Flowchart Production Process

About flowchart production process

Where to Find Flowchart Production Process Suppliers?

China remains a central hub for integrated production line solutions, with key suppliers specializing in process flowchart-integrated machinery concentrated in Shanghai, Jiangsu, and Jiangxi provinces. These regions host industrial clusters focused on food & beverage processing and mineral extraction systems—two sectors where detailed process flowcharts are critical for turn-key plant deployment. The presence of vertically integrated manufacturing ecosystems enables seamless coordination between engineering design, equipment fabrication, and operational validation.

Suppliers in these zones offer complete process documentation as part of system delivery, ensuring clients receive fully mapped production workflows alongside physical machinery. This integration reduces commissioning time by up to 40% compared to piecemeal sourcing. Proximity to raw material suppliers and port infrastructure supports efficient logistics, with standard lead times ranging from 30 to 60 days depending on complexity. Buyers benefit from consolidated project management, where mechanical systems and procedural blueprints (flowcharts) are co-developed to ensure operational coherence.

How to Choose Flowchart Production Process Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Documentation & System Design

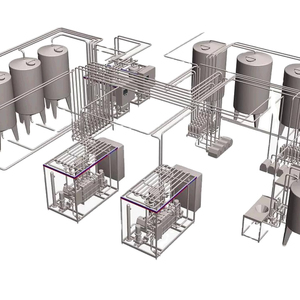

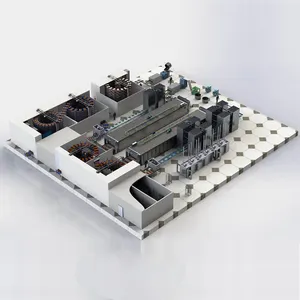

Confirm that suppliers provide comprehensive process flowcharts as part of the quotation package. These should include unit operations, material balances, control points, and inter-machine connectivity diagrams. For food-grade lines, verify compliance with hygiene standards such as 3-A Sanitary Standards or EHEDG certification. In mining applications, assess integration of crushing, separation, and chemical processing stages within the proposed flowchart.

Production Capability Verification

Evaluate supplier infrastructure based on the following criteria:

- Minimum 10,000m² factory area for full-line assembly and testing

- In-house engineering teams capable of generating PFDs (Process Flow Diagrams) and P&IDs (Piping & Instrumentation Diagrams)

- Proven track record in delivering turn-key systems (minimum 5 completed projects in the last 3 years)

Cross-reference delivery performance: prioritize suppliers with ≥90% on-time shipment rates and documented post-installation support.

Transaction Security & Quality Assurance

Utilize secure payment mechanisms such as escrow services tied to milestone verification. Request third-party inspection reports (e.g., SGS, BV) prior to shipment. Conduct virtual or on-site audits to validate equipment build quality and alignment with proposed flowcharts. Sample testing is advised for high-value contracts—benchmark throughput accuracy and energy efficiency against stated specifications before final acceptance.

What Are the Best Flowchart Production Process Suppliers?

| Company Name | Specialization | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Min. Order Value |

|---|---|---|---|---|---|---|---|

| Shanghai Goldcheer Machinery Co., Ltd. | Dairy & Coconut Processing Lines | Food Processing Lines (132) | 100% | ≤10h | Not Available | Not Available | $90,000/set |

| Jiangxi Hengchang Mining Machinery Manufacturing Co., Ltd. | Gold Ore Processing Plants | Custom-Built Mining Systems | 84% | ≤2h | 16% | US $890,000+ | $36,996/set |

| Jiangxi Province County Mining Machinery Factory | Alluvial & Copper Processing | Modular Wash Plants | 100% | ≤4h | 60% | US $150,000+ | $10,000/set |

| Jiangsu Beyond Machinery Co., Ltd. | Plant-Based Milk Production | Dairy & Vegetable Machines (38) | 100% | ≤22h | 100% | US $80,000+ | $49,900/piece |

| Shanghai Qingji Beverage Machinery Co., Ltd. | Dairy & Soy Processing Lines | Dairy Machines (108) | 50% | ≤7h | 50% | US $280,000+ | $300,000/unit |

Performance Analysis

Jiangxi Province County Mining Machinery Factory demonstrates strong customer retention (60% reorder rate) and perfect on-time delivery, indicating robust project execution. Jiangsu Beyond Machinery stands out with a 100% reorder rate, reflecting high client satisfaction in the plant-based beverage sector. While Shanghai Qingji offers high-capacity dairy lines, its 50% on-time delivery rate presents supply chain risk for time-sensitive deployments. Jiangxi Hengchang excels in responsiveness (≤2h average reply time), making it suitable for urgent procurement cycles. Cost-conscious buyers may consider entry-level options starting at $10,000/set, while large-scale processors should target suppliers with proven experience in multi-million dollar turn-key installations.

FAQs

Do suppliers provide process flowcharts with equipment orders?

Yes, reputable suppliers include detailed production process flowcharts as standard deliverables, especially for turn-key systems. These diagrams outline material flow, equipment sequence, control parameters, and safety interlocks.

What is the typical MOQ for production line systems?

Minimum order quantities are typically set at 1 set or unit due to the customized nature of processing lines. Pricing scales with capacity, automation level, and material specifications.

Can flowchart designs be customized for specific facility layouts?

Yes, leading suppliers offer layout-specific adaptations, including space-constrained configurations and integration with existing infrastructure. Customization options often extend to washdown protocols, energy recovery systems, and digital monitoring interfaces.

Are there industry-specific certifications to verify?

For food processing, look for compliance with ISO 22000, HACCP, or FDA design standards. Mining equipment should align with OSHA safety guidelines and environmental discharge regulations. CE marking is commonly provided for electrical and mechanical components.

How long does it take to deploy a full production line?

Lead times range from 45 to 90 days post-design approval. Installation and commissioning add 2–4 weeks, depending on site readiness and complexity. Remote supervision is typically offered during startup phases.