Flextronics Electronics

CN

CN

1/20

1/20

1/26

1/26

1/26

1/26

1/24

1/24

1/40

1/40

About flextronics electronics

Where to Find Flextronics Electronics Suppliers?

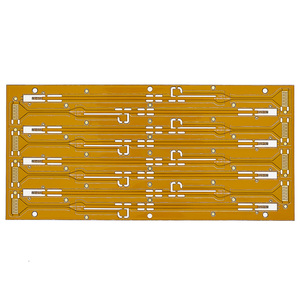

China remains the global epicenter for flextronics electronics manufacturing, with Shenzhen and Guangzhou serving as primary hubs due to their dense ecosystems of component suppliers, contract manufacturers, and logistics networks. These regions host specialized industrial zones focused on flexible printed circuits (FPC), rigid-flex PCBs, and electronic interconnect systems, enabling rapid prototyping and scalable production. Shenzhen alone accounts for over 50% of China’s electronics export volume in this category, supported by advanced polyimide processing facilities and automated assembly lines.

The concentration of technical expertise and vertically integrated supply chains allows for reduced material lead times and lower unit costs—typically 20–35% below Western benchmarks. Most suppliers operate within clusters where raw materials, fabrication tools, and testing labs are accessible within a 30km radius, facilitating faster order fulfillment. Standard lead times range from 10–20 days for sample batches and 25–35 days for mass production, depending on complexity. Buyers benefit from flexible MOQs, often starting at 1–5 pieces for prototypes and scaling to tens of thousands for OEM contracts.

How to Choose Flextronics Electronics Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical & Material Capabilities

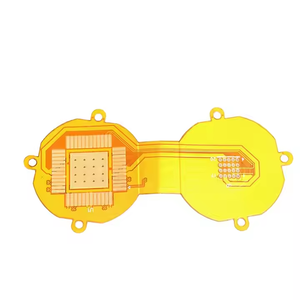

Confirm supplier proficiency in key processes: laser drilling, electroless copper plating, coverlay lamination, and impedance control. Preferred materials include Kapton polyimide and copper foils (1/2 oz to 2 oz thickness). For high-reliability applications (automotive, medical), verify experience with rigid-flex stack-ups and controlled-depth vias. Suppliers should support trace widths/spacing down to 0.075mm and offer impedance tolerance within ±10%.

Quality Management Systems

Prioritize suppliers with documented adherence to IPC-6013 (flexible circuit qualification) and ISO 9001 standards. RoHS and REACH compliance is essential for EU market access. Request test reports for solder peel strength, thermal cycling (−40°C to +85°C), and bend endurance (minimum 10,000 cycles at 1mm radius). In-circuit testing (ICT) and flying probe validation should be standard for batch verification.

Production Scalability & Responsiveness

Evaluate infrastructure indicators:

- Monthly FPC output capacity exceeding 100,000 units

- In-house CAM engineering and DFM feedback within 24 hours

- Average response time under 4 hours and on-time delivery rate ≥98%

Cross-reference performance metrics with reorder rates—suppliers with rates above 50% indicate strong customer retention, while sub-20% suggest niche or transactional engagement models.

Procurement Safeguards

Utilize secure payment terms such as escrow or letter of credit for initial orders. Require sample validation before full production, particularly for custom geometries or impedance-critical designs. Verify authenticity of certifications through third-party databases. Conduct virtual audits via live video tours to confirm cleanroom conditions, ESD-safe workstations, and automated optical inspection (AOI) deployment.

What Are the Best Flextronics Electronics Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen E-Connecting Technology Co., Ltd. | Shenzhen, CN | FPC, Wiring Harness, Connectors | US $120,000+ | 100.0% | ≤1h | <15% | 5–50 pcs | $1–12 |

| Toptek Pcb Co., Limited | Shenzhen, CN | Flexible PCB, Rigid-Flex, OEM Stiffeners | US $1,000+ | 100.0% | ≤1h | 66% | 1 pc | $0.90–5 |

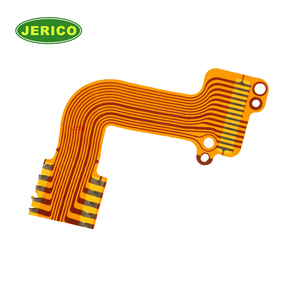

| Shenzhen Syy Technology Co., Ltd. | Shenzhen, CN | Game Console Flex Cables, Repair Parts | US $130,000+ | 100.0% | ≤4h | <15% | 1–6 pcs | $0.29–1.19 |

| Flexkys Elec Tech Co. | Shenzhen, CN | Flex Sensors, Keypads, Level Sensors | US $30,000+ | 100.0% | ≤8h | 17% | 10–100 pcs | $1.70–28 |

| Guangzhou Etoplink Communication Firm | Guangzhou, CN | Mobile Phone Flex Cables, LCD Interconnects | US $70,000+ | 100.0% | ≤9h | 46% | 10 pcs | $0.20–0.60 |

Performance Analysis

Toptek Pcb stands out for low-volume flexibility with 1-piece MOQs and competitive pricing ($0.90/unit), coupled with a high reorder rate (66%), indicating strong satisfaction in OEM and prototyping segments. Shenzhen E-Connecting and Syy Technology report substantial online revenues (>$120K) and perfect on-time delivery, though their low reorder rates suggest transactional buyer behavior, possibly tied to replacement parts markets. Guangzhou Etoplink offers cost-effective solutions for mobile repair sectors with stable pricing at $0.20–0.60 per unit. Flexkys specializes in sensor-based flex circuits, requiring higher MOQs but delivering engineered solutions for industrial monitoring. Buyers seeking rapid iteration should prioritize suppliers with sub-4-hour response times and 1-piece sampling capabilities.

FAQs

How to verify flextronics electronics supplier reliability?

Validate quality systems through ISO 9001 documentation and request sample test reports for continuity, insulation resistance, and thermal shock. Confirm supplier history via transaction volume, response consistency, and delivery performance. Conduct video audits to assess production floor organization and ESD controls.

What is the typical lead time for custom flex circuit samples?

Standard turnaround is 7–12 days for single-layer FPCs and 12–18 days for multilayer or rigid-flex designs. Complex impedance-controlled layouts may require up to 25 days. Air shipping adds 5–7 days for international delivery.

Can suppliers handle RoHS-compliant and lead-free production?

Yes, most established suppliers support lead-free assembly with ENIG or immersion silver finishes and comply with RoHS/REACH directives. Confirm use of halogen-free coverlays and lead-free solder profiles upon order confirmation.

Do suppliers provide free samples?

Sample policies vary. Some suppliers offer paid samples refundable against future orders (e.g., 1–5 units at cost). True free samples are rare; expect to cover material and setup fees, especially for custom tooling.

How to initiate customization for flex circuits?

Submit Gerber files, layer stack-up specifications, bend radius requirements, and impedance targets. Reputable suppliers provide DFM feedback within 24 hours and can generate prototypes within two weeks. Clearly define dynamic vs. static flex applications to ensure appropriate material selection.