Fanuc Cnc System

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

CN

CN

CN

CN

About fanuc cnc system

Where to Find Fanuc CNC System Suppliers?

China remains a central hub for industrial automation and CNC machinery production, with key supplier clusters concentrated in Shandong and Beijing. Shandong province hosts multiple integrated manufacturing facilities specializing in CNC machining centers, milling machines, and lathe systems equipped with Fanuc controls. The region benefits from mature industrial ecosystems, including access to precision casting, ball screw manufacturing, and spindle assembly networks, reducing component lead times by up to 25% compared to non-specialized regions.

Suppliers in Jinan and Qingdao offer vertically integrated production lines capable of delivering complete CNC systems—from structural frame fabrication to control panel integration. These facilities typically maintain in-house R&D teams focused on system optimization, including thermal stabilization, automatic tool changers (ATC), and multi-axis synchronization. Buyers gain operational advantages through localized supply chains that support both standard configurations and engineered-to-order solutions, with average production lead times ranging from 30–45 days for full machine builds.

How to Choose Fanuc CNC System Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Integration Expertise

Verify that suppliers demonstrate proven integration of Fanuc CNC systems, including FANUC 18i, 16i, and 0i series controllers. Confirm compatibility with absolute position sensors, optical rulers, and rotary table interfaces. For high-precision applications, assess implementation of spindle thermal stabilization and vibration-damping granite bed designs. CE marking or equivalent safety certification should be present for export compliance.

Production Capability Verification

Evaluate infrastructure indicators:

- Facility size exceeding 5,000m² to ensure scalable output

- In-house machining capabilities for guide ways, tool magazines, and coupling systems

- Customization capacity for material feed systems, chip conveyors, and coolant management (e.g., oil separators, automatic shutdown)

- Provision of OEM/ODM services, including branding, packaging, and color customization

Cross-reference online transaction data with on-time delivery performance—target suppliers achieving ≥98% fulfillment rates. Response time under 3 hours indicates strong customer service infrastructure.

Transaction Risk Mitigation

Utilize secure payment frameworks such as escrow services to align payment milestones with delivery and inspection phases. Prioritize suppliers with documented quality management systems and verifiable after-sales support, including remote diagnostics and operator panel training. Request product-specific testing reports, particularly for axis positioning accuracy (ISO 230-2 compliance) and continuous operation endurance.

What Are the Best Fanuc CNC System Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Verified Type |

|---|---|---|---|---|---|---|---|---|

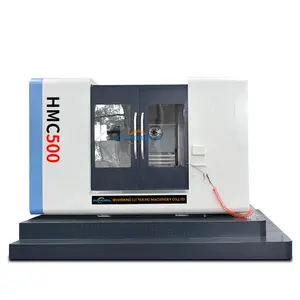

| Shandong Lu Young Machinery Co., Ltd. | Shandong, CN | CNC Lathe, Machining Centre, Milling Machines, Band Saw | US $120,000+ | 100% | ≤2h | 40% | Controller config, security door, tool changer, thermal stabilization, operator panel | Multispecialty Supplier |

| Shandong Weste Cnc Machine Tool Co., Ltd. | Shandong, CN | Machining Centre, CNC Milling, Manual Mills, Drilling Machines | US $30,000+ | 100% | ≤3h | 100% | - | - |

| Skymach (Shandong) Intelligent Equipment Co., Ltd. | Shandong, CN | Gantry Milling, Vertical Machining Centers | US $110,000+ | 100% | ≤2h | 25% | Spindle taper, ATC, tool magazine, ball screw, logo, packaging | Custom Manufacturer |

| Beijing Deraya Technology Co., Ltd. | Beijing, CN | 5-Axis Vertical & Horizontal Machining Centers | - | 100% | ≤3h | - | Color, material, size, logo, graphic, packaging | Multispecialty Supplier |

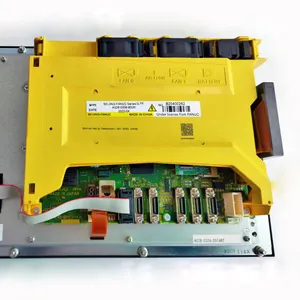

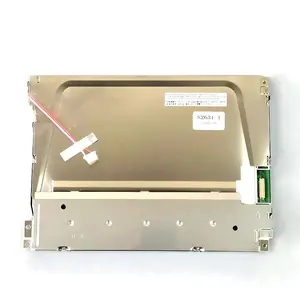

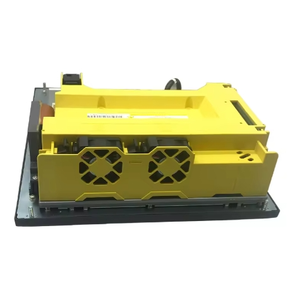

| Shenzhen Newai Technology Co., Ltd. | Guangdong, CN | Fanuc Control Modules, Simulators, CNC System Components | US $40,000+ | 100% | ≤1h | 19% | - | Multispecialty Supplier |

Performance Analysis

Shandong-based manufacturers dominate full-machine supply, offering comprehensive Fanuc-integrated systems with strong customization depth. Shandong Lu Young and Skymach provide extensive engineering options, including thermal stabilization and automated tooling, making them suitable for high-accuracy environments. Shandong Weste stands out with a 100% reorder rate, indicating strong customer satisfaction despite limited customization visibility.

Beijing Deraya focuses on premium 5-axis vertical and horizontal machining centers with six-figure pricing, targeting aerospace and mold-making sectors requiring sub-micron repeatability. Meanwhile, Shenzhen Newai serves a niche role as a component-level supplier, offering original Fanuc modules (e.g., A02B-0333-B500), simulators, and replacement parts at unit prices starting below $5, ideal for maintenance and retrofitting projects.

FAQs

How to verify Fanuc CNC system supplier reliability?

Confirm technical documentation for Fanuc control integration, including wiring diagrams, parameter settings, and alarm diagnostics. Request proof of after-sales service capability, such as remote connectivity support or field technician availability. Validate business credentials through third-party verification platforms and cross-check claimed certifications (e.g., ISO 9001) with issuing bodies.

What is the typical MOQ and lead time?

Minimum order quantity is generally 1 unit for complete CNC machines and 1 piece for control modules. Standard lead time ranges from 30–45 days for machine builds, depending on complexity. Component-level orders (e.g., Fanuc modules) can ship within 3–7 days. Expedited production may reduce timelines by 10–15% with additional fees.

Do suppliers support customization?

Yes, especially among verified custom manufacturers. Common options include spindle configuration, tool magazine capacity, chip conveyor layout, enclosure design (security doors), and operator interface panels. Full OEM branding—including color, logo, packaging, and manuals—is available upon request.

Can Fanuc CNC systems be retrofitted or simulated?

Several suppliers offer Fanuc cnc simulators (e.g., A02B-0321-B500) for training and programming validation. Retrofit kits and individual modules (e.g., A76L-0300-001) are available for legacy machine upgrades, enabling modern control integration without full system replacement.

What are the shipping and logistics considerations?

Complete CNC machines are typically shipped via sea freight (FOB or CIF terms), requiring proper crating and export documentation. Component shipments can be dispatched via air courier for urgent needs. Confirm incoterms, insurance coverage, and destination import regulations—especially for electrical and automation equipment—prior to order finalization.