Flexible Factory Automation

CN

CN

CN

CN

About flexible factory automation

Where to Find Flexible Factory Automation Suppliers?

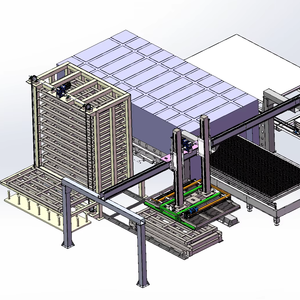

China remains the global epicenter for flexible factory automation systems, with key manufacturing clusters in Zhejiang, Shandong, and Beijing offering specialized capabilities. These regions host vertically integrated suppliers combining R&D, component fabrication, and system integration under one roof. The concentration of industrial automation expertise enables rapid prototyping, scalable production, and cost-efficient customization—critical for deploying modular assembly lines across diverse sectors including electrical components, furniture hardware, and energy metering.

Suppliers in these hubs benefit from mature ecosystems where PLC programming, mechanical engineering, and conveyor integration coexist within tight geographic proximity. This facilitates faster project execution, with typical lead times ranging from 30 to 60 days depending on complexity. Buyers gain access to turnkey solutions—from compact educational trainers to full-scale automated production lines—supported by local supply chains that reduce material costs by 15–25% compared to Western counterparts. The presence of standardized subsystems (e.g., modular conveyors, robotic arms, vision inspection) further enhances flexibility for reconfigurable manufacturing environments.

How to Choose Flexible Factory Automation Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm supplier expertise in designing scalable automation architectures. Prioritize companies demonstrating experience with PLC-controlled systems, sensor integration, and human-machine interfaces (HMI). For industrial deployments, verify compatibility with Industry 4.0 protocols such as OPC UA or MQTT. Educational or training-focused systems should include curriculum-aligned control software and fault simulation modules.

Production Infrastructure Assessment

Evaluate core manufacturing competencies through objective indicators:

- Ownership of end-to-end production lines—not just assembly but machining, wiring, and testing

- Demonstrated capacity for both high-value systems (>$300,000) and mid-range units ($50,000–$150,000)

- In-house engineering teams capable of customizing workflows for specific product types (e.g., circuit breakers, drawer slides, signal lamps)

Cross-reference product listings with on-time delivery performance (target ≥93%) and response efficiency (≤8 hours) to assess operational reliability.

Quality & Transaction Assurance

While formal certifications (ISO 9001, CE) are not explicitly stated in available data, buyers must request documented compliance with IEC standards for electrical safety and electromagnetic compatibility. Utilize secure payment mechanisms and require pre-shipment inspections. Request video walkthroughs of completed systems in operation to validate functionality before shipment. Sampling is strongly advised—especially for customized configurations—to verify cycle time accuracy, defect detection rates, and ease of reprogramming.

What Are the Best Flexible Factory Automation Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|

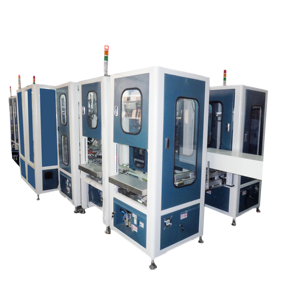

| Benlong Automation Technology Co., Ltd. | Electrical equipment assembly lines (MCCB, MCB, energy meters) | $10,000–$450,000 | 1 set | 100.0% | ≤2h | Not disclosed | Not disclosed |

| LEATOP INDUSTRIES CO.,LIMITED | Furniture hinge and drawer slide production systems | $29,300–$169,000 | 1 set | 100.0% | ≤8h | US $30,000+ | Not disclosed |

| Beijing Qyx Technology Co., Ltd. | Educational PLC automation trainers and lab systems | $7,129–$52,000 | 1 set | 100.0% | ≤9h | Not disclosed | Not disclosed |

| Shanghai Plastlink Transmission Equipment Co., Ltd. | Flexible conveyors, modular transfer lines, plastic chains | $4–$1,300 | 1 unit/meter | 93.0% | ≤3h | US $50,000+ | 38% |

| Qingdao Senger Intelligent Equipment Co., Ltd. | Fully automatic CNC bending machines and production lines | $50,000–$59,999 | 1 set | 100.0% | ≤1h | Not disclosed | Not disclosed |

Performance Analysis

Benlong Automation stands out for high-investment industrial clients, offering complete turnkey lines for electrical device manufacturing at scale. LEATOP specializes in niche furniture automation, particularly soft-close hinge and bearing slide systems, with strong pricing segmentation. Beijing Qyx targets academic and vocational institutions with certified training platforms, ideal for STEM and industrial automation curricula. Shanghai Plastlink provides component-level flexibility with low-MOQ modular conveyors, making it suitable for incremental line upgrades. Qingdao Senger delivers standardized yet intelligent bending cells, notable for uniform pricing and sub-hour responsiveness—indicative of streamlined sales operations.

FAQs

How to verify flexible automation supplier credibility?

Request detailed technical documentation including electrical schematics, PLC ladder logic samples, and risk assessments. Validate past project references, especially installations in your target industry. Conduct virtual audits via live video tours of running production lines to confirm build quality and process discipline.

What is the typical lead time for custom automation systems?

Standard configurations ship within 30–45 days. Customized systems requiring new tooling or software development typically require 50–75 days. Expedited builds may be possible for an additional fee, subject to component availability and engineering bandwidth.

Can suppliers support global installation and commissioning?

Some suppliers offer remote commissioning support via video guidance. On-site technician deployment is often available at additional cost, covering setup, calibration, and operator training. Clarify service terms—including travel expenses and warranty coverage—before contract finalization.

Is customization available for existing automation platforms?

Yes, most suppliers support retrofitting or expanding existing lines. Provide detailed specifications on throughput requirements, part dimensions, and integration needs (e.g., ERP/MES connectivity). Reputable vendors will deliver CAD layouts and control architecture proposals within 5–7 business days.

What are common MOQ and payment terms?

MOQ is typically one set or unit, even for large systems. Payment structures usually involve 30–50% upfront deposit, with balance due before shipment. Escrow services are recommended for first-time transactions to ensure delivery compliance and functional validation.