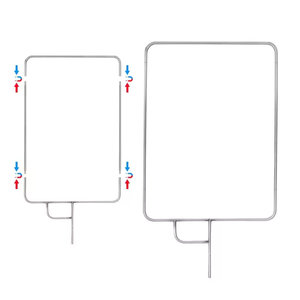

Flash Diffuser

1/1

1/1

1/18

1/18

1/3

1/3

1/17

1/17

0

0

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/36

1/36

1/3

1/3

1/34

1/34

1/3

1/3

1/3

1/3

1/28

1/28

1/3

1/3

0

0

1/3

1/3

About flash diffuser

Where to Find Flash Diffuser Suppliers?

China leads global production of photographic lighting accessories, with key manufacturing clusters in Shenzhen and Guangzhou specializing in compact, high-efficiency flash diffusers. These regions host vertically integrated supply chains that combine precision tooling, injection molding, and textile processing under one ecosystem. Shenzhen’s proximity to Hong Kong enables rapid export logistics, reducing shipping lead times by 10–15 days compared to inland hubs. Guangzhou’s industrial base emphasizes cost-effective fabrication of reflective materials and collapsible softbox frames, leveraging localized access to aluminum alloys and diffusion fabrics.

The concentration of component suppliers—such as silicone molders, fabric coaters, and magnetic fixture manufacturers—within 30km radii allows for agile prototyping and just-in-time assembly. This integration supports MOQs as low as 1 piece for standard models while maintaining per-unit costs 20–40% below Western equivalents. Buyers benefit from scalable output, with top-tier factories reporting monthly production capacities exceeding 50,000 units across multiple product lines, including parabolic modifiers, bounce domes, and foldable lanterns.

How to Choose Flash Diffuser Suppliers?

Evaluate potential partners using the following verification criteria:

Technical Compliance

Confirm adherence to international safety and material standards, including RoHS for restricted substances and REACH for chemical compliance. While formal ISO 9001 certification is not universally present, prioritize suppliers documenting internal quality control protocols—especially for optical consistency in diffusion layers and structural durability in folding mechanisms.

Production Capability Audits

Assess operational scale and technical flexibility through verifiable metrics:

- Minimum facility size supporting dedicated assembly lines (e.g., >3,000m²)

- In-house design teams enabling rapid customization of shape, color temperature, or mounting systems

- Integrated material sourcing for key components: heat-resistant silicones, silver-coated ripstop nylon, and rare-earth magnets

Cross-reference on-time delivery rates (target ≥99%) with response times (ideally ≤6 hours) to gauge operational responsiveness.

Transaction Safeguards

Utilize secure payment frameworks such as trade assurance programs to mitigate risk during initial procurement. Request physical samples before bulk ordering to validate light dispersion performance and build quality. Verify packaging integrity for shock and moisture resistance, particularly for export shipments containing delicate plastic or spring-wire components.

What Are the Best Flash Diffuser Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity | Product Range |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Hqs Technology Co., Ltd. | Shenzhen, CN | US $610,000+ | 99% | ≤10h | <15% | Color, material, size, logo, packaging | 5–50 pieces | Foldable softboxes, universal diffusers |

| Shenzhen Lovefoto Technology Co., Ltd. | Shenzhen, CN | US $480,000+ | 99% | ≤8h | 19% | Color, material, size, logo, packaging | 10–100 pieces | Mini softboxes, conical condensers, bounce diffusers |

| Shenzhen LGYD Electronics Co., Ltd. | Shenzhen, CN | US $220,000+ | 97% | ≤5h | <15% | Color, material, size, logo, packaging | 1 piece | Lantern softboxes, octagonal parabolic diffusers |

| Ningbo Focus Studio Equipment Co., Ltd. | Ningbo, CN | US $10,000+ | 100% | ≤1h | <15% | Reflector types, modular configurations | 10–20 pieces | Standard reflectors, magnetic silicone diffusers |

| Guangzhou Hengming Electronics Co., Ltd. | Guangzhou, CN | US $50,000+ | 100% | ≤6h | 20% | Limited (product-specific) | 1 piece/set | Magnetic softboxes, beauty dishes, gel filters |

Performance Analysis

Shenzhen-based suppliers dominate in scalability and customization breadth, with Hqs Technology achieving the highest online revenue and a 99% on-time delivery rate despite sub-15% reorder frequency—indicative of strong new buyer acquisition. Lovefoto Technology balances volume production with diverse diffuser types, supporting MOQs from 10 units. LGYD Electronics stands out for single-piece sampling, ideal for small studios testing product fit. Ningbo Focus excels in responsiveness (≤1h average reply) and perfect shipment adherence, though its lower transaction volume suggests niche positioning. Guangzhou Hengming, while smaller in revenue, offers technically advanced magnetic and parabolic designs with full single-unit availability.

FAQs

How to verify flash diffuser supplier reliability?

Cross-check self-reported metrics such as on-time delivery and response time against platform-backed transaction histories. Request evidence of quality control procedures, including batch testing for material consistency and structural fatigue. Prioritize suppliers offering customization options, as this indicates in-house design and tooling capabilities.

What is the typical sampling timeline?

Standard sample fulfillment ranges from 3–7 days for in-stock items. Custom prototypes require 10–15 days depending on complexity. Air freight adds 5–12 days globally, making total lead time 8–25 days from order to receipt.

Can suppliers ship flash diffusers worldwide?

Yes, all listed suppliers support international shipping via express carriers and sea freight. Confirm Incoterms (FOB, CIF) early in negotiation. Most provide automated shipping quotes based on destination and order volume.

Do manufacturers offer free samples?

Free samples are uncommon for low-cost items like mini diffusers. However, many suppliers credit sample expenses toward first bulk orders (typically 100+ units). For higher-value products (e.g., parabolic softboxes), paid sampling at 50–70% of retail price is standard.

How to initiate customization requests?

Submit detailed specifications covering dimensions, diffusion material (e.g., silk, satin, grid density), attachment mechanism (shoe mount, magnetic, Velcro), and branding requirements. Suppliers with dedicated R&D teams can return CAD renderings or physical mockups within 7–10 days.