Factory Production Control System

Top sponsor listing

Top sponsor listing

CN

CN

1/2

1/2

1/12

1/12

1/29

1/29

1/23

1/23

1/9

1/9

1/31

1/31

About factory production control system

Where to Find Factory Production Control System Suppliers?

China remains the global epicenter for factory production control system manufacturing, with key supplier clusters concentrated in Guangdong, Shanghai, and Hebei provinces. Shenzhen-based suppliers like Yuetian Micro Technology dominate in industrial automation components, offering integrated solutions including PLCs, HMIs, and variable frequency drives. Shanghai hosts engineering-focused firms such as Pony Engineering, specializing in process-specific DCS implementations for industries like glass and cement production. Meanwhile, Hebei-based machinery integrators—including Jiurui Machinery—combine control systems with turnkey production lines for construction materials, leveraging regional supply chain density to reduce component procurement lead times by 20–30%.

These industrial hubs provide access to vertically integrated ecosystems where hardware design, software programming, and system integration occur under one operational umbrella. Buyers benefit from proximity to tier-1 component suppliers (e.g., Siemens, Delta, Mitsubishi distributors), enabling rapid prototyping and scalable deployment. Typical advantages include lead times of 30–60 days for customized systems, MOQ flexibility down to single-unit sets, and cost efficiency driven by localized engineering talent and standardized compliance testing infrastructure.

How to Choose Factory Production Control System Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Integration Capability

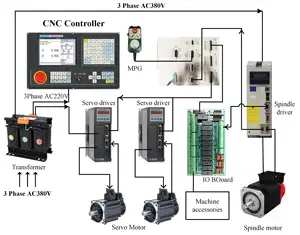

Verify adherence to IEC 61131-3 standards for programmable controller programming and confirm support for industrial communication protocols (e.g., Modbus, Profibus, EtherCAT). For international deployments, ensure CE or CCC certification is available upon request. Assess software compatibility with SCADA and MES platforms, particularly for smart factory integration. Suppliers should provide detailed architecture diagrams and HMI screen mockups during pre-sale consultation.

Production and Customization Capacity

Evaluate the following benchmarks:

- Proven experience in sector-specific applications (e.g., flat glass kilns, web tension control, FRP panel lines)

- In-house engineering teams capable of logic programming, panel assembly, and field commissioning

- Customization scope covering UI localization, alarm logging, remote monitoring, and IoT connectivity

Cross-reference product listings with on-time delivery performance (target ≥99%) and response time metrics (≤3 hours preferred) to assess service responsiveness.

Quality Assurance and Transaction Security

Prioritize suppliers with documented quality management systems and verifiable after-sales support structures. Where available, review online revenue indicators and reorder rates as proxies for customer satisfaction. Utilize secure payment mechanisms that release funds post-delivery verification. Request functional testing videos or on-site audits prior to shipment, especially for high-value systems exceeding $100,000 per set.

What Are the Best Factory Production Control System Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Product Range |

|---|---|---|---|---|---|---|---|

| Shenzhen Yuetian Micro Technology Co., Ltd. | Shenzhen, CN | PLC, PAC, HMI, VFD, Industrial PCs | 99% | ≤2h | 51% | US $1.4M+ | 14+ listed systems |

| Shanghai Pony Engineering Co., Ltd. | Shanghai, CN | DCS, Kiln Control, Glass Line Automation | 100% | ≤3h | - | - | 4 specialized systems |

| Qinhuangdao Dinuo Technology Development Co., Ltd. | Hebei, CN | FRP Panel Line Controls, Board Machinery | 100% | ≤2h | - | US $270K+ | 5 integrated line systems |

| Shijiazhuang Jiurui Machinery Co., Ltd. | Hebei, CN | PLC-Controlled Gypsum & Board Lines | 100% | ≤7h | - | - | 4 high-capacity systems |

| Shanghai Senming Industrial Equipment Co., Ltd. | Shanghai, CN | Web Guide, Tension, EPC Systems | - | ≤7h | <15% | US $1K+ | 5 web handling controls |

Performance Analysis

Shenzhen Yuetian stands out with the highest reorder rate (51%) and extensive product range across core automation components, indicating strong market retention and technical versatility. Shanghai Pony Engineering demonstrates perfect on-time delivery and specializes in advanced DCS applications for energy-intensive processes, though lacks public reorder data. Qinhuangdao Dinuo and Shijiazhuang Jiurui focus on vertical-specific turnkey systems, with pricing typically ranging from $60,000 to $290,000 per line, reflecting deep integration with material processing machinery. Shanghai Senming offers lower-cost entry points ($250–$1,200 per unit) but shows limited repeat business, suggesting niche applicability or service scalability constraints.

FAQs

How to verify factory production control system supplier reliability?

Confirm certifications (CE, ISO 9001) through official registries and request project references in your target industry. Analyze supplier tags related to delivery consistency and responsiveness. Conduct virtual factory audits to observe panel wiring practices, software testing procedures, and inventory management of critical components.

What is the typical lead time for customized control systems?

Standard configurations ship within 30 days. Fully customized systems with bespoke HMI interfaces or communication protocols require 45–60 days, depending on complexity. Add 7–14 days for international shipping via air or sea freight based on Incoterms.

Can suppliers integrate control systems with existing factory networks?

Yes, most established suppliers support OPC UA servers, MQTT brokers, and SQL database connectivity for enterprise-level integration. Confirm protocol compatibility and cybersecurity measures (e.g., firewall configuration, user role permissions) during technical scoping.

Do suppliers offer post-installation support?

Leading providers include remote troubleshooting, ladder logic updates, and operator training in their service packages. Some offer cloud-based monitoring dashboards. Clarify warranty terms (typically 12–24 months) and availability of on-site engineers for commissioning.

What are common customization options?

Buyers can specify input/output configurations, HMI language and layout, alarm histories, data logging intervals, and enclosure ratings (IP65/IP67 for harsh environments). OEM branding, color schemes, and labeling are also widely supported, particularly by engineering-centric firms like Pony Engineering.