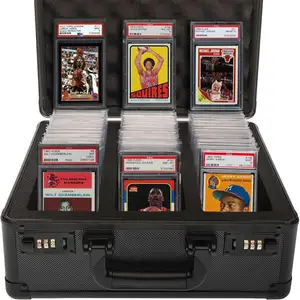

Factory Tool Box

Top sponsor listing

Top sponsor listing

About factory tool box

Where to Find Factory Tool Box Suppliers?

China remains the global epicenter for factory tool box manufacturing, with key production clusters in Zhejiang, Jiangsu, and Anhui provinces driving industrial output. Ningbo and Yongkang in Zhejiang are renowned for precision metal fabrication and tool storage systems, hosting vertically integrated facilities that support high-volume production of heavy-duty cabinets, mobile workbenches, and modular tool cases. These regions benefit from mature supply chains for cold-rolled steel, aluminum extrusions, and EVA foam linings, reducing material lead times by 20–30% compared to offshore alternatives.

The concentration of OEM and ODM manufacturers enables scalable production across diverse segments—from portable handheld toolboxes to multi-tier industrial cabinets. Buyers access a consolidated ecosystem where design, stamping, welding, powder coating, and assembly operations are co-located within 50 km, facilitating faster prototyping and order fulfillment. Average lead times for standard configurations range from 25–40 days, with customization options widely available for dimensions, load capacity, drawer layout, and labeling. Cost efficiencies stem from localized sourcing and automation, offering 15–25% lower unit prices than Western or Southeast Asian producers.

How to Choose Factory Tool Box Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional criteria:

Material & Construction Standards

Verify use of structural materials such as SPCC cold-rolled steel (≥1.0 mm thickness) for load-bearing cabinets, reinforced corner welds, and anti-corrosion treatments like zinc plating or epoxy-based powder coating. For impact-resistant plastic cases, confirm compliance with ASTM D695 for compressive strength. Fireproof variants should incorporate flame-retardant HDPE or ABS composites meeting UL 94 V-0 ratings.

Production Capacity Verification

Assess infrastructure through documented indicators:

- Minimum 100+ product listings in tool cabinets or cases to demonstrate specialization

- In-house capabilities in laser cutting, CNC bending, robotic welding, and UV printing for customization

- Monthly output capacity exceeding 5,000 units for bulk procurement scalability

Cross-reference on-time delivery rates (target ≥98%) and response times (ideally ≤3 hours) as proxies for operational reliability.

Customization & Compliance Readiness

Prioritize suppliers offering dimensional flexibility (standard widths: 48"–72"), modular drawer systems, lock integration, and branding via silk screening or laser etching. Confirm adherence to international safety standards—such as ANSI/BIFMA X5.3 for cabinet stability—and CE marking for European market access. Request test reports for salt spray resistance (≥500 hours) and dynamic load testing (≥150 kg per drawer).

What Are the Best Factory Tool Box Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Tier | Customization Options |

|---|---|---|---|---|---|---|

| Ningbo Sunyoung Enclosure Co., Ltd. | Tool Cases (1082), Electronics Enclosures (340) | 100% | ≤3h | 19% | US $1.9M+ | Trays, wheels, foam inlays, UV printing, laser etching, waterproof seals, explosion-proof materials |

| Yongkang Youren Trading Co., Ltd. | Tool Cabinets (321), Tool Sets (27) | 98% | ≤2h | <15% | US $210K+ | Size, style, frame, color, logo, packaging |

| Ningbo Pudel Industry And Trade Co., Ltd. | Tool Cases (184), Other Storage (2) | 100% | ≤1h | <15% | US $10K+ | Handle design, molded foam, hardware customization |

| Shanghai Zhenyi Office Furniture Co., Ltd. | Filing Cabinets (317), Conference Tables (73) | 100% | ≤7h | <15% | US $1K+ | Limited to industrial-grade metal cabinets |

| Chuzhou Yangzijiamei Technology Co., Ltd. | Tool Cabinets (147), Wardrobes (21) | 100% | ≤8h | - | - | Drawer count, size (48”/72”), stainless steel finish |

Performance Analysis

Ningbo Sunyoung leads in product breadth and customization depth, supported by robust online revenue and consistent 100% on-time delivery. Its specialization in enclosures aligns with high-precision tool storage needs, particularly for electronics and instrumentation sectors. Yongkang Youren offers competitive pricing and rapid responsiveness, making it suitable for mid-volume orders requiring fast turnaround. Ningbo Pudel distinguishes itself with sub-one-hour response times and direct sales models, though its lower reorder rate suggests room for customer retention improvement. Chuzhou Yangzijiamei focuses on large-format stainless steel cabinets, ideal for automotive and workshop environments demanding corrosion resistance. Shanghai Zhenyi, while technically capable, positions more broadly in office furniture, indicating less specialization in industrial tool storage.

FAQs

What is the typical MOQ for factory tool boxes?

Minimum order quantities vary by type: 1–10 sets for assembled cabinets, 10–30 pieces for mass-produced models. Some suppliers offer single-set sampling at premium pricing. Plastic-molded cases may require higher MOQs (500+ units) due to tooling costs.

How long does customization take?

Standard modifications (color, logo, tray layout) add 5–10 days to baseline lead times. Full structural redesigns or custom molding require 20–35 days, including prototype validation. Suppliers with in-house tooling and CNC processing can accelerate turnaround.

Are samples available before bulk ordering?

Yes, most suppliers provide paid samples. Costs typically range from $50–$300 depending on complexity and are often credited toward first production orders. Sample lead times average 7–15 days.

Can suppliers handle global shipping?

All listed suppliers support international export with FOB terms. Sea freight is standard for full-container loads (20’ or 40’). Buyers should confirm packaging specifications (e.g., wooden crates for heavy cabinets) and coordinate customs documentation for smooth clearance.

What quality control measures should be verified?

Request evidence of incoming material inspection, in-process welding audits, final load testing, and packaging checks. Third-party inspection services (e.g., SGS, TÜV) can conduct pre-shipment verification for critical orders. Video audits of production lines enhance transparency for remote buyers.