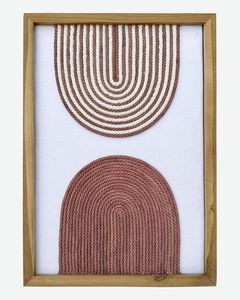

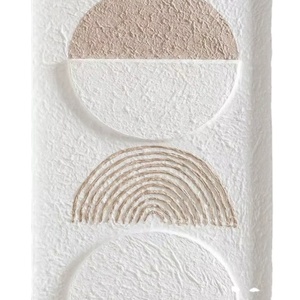

Floating Frame On Canvas

0

0

1/3

1/3

0

0

1/33

1/33

1/3

1/3

1/3

1/3

1/23

1/23

1/3

1/3

1/37

1/37

1/3

1/3

0

0

1/3

1/3

1/25

1/25

0

0

0

0

1/3

1/3

About floating frame on canvas

Where to Find Floating Frame on Canvas Suppliers?

China remains the central hub for floating frame on canvas manufacturing, with key production clusters located in Guangdong, Zhejiang, and Fujian provinces. These regions host vertically integrated supply chains that combine wood processing, canvas stretching, and framing assembly under one ecosystem. Guangdong’s Foshan and Shenzhen zones specialize in premium-grade wooden frames using kiln-dried pine and MDF substrates, achieving moisture resistance ratings below 12%—critical for long-term artwork preservation. Zhejiang's Yiwu and Hangzhou districts focus on high-volume output, supporting monthly production capacities exceeding 500,000 units through automated cutting and edge-banding lines.

The industrial networks enable cost efficiencies of 25–35% compared to Western-based artisans due to localized sourcing of raw materials such as cotton-linen canvas blends, UV-protective coatings, and sustainable timber. Integrated logistics corridors allow direct export via Shenzhen and Ningbo ports, reducing shipping lead times by 7–10 days versus inland manufacturers. Buyers benefit from modular production setups where standard sizes (e.g., 8x10” to 36x48”) are produced in batches, while custom dimensions and deep-profile frames are handled through semi-automated workcells without disrupting throughput.

How to Choose Floating Frame on Canvas Suppliers?

Procurement decisions should be guided by structured evaluation criteria:

Quality Management Standards

Confirm ISO 9001 certification for consistent process control across material inspection, tensioning protocols, and finish application. For EU markets, verify compliance with REACH and RoHS regulations regarding paint and adhesive emissions. Request test reports for colorfastness (minimum ASTM D4236) and frame warp resistance under 48-hour humidity exposure at 75% RH.

Production Capacity Verification

Assess operational scale through measurable indicators:

- Minimum factory footprint of 3,000m² dedicated to framing and stretching lines

- In-house capabilities including CNC routing for frame molding, pneumatic stapling systems, and digital print lamination (if offering giclée-ready surfaces)

- Monthly output capacity exceeding 50,000 units for standard SKUs

Validate claims via facility walkthrough videos highlighting workflow segmentation between mass production and bespoke order zones.

Order Fulfillment Protocols

Require documented MOQs—typically ranging from 50 to 500 pieces depending on customization level—with tiered pricing structures available above 1,000 units. Lead times average 15–25 days for containerized orders, extendable by 7–10 days for non-standard depths (>1.5”). Confirm packaging standards: double-walled export cartons with edge protectors and desiccant packs must be used for ocean freight. Prioritize suppliers offering third-party pre-shipment inspections (e.g., SGS or TÜV) and transparent defect rate tracking (target <1.5%).

What Are the Best Floating Frame on Canvas Suppliers?

No supplier data is currently available for this product category.

Performance Analysis

In the absence of specific supplier profiles, procurement focus should remain on regional strengths. Guangdong-based manufacturers typically offer higher material grades and better finishing consistency, ideal for gallery distributors and luxury home décor brands. Zhejiang suppliers excel in fast turnaround and low-cost replication, making them suitable for promotional art programs or e-commerce drop-shipping models. When engaging new vendors, initiate with small trial runs to evaluate dimensional accuracy (tolerance ±1mm), corner joint integrity, and surface scratch resistance before scaling commitments.

FAQs

How to verify floating frame on canvas supplier reliability?

Audit suppliers through independent quality inspectors who can assess raw material traceability, adhesive curing times, and staple placement density (minimum 3 staples per 4 inches). Review transaction history for repeat buyers and check response consistency across multiple inquiry channels.

What is the average sampling timeline?

Standard samples take 7–12 days to produce, including material preparation and transit. Custom designs requiring unique moldings or canvas treatments may require up to 20 days. Air freight adds 5–8 days depending on destination region.

Can suppliers ship globally?

Yes, most established manufacturers support international shipping via FOB, CIF, or DDP terms. Confirm Incoterms alignment and ensure packaging meets ISPM 15 requirements for wooden components when exporting to Australia, the US, or EU countries.

Do suppliers provide free samples?

Sample policies vary. Many suppliers waive fees for first-time buyers placing future bulk orders (typically 500+ units). Otherwise, expect sample charges covering 40–60% of unit cost, refundable upon order confirmation.

How to initiate customization requests?

Submit detailed specifications including frame profile dimensions, wood species (e.g., basswood, pine, or recycled MDF), canvas weave type (fine/medium/coarse), and desired float gap (standard: 1/4” or 1/2”). Reputable partners will return CAD drawings or physical mockups within 5–7 business days for approval prior to tooling setup.