Flexible Production Examples

Top sponsor listing

Top sponsor listing

1/12

1/12

1/11

1/11

1/40

1/40

1/6

1/6

1/24

1/24

1/21

1/21

1/11

1/11

1/24

1/24

1/19

1/19

1/17

1/17

1/17

1/17

1/15

1/15

About flexible production examples

Where to Find Flexible Production Suppliers?

China leads global flexible production manufacturing, with specialized industrial clusters in Guangdong and Henan provinces offering distinct advantages. Shenzhen and Foshan in Guangdong serve as hubs for advanced material engineering and electronics, leveraging proximity to high-tech supply chains and export ports. Henan’s Zhengzhou region focuses on construction-grade flexible materials, supported by regional raw material processing capabilities that reduce input costs by 15–25% compared to international benchmarks.

These regions feature vertically integrated ecosystems where substrate sourcing, coating application, and finishing occur within consolidated facilities. This integration enables rapid prototyping and scalable batch production, with typical lead times of 20–35 days for customized orders. Buyers benefit from localized logistics networks, access to diverse material chemistries (including silicone, ceramic composites, and polymer-based substrates), and established compliance frameworks for EU and North American markets.

How to Choose Flexible Production Suppliers?

Key evaluation criteria should include technical capability, quality assurance systems, and transaction reliability:

Material & Process Expertise

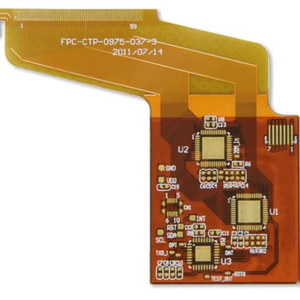

Confirm supplier proficiency in core technologies such as flexible casting, thin-film lamination, or mold transfer processes. For wall cladding and veneers, verify compatibility with substrates like MCM (Modified Clay Material), FRP, or silicone rubber. In PCB applications, assess experience with polyimide films, multi-layer etching, and impedance control.

Quality Management Systems

Prioritize suppliers with documented quality controls, including process validation and batch traceability. While formal ISO 9001 certification is not universally present, consistent on-time delivery rates above 90% and response times under 3 hours indicate operational discipline. For export-bound goods, ensure product testing aligns with destination market requirements (e.g., RoHS for electronics, fire safety standards for building materials).

Customization & Scalability Verification

Evaluate customization depth across parameters such as color, thickness, size, surface texture, and branding. Cross-reference stated minimum order quantities (MOQs) with actual transaction data—suppliers listing MOQs below 50 units typically support low-volume prototyping, while those requiring 500+ square meters cater to large-scale projects. Assess scalability through online revenue indicators and production capacity tags.

What Are the Best Flexible Production Suppliers?

| Company Name | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization Options | Min. Order | Verified Type |

|---|---|---|---|---|---|---|---|---|

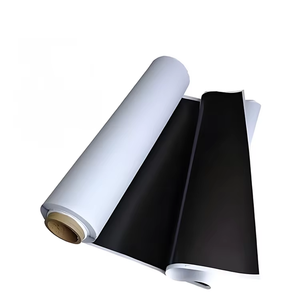

| Shenzhen Brico Import And Export Trade Co., Ltd. | Magnetic Materials, Peel & Stick Wallpapers, Whiteboards | 93% | <15% | ≤1h | US $10,000+ | Color, material, size, logo, packaging, graphic | 10–100 pcs/m² | Custom Manufacturer |

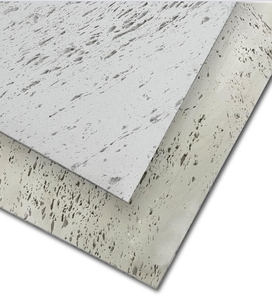

| Henan Htx Group Co., Ltd. | Flexible Stone, Silicone Veneer, Ceramic Tile, Concrete Casting | 90% | 25% | ≤3h | US $10,000+ | Color, thickness, design, material, logo, graphic, lead time | 10–50 pcs | - |

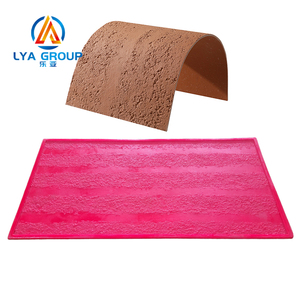

| Zhengzhou Lya Machinery Co., Ltd. | Flexible Clay Cladding, MCM Panels, Silicone Rubber Casting | 100% | <15% | ≤3h | US $50,000+ | Color, material, size, design, logo, packaging, graphic | 100 m²/pieces | - |

| Yuwei Electronic Technology (wuhan) Co., Limited | PCBA, Flexible PCB, HDI & Multilayer Circuits | 85% | 55% | ≤4h | US $320,000+ | Design, layer count, material spec, solder mask, silkscreen | 1 piece | - |

| Foshan Parcos Co., Ltd. | Flexible Stone Veneer, Ceramic Cladding, Marble Panels | 100% | 17% | ≤2h | US $170,000+ | Color, material, size, logo, packaging, label, graphic | 500 m² | Multispecialty Supplier |

Performance Analysis

Zhengzhou Lya Machinery and Foshan Parcos demonstrate perfect on-time delivery records, indicating robust production planning—critical for time-sensitive construction and renovation projects. Yuwei Electronics stands out in electronics manufacturing with a high reorder rate (55%) and ultra-low MOQs (1 piece), reflecting strong customer satisfaction in prototype and small-batch PCB services. Shenzhen Brico offers the fastest average response time (≤1 hour), enhancing communication efficiency for iterative design processes. Suppliers with higher online revenues (>$100K) typically maintain broader inventory and dedicated R&D teams, enabling faster turnaround on complex customizations.

FAQs

How to verify flexible production supplier reliability?

Assess performance metrics including on-time delivery rate (target ≥90%), response speed (ideal ≤3 hours), and reorder rate (lower rates may indicate niche or project-based clients). Request process documentation for critical steps such as demolding, curing, or circuit etching. Conduct virtual factory audits to confirm equipment availability and workflow organization.

What is the typical MOQ for flexible materials?

MOQ varies by material type: electronics (e.g., flexible PCBs) often start at 1 piece; decorative panels range from 100 to 500 square meters. Low-MOQ suppliers accommodate sampling and pilot runs, while bulk-oriented vendors require larger commitments for cost-effective production.

Can flexible production suppliers meet international standards?

Yes, many suppliers adhere to export-grade specifications. For building materials, confirm flame resistance (e.g., ASTM E84) and durability testing. In electronics, validate compliance with IPC-6013 (flexible circuit performance) and RoHS directives. Request test reports or third-party certifications when available.

Do suppliers offer free samples?

Sample policies vary. Some suppliers provide paid samples refundable against future orders, particularly for high-unit-cost items like custom molds or engineered panels. Expect sample fees covering 30–60% of unit cost, with shipping charged separately. Negotiate sample terms before placing initial orders.

How to initiate customization for flexible products?

Submit detailed specifications including dimensions, material preferences, surface finish, color codes (e.g., Pantone or RAL), and functional requirements (e.g., bend radius, temperature resistance). Reputable suppliers will respond with technical feasibility assessments, material recommendations, and estimated tooling lead times within 72 hours.