Flat Files Producer

About flat files producer

Where to Find Flat Files Producers?

China remains the global epicenter for flat files manufacturing, with key production clusters in Tianjin, Foshan, Nanhe, Nanjing, and Shanghai. These regions host vertically integrated facilities specializing in hand tool fabrication, leveraging localized steel supply chains and mature industrial ecosystems. Proximity to raw material sources and component suppliers enables cost reductions of 15–25% compared to Western producers, while established logistics networks support efficient export operations to North America, Europe, and Southeast Asia.

Suppliers in these hubs operate dedicated production lines for carbon steel, alloy steel, and diamond-coated flat files, with capabilities spanning forging, heat treatment, surface coating, and handle assembly. Facilities typically maintain monthly output capacities ranging from 50,000 to over 200,000 units, accommodating both bulk orders and customized configurations. The concentration of technical labor and supporting industries within 50km radii ensures shorter lead times—averaging 20–35 days for standard container shipments—and greater flexibility in order scaling.

How to Choose Flat Files Producers?

Effective supplier selection requires systematic evaluation across three core areas:

Production and Technical Capability

Assess infrastructure maturity through verifiable metrics:

- Confirmed ownership of in-house production lines (e.g., stamping, grinding, tempering)

- Minimum workforce of 50+ personnel with dedicated quality control teams

- Monthly production capacity exceeding 50,000 units for stable supply continuity

Cross-reference product listings with on-time delivery performance; prioritize suppliers maintaining ≥93% fulfillment rates.

Quality Assurance and Compliance

Verify adherence to international standards:

- ISO 9001 certification as a baseline for quality management systems

- Material traceability documentation for carbon steel or alloy compositions

- Surface hardness testing reports (e.g., HRC 58–62 for industrial-grade tools)

For diamond-coated variants, confirm electroplating thickness and grit consistency (e.g., 120–180 grit).

Transaction Reliability and Service Metrics

Analyze operational responsiveness and buyer protection indicators:

- Response time ≤4 hours, with top-tier suppliers achieving ≤2 hours

- Reorder rate below 17% indicating broad market reach without over-reliance on single clients

- Use of secure transaction mechanisms such as escrow or trade assurance programs

Prioritize suppliers with documented export experience and multilingual support for smoother procurement cycles.

What Are the Leading Flat Files Producers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order (Pieces) | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Tianjin Ruixin Tools & Hardware Co., Ltd. | Tianjin, CN | Files & Rasps (95), Wrench (136) | US $20,000+ | 100% | ≤2h | <15% | 1–100 | $0.15–0.80 |

| Foshan Xingong Haozhe Hardware Tools Co., Ltd. | Foshan, CN | Abrasive Tools (95), Files & Rasps (70) | US $50,000+ | 93% | ≤4h | 15% | 1–100 | $0.42–8.50 |

| Nanhe Jiufeng Steel File Factory | Nanhe, CN | Files & Rasps (152), Glass Cutters (28) | US $600+ | 50% | ≤2h | <15% | 100–1000 | $0.48–3.50 |

| NANJING OV INDUSTRY CO., LIMITED | Nanjing, CN | Files & Rasps (41), Axe (35) | US $120,000+ | 100% | ≤3h | <15% | 120 | $0.35–0.75 |

| Armor Diamond Tools (Shanghai) Co., Ltd. | Shanghai, CN | Glass Cutters (110), Milling Cutter (67) | US $30,000+ | 94% | ≤2h | 17% | 10–100 | $1.20–7.00 |

Performance Analysis

Tianjin Ruixin and NANJING OV demonstrate strong reliability with 100% on-time delivery and rapid response times, making them suitable for time-sensitive procurement. Foshan Xingong offers premium industrial-grade and diamond-inclined file options at higher price points, reflecting advanced processing capabilities. Nanhe Jiufeng, despite high listing volume, shows a significantly lower on-time delivery rate (50%), suggesting potential fulfillment risks. Armor Diamond Tools specializes in high-margin diamond-coated solutions, targeting niche applications in metalworking and mold finishing. Suppliers with online revenues exceeding US $50,000—particularly Foshan Xingong and NANJING OV—indicate scalable operations and consistent market demand.

FAQs

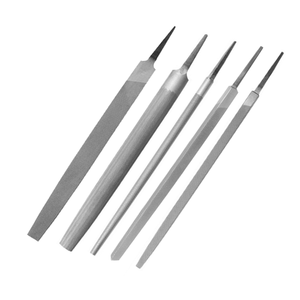

What materials are commonly used in flat files production?

Carbon steel (C65/C70) is standard for general-purpose files, offering optimal hardness after heat treatment. Alloy steel variants enhance wear resistance, while aluminum files serve lightweight applications. Diamond-coated surfaces utilize electroplated CVD diamond particles for precision work on hardened metals and composites.

What is the typical MOQ for flat files?

MOQs range from 1 piece for sample testing to 1,000 pieces for bulk pricing. Most suppliers set minimums between 100–120 pieces per order. Lower MOQs are available for high-value items like diamond files, often requiring 10–20 units per batch.

Are customization options available?

Yes, leading producers offer OEM/ODM services including custom tooth patterns (single-cut, double-cut), handle designs (wood, plastic, dual-color), and branding via laser engraving or stamping. Prototypes can typically be delivered within 10–15 days upon specification approval.

How to verify production claims?

Request factory audit reports, facility videos, or third-party inspection records. Confirm production line ownership by reviewing equipment lists and process flowcharts. Use video calls to validate CNC machining, grinding, and packaging stations before placing large orders.

What are standard lead times and shipping options?

Production lead time averages 15–25 days post-deposit. Air freight delivers samples in 5–7 days; sea freight for full containers takes 25–35 days depending on destination. FOB terms are standard, though some suppliers offer CIF arrangements with customs documentation support.