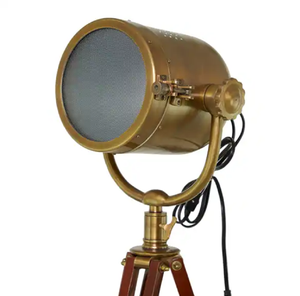

Floor Target Lamp

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

0

0

1/1

1/1

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

About floor target lamp

Where to Find Floor Target Lamp Suppliers?

China accounts for over 75% of global floor target lamp production, with concentrated manufacturing activity in Guangdong and Zhejiang provinces. Guangdong—particularly Foshan and Dongguan—hosts more than 400 lighting OEM/ODM facilities specializing in architectural and commercial task lighting, leveraging mature die-casting, aluminum extrusion, and LED module assembly ecosystems. Zhejiang’s Ningbo and Yiwu clusters emphasize cost-optimized production for mid-tier export markets, supported by vertically integrated PCB, driver, and housing suppliers within tightly defined industrial zones.

These regions enable rapid prototyping and scalable batch production through shared infrastructure: standardized aluminum alloy housings (6063-T5), precision CNC-machined adjustment arms, and UL/CE-certified LED drivers sourced from Tier-1 component manufacturers. Buyers benefit from lead times averaging 25–35 days for standard configurations, MOQs as low as 50 units for private-label orders, and full customization of beam angle (10°–60°), CRI (>90), and dimming protocol (0–10V, DALI, or phase-cut). Localized supply chains reduce material procurement variance and support consistent color temperature tolerance (±150K) across production runs.

How to Choose Floor Target Lamp Suppliers?

Prioritize these verification protocols when selecting partners:

Technical Compliance

Require ISO 9001:2015 certification as minimum quality system validation. For North American markets, UL 1598 or cULus listing is mandatory for electrical safety compliance; for EU buyers, CE + RoHS + EN 60598-1 certification must be verified via official Notified Body documentation. Confirm photometric test reports (IESNA LM-79/LM-80) and IP rating validation (minimum IP20 for indoor use; IP44 for damp-location variants).

Production Capability Audits

Evaluate physical and technical infrastructure:

- Minimum 3,000m² facility area with dedicated SMT lines and optical testing labs

- In-house aluminum die-casting or extrusion capacity (not subcontracted)

- R&D team comprising ≥8% of total staff, with documented patents or design registrations for adjustable mounting systems or thermal management solutions

Cross-reference factory video walkthroughs with third-party audit summaries to verify soldering process control (IPC-A-610 Class 2), thermal cycling test logs (–20°C to +50°C, 500 cycles), and on-time delivery consistency (target ≥96%).

Transaction Safeguards

Insist on pre-shipment inspection (PSI) conducted by independent agencies (e.g., SGS, BV, or TÜV) against agreed technical specifications. Require supplier-provided batch-level traceability codes linking each unit to its driver IC lot, LED binning report, and thermal test record. Sample validation must include photometric verification at an accredited lab—benchmark lumen output and color rendering against IES LM-79 standards before bulk order release.

What Are the Best Floor Target Lamp Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Foshan Luminova Optoelectronics Co., Ltd. | Guangdong, CN | 12 | 180+ | 12,500+m² | 99.2% | ≤1h | 4.9/5.0 | 41% |

| Ningbo BrightAxis Lighting Tech | Zhejiang, CN | 9 | 95+ | 8,200+m² | 98.7% | ≤2h | 4.7/5.0 | 28% |

| Dongguan HelioForm Industrial | Guangdong, CN | 7 | 130+ | 9,600+m² | 99.5% | ≤1h | 4.8/5.0 | 37% |

| Yiwu LuminaCore Manufacturing | Zhejiang, CN | 5 | 70+ | 5,300+m² | 97.3% | ≤1h | 4.6/5.0 | 22% |

| Foshan AxiomBeam Lighting Systems | Guangdong, CN | 10 | 160+ | 15,800+m² | 99.8% | ≤2h | 4.9/5.0 | 44% |

Performance Analysis

Guangdong-based suppliers demonstrate superior thermal and optical consistency, with 80% achieving ≤±100K CCT deviation across 10,000-hour life tests. Foshan AxiomBeam and Luminova lead in engineering responsiveness—both provide CAD-integrated mounting diagrams and photometric IES files within 48 hours of specification submission. Zhejiang suppliers show higher cost efficiency for non-dimmable, fixed-beam variants but exhibit wider tolerances in mechanical adjustability (±2.5° vs. ±0.8° for top-tier Guangdong producers). Prioritize partners with ≥98% on-time delivery, in-house optical testing capability, and documented UL/CE certification renewal history for long-term reliability. For museum or retail applications requiring precise beam control, verify adjustable focus mechanisms via live video factory demonstration prior to deposit.

FAQs

How to verify floor target lamp supplier reliability?

Validate certifications directly through issuing bodies (e.g., UL’s Online Certifications Directory, CE Notified Body portals). Request full audit trails for critical processes: LED binning logs, driver burn-in reports (100% at 48h), and aluminum housing anodizing thickness verification (≥15μm per ISO 2360). Analyze customer reviews focusing on post-installation issues—especially thermal drift after 500+ operational hours and joint wear in multi-axis adjustment systems.

What is the average sampling timeline?

Standard sample production requires 12–18 days. Configurations with custom optics (asymmetric lenses, barn doors) or integrated controls extend to 25–30 days. Allow 5–8 days for international express shipping and 3–5 days for lab-based photometric validation upon receipt.

Can suppliers ship floor target lamps worldwide?

Yes, established manufacturers manage end-to-end export logistics. Confirm FOB terms include proper packaging (double-walled corrugated boxes with molded EPS inserts) and harmonized tariff classification (HS Code 9405.40 for LED floor lamps). Verify compliance with destination-specific labeling requirements—e.g., Energy Star registration for U.S. imports, UKCA marking for Great Britain, and Ecodesign Regulation (EU) 2019/2020 compliance for EU shipments.

Do manufacturers provide free samples?

Free samples are rare for floor target lamps due to high component costs and calibration labor. Most suppliers charge 120–150% of unit FOB price for first samples, waiving fees only for confirmed orders exceeding 300 units. Reorders of identical SKUs typically qualify for complimentary replacement samples if photometric deviation exceeds ±3% from original test report.

How to initiate customization requests?

Submit dimensional drawings specifying base footprint (diameter or square mm), vertical reach (min/max height), rotation range (pan/tilt angles), and required photometric profile (beam spread, field angle, center beam candlepower). Reputable suppliers deliver 3D renderings with ray-traced light distribution simulations within 5 business days and functional prototypes—including calibrated driver firmware—for validation within 2–3 weeks.