPMEDIA stand out for rapid response times (≤2h), indicating strong customer service orientation despite limited public performance data. Shanghai Jigong offers mid-tier pricing with comprehensive module coverage, while STEPMEDIA targets high-end clients requiring bespoke development at premium price points ($5,000–$50,000). Suppliers in China dominate delivery assurance metrics, whereas Indian and Vietnamese firms emphasize affordability and adaptability for niche manufacturing workflows.

FAQs

How to verify factory ERP system supplier reliability?

Cross-check claimed development capabilities with portfolio reviews and client case studies. Request demonstration environments or trial access to evaluate UI/UX and system responsiveness. Validate technical support availability, including multilingual assistance and after-sales maintenance SLAs.

What is the typical implementation timeline?

Standard ERP deployments range from 4–12 weeks depending on integration complexity. Cloud-based systems with preconfigured templates can go live in under 30 days. Fully customized solutions, especially those interfacing with legacy machinery or external accounting platforms, may require 3–6 months.

Can ERP suppliers integrate with existing factory equipment?

Yes, reputable suppliers offer API-based connectivity with PLCs, SCADA systems, barcode scanners, and CNC machines. Confirm protocol support (e.g., OPC UA, MQTT, RESTful APIs) and request proof of prior integrations with similar hardware setups.

Do ERP vendors provide free trials or demos?

Most suppliers offer live demonstrations or time-limited sandbox environments. Full trial licenses are typically available upon qualification, though custom development quotes usually require paid scoping engagements.

How to initiate customization requests?

Submit detailed functional requirements including desired modules (e.g., production planning, quality control, CRM), user count, language preferences, and reporting needs. Leading suppliers respond with technical proposals, system diagrams, and implementation roadmaps within 5–7 business days.