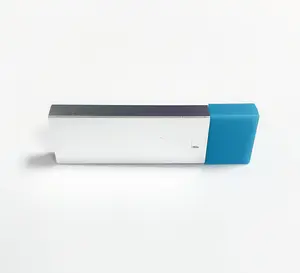

Flash Memory

Top sponsor listing

Top sponsor listing

1/22

1/22

1/18

1/18

1/3

1/3

1/17

1/17

1/3

1/3

1/18

1/18

1/2

1/2

0

0

1/1

1/1

1/15

1/15

1/3

1/3

1/2

1/2

1/46

1/46

1/3

1/3

1/3

1/3

About flash memory

Where to Find Flash Memory Suppliers?

China remains the central hub for global flash memory production, with Shenzhen emerging as the dominant manufacturing and export cluster. This region hosts a high concentration of electronics manufacturers specializing in USB drives, memory cards, and customized storage solutions, supported by vertically integrated supply chains for NAND chips, PCBs, and plastic/metal enclosures. The ecosystem enables rapid prototyping, scalable production runs, and cost-efficient material sourcing—critical advantages for bulk procurement and custom branding initiatives.

Suppliers in this cluster benefit from proximity to component distributors, packaging vendors, and logistics networks, reducing lead times and coordination overhead. Most facilities operate automated assembly lines capable of producing 50,000–200,000 units monthly, depending on complexity and customization level. Buyers gain access to flexible MOQs (as low as 5–100 pieces), competitive pricing structures, and responsive communication channels, with many suppliers offering sub-4-hour response times and 95%+ on-time delivery performance.

How to Choose Flash Memory Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Production & Customization Capability

Assess whether suppliers support required customization options including logo engraving, color/material selection, capacity grading (8GB–128GB), and unique form factors (3D shapes, PVC molds, business card designs). Prioritize manufacturers with in-house design and molding capabilities, especially for promotional or corporate-branded products. Confirm compatibility with USB 2.0/3.0 standards and verify chip quality—prefer suppliers using Grade A NAND flash for durability and data retention.

Quality Assurance & Compliance

While formal certifications (e.g., ISO 9001, CE, RoHS) are not universally declared in available data, buyers should request compliance documentation prior to order placement. Validate product reliability through sample testing, focusing on write/read speeds, plug-in cycle endurance (>5,000 insertions), and data retention (>10 years under standard conditions). For regulated markets, ensure electromagnetic compatibility (EMC) and safety certifications are obtainable upon request.

Operational Metrics & Transaction Safety

Evaluate supplier performance using key indicators:

- On-time delivery rate ≥95%

- Response time ≤4 hours (top performers achieve ≤1 hour)

- Reorder rate >20% as an indicator of customer satisfaction

- Minimum order quantity (MOQ) aligned with demand volume (ranging from 5 to 1,000 units)

Cross-check online revenue estimates where available (e.g., US $120,000–$360,000+) as a proxy for scale and market presence. Utilize secure payment mechanisms and consider partial shipments for initial validation before scaling orders.

What Are the Best Flash Memory Suppliers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Baolifeng Opto-Elec Co., Ltd. | USB Flash Drives, Memory Cards, Headphones | Color, size, logo, packaging, engraving, capacity | 100% | 22% | ≤1h | US $360,000+ | 100 pcs | $1.50–2.80 |

| Gaoyao Nanan Xinyipin Hardware And Plastic Factory | Custom USB Drives, PVC & 3D Designs | Shape, mold, printing, logo, material, 3D mockup | 95% | 20% | ≤4h | US $260,000+ | 100 pcs | $1.50–3.50 |

| Shenzhen Huawanda Electronics Co., Ltd. | USB 2.0 Drives, Full Printing, Business Series | Color, design, logo, packaging, capacity | 100% | 25% | ≤3h | US $220,000+ | 100 pcs | $1.50–14.99 |

| Time Gifts Trading | USB 2.0/3.0 Flash Drives | Limited customization (product data not detailed) | - | - | ≤4h | - | 300–500 pcs | $2–5 |

| Shenzhen Jintian Tech Development Co., Ltd. | KDATA Branded USB Drives, High-Capacity Models | Logo, packaging, label, graphic, engraving | 99% | <15% | ≤2h | US $120,000+ | 5–50 pcs | $0.79–4.18 |

Performance Analysis

Shenzhen-based suppliers dominate in responsiveness and delivery consistency, with three out of five achieving 99–100% on-time fulfillment and sub-3-hour average response times. Shenzhen Baolifeng and Huawanda demonstrate strong reorder rates (22% and 25%), indicating repeat buyer confidence, while Jintian Tech offers the lowest MOQs (down to 5 pieces), ideal for sampling or niche marketing campaigns. Gaoyao Nanan specializes in creative PVC and 3D-formatted drives, catering to promotional product distributors. Time Gifts Trading presents higher entry barriers due to larger MOQs and incomplete performance metrics, suggesting suitability only after direct verification.

FAQs

How to verify flash memory supplier reliability?

Request evidence of production infrastructure via facility videos or third-party audit reports. Verify consistency between listed product specifications and actual samples. Check historical transaction data, focusing on delivery adherence and post-sale communication. For long-term partnerships, confirm availability of ISO certification and environmental compliance (RoHS).

What is the typical lead time for custom flash drives?

Standard production lead time ranges from 7–15 days after artwork approval. Complex designs involving custom molds or 3D printing may extend to 20–25 days. Add 5–10 days for international air shipping or 25–40 days for sea freight depending on destination.

Can suppliers provide pre-production samples?

Yes, most suppliers offer samples for $0.79–$5.00 per unit, often refundable against bulk orders. Sample production typically takes 3–7 days, allowing buyers to validate build quality, data transfer performance, and branding accuracy before mass production.

Are there minimum order requirements for customized flash drives?

MOQs vary by supplier and complexity: basic logo printing starts at 5–100 units, while custom molds or shaped drives require 300–1,000 units. Low-MOQ suppliers like Shenzhen Jintian Tech enable small-scale testing, whereas specialized designs demand higher volumes to justify tooling costs.

How is data loading and security handled during manufacturing?

Reputable suppliers offer pre-loading services (e.g., branded content, software, encrypted files) under NDA agreements. Confirm that internal workflows include data wiping protocols post-production and secure handling procedures to prevent unauthorized access or duplication.