Flowchart Maker

1/22

1/22

1/19

1/19

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/14

1/14

0

0

CN

CN

1/19

1/19

0

0

1/2

1/2

1/2

1/2

1/3

1/3

1/2

1/2

1/3

1/3

0

0

1/18

1/18

About flowchart maker

Where to Find Flowchart Maker Suppliers?

The term "flowchart maker" on industrial sourcing platforms primarily refers to automated machinery used in paper and packaging production lines that manage folding, cutting, stacking, and flow wrapping—processes critical for manufacturing structured paper goods such as napkins, tissue boxes, envelopes, and card packaging. The majority of these systems are manufactured in China, with key supplier clusters located in Henan and Zhejiang provinces. These regions host vertically integrated facilities specializing in paper processing automation, offering scalable production capacity and competitive unit pricing.

Suppliers in Henan leverage proximity to raw material hubs and cost-efficient labor pools, enabling lower machine pricing for mid-volume buyers. Meanwhile, coastal manufacturers in Wenzhou and Zhengzhou benefit from advanced CNC fabrication capabilities and streamlined export logistics via Shanghai and Ningbo ports. This regional specialization allows buyers to balance cost against technical sophistication, with lead times typically ranging from 30–60 days depending on customization scope and order size.

How to Choose Flowchart Maker Suppliers?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm that suppliers offer machines aligned with intended output requirements—such as folding speed (measured in units per minute), material compatibility (paper weight, thickness), and precision tolerances. For integration into existing production lines, verify interface standards including voltage (220V/380V), control systems (PLC brands like Siemens or Mitsubishi), and communication protocols (RS485, Ethernet).

Production Infrastructure Assessment

Prioritize suppliers with demonstrable engineering capacity and physical infrastructure:

- Minimum factory area exceeding 3,000m² to support serial production

- In-house design teams capable of customizing machine configurations (e.g., multi-lane folding, inter-fold patterns)

- On-site CNC machining and welding facilities to ensure component consistency

- Proven track record in delivering turnkey solutions, especially for high-speed (>100 m/min) systems

Cross-reference self-reported data with performance metrics such as on-time delivery rates (target ≥97%) and response times (ideally ≤2 hours) to assess operational reliability.

Quality & Transaction Assurance

While formal certifications (ISO 9001, CE) are not consistently declared in available profiles, prioritize suppliers who provide detailed product specifications, test reports, and video evidence of machine operation. Utilize secure payment mechanisms where possible, particularly for first-time transactions. Request sample units or prototype runs to validate performance under real-world conditions before full-scale procurement.

What Are the Best Flowchart Maker Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Wenzhou Henghao Machinery Co., Ltd. | Zhejiang, CN | $200,000+ | 100% | ≤5h | 33% | Yes | $3,500–4,700 | 1 set |

| Henan Young Bamboo Industrial Co., Ltd. | Henan, CN | $260,000+ | 100% | ≤1h | 16% | Yes | $1,500–7,600 | 1 piece |

| Anhui Jujie Automation Technology Co., Ltd. | Anhui, CN | $270,000+ | 97% | ≤1h | <15% | Yes | $90–550 | 1 carton/piece |

| Zhengzhou Miles Tech Company Ltd. | Henan, CN | $1,000,000+ | 92% | ≤3h | <15% | Yes | $2,700–29,900 | 1 set |

| Quanzhou Rainbow Machinery Co., Ltd. | Fujian, CN | - | 100% | ≤5h | - | No (implied) | $15,000–31,000 | 1 set |

Performance Analysis

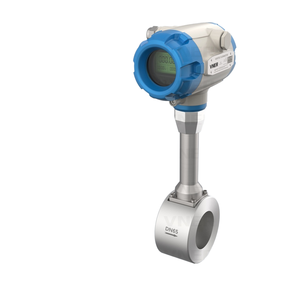

Wenzhou Henghao stands out for consistent on-time delivery and a balanced price-performance ratio, making it suitable for stable mid-tier procurement needs. Henan Young Bamboo offers the lowest entry price point ($1,500) and fastest average response time (≤1h), ideal for small businesses testing automation adoption. Anhui Jujie focuses on liquid flow control subsystems—positioning them as niche providers for auxiliary process automation rather than primary folding equipment.

Zhengzhou Miles Tech commands premium pricing due to advanced features in card and envelope flow wrapping, supported by a large-scale facility and extensive customization capability. Despite a 92% on-time delivery rate, its sub-15% reorder rate suggests potential gaps in post-sale support or long-term reliability. Quanzhou Rainbow targets high-end clients with large-format towel folding systems priced above $30,000, though limited digital transparency may require enhanced due diligence.

FAQs

How to verify flowchart maker supplier reliability?

Validate supplier credibility through documented proof of past shipments, client references, and third-party inspection services. Request factory walkthrough videos focusing on assembly lines and quality control stations. Analyze response consistency and technical depth in communications to gauge engineering support readiness.

What is the typical MOQ and lead time?

Standard minimum order quantities range from 1 piece to 1 set, with most suppliers accommodating single-unit trials. Lead times vary between 20–45 days for standard models; customized systems may require 60+ days depending on complexity and component availability.

Do suppliers offer customization options?

Yes, leading suppliers support modifications in folding pattern, motor power, feeding mechanism, control panel language, and branding (logo, color scheme). Custom tooling may incur additional NRE (non-recurring engineering) fees and extended timelines.

Can flowchart makers be integrated into existing production lines?

Most machines are designed for modular integration with conveyors, stackers, and packaging units. Buyers should confirm input/output dimensions, synchronization signals (I/O ports), and PLC compatibility during specification review.

Are spare parts and technical support available post-purchase?

Supplier policies vary. Some include basic spare kits with initial orders, while others offer remote troubleshooting via video or software diagnostics. Long-term service agreements and on-site technician dispatch are negotiable but often come at additional cost, particularly for non-Chinese markets.