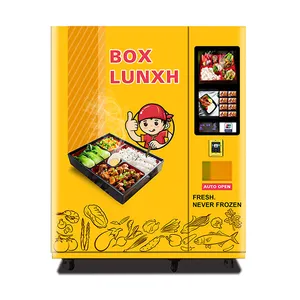

Food Vending Machine With Automatic Heating Producer

1/29

1/29

1/3

1/3

1/10

1/10

1/29

1/29

1/22

1/22

1/3

1/3

1/24

1/24

1/3

1/3

1/15

1/15

1/21

1/21

1/22

1/22

CN

CN

1/41

1/41

CN

CN

1/30

1/30

1/12

1/12

1/3

1/3

1/14

1/14

About food vending machine with automatic heating producer

Where to Find Food Vending Machine with Automatic Heating Producers?

China remains the global epicenter for advanced food vending machine manufacturing, with specialized production clusters in Guangdong, Hunan, and Zhejiang provinces. These regions host vertically integrated facilities capable of full-cycle development—from R&D and sheet metal fabrication to smart system integration and final assembly. Guangdong’s Pearl River Delta region, including Dongguan and Guangzhou, offers mature supply chains for electronics, refrigeration units, and heating systems, enabling rapid prototyping and scalable output. Hunan has emerged as a hub for intelligent vending solutions, supported by local government incentives for IoT and automation innovation.

Manufacturers in these zones typically operate dedicated production lines for heated food vending machines, incorporating microwave or conductive heating modules, dual-temperature compartments, and energy-efficient insulation materials such as polyurethane foam. The concentration of component suppliers—touchscreen panels, bill validators, card readers, cooling compressors—within 50km radii reduces logistics overhead and shortens lead times. Buyers benefit from localized ecosystems that support both high-volume orders and custom engineering, with standard delivery cycles averaging 25–40 days depending on configuration complexity.

How to Choose Food Vending Machine with Automatic Heating Producers?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & System Integration

Verify compliance with international electrical safety standards (IEC 60335) and electromagnetic compatibility (EMC) directives. For markets requiring CE or RoHS certification, request valid test reports from accredited laboratories. Assess software capabilities: leading producers offer cloud-based management platforms supporting remote monitoring, inventory tracking, dynamic pricing, and API integration with third-party payment gateways (e.g., credit cards, mobile wallets). Machines should support multi-language UIs, contactless payments, and optional ID verification for age-restricted items.

Production Capability Assessment

Prioritize manufacturers with end-to-end control over critical subsystems:

- In-house CNC machining and powder coating for structural components

- Dedicated assembly lines for thermal systems (microwave generators, heating trays)

- Integrated testing protocols for temperature consistency, power consumption, and vandal resistance

Confirm minimum facility size of 3,000m² and workforce exceeding 50 personnel, indicating capacity for sustained volume production. Cross-reference self-reported data with verified performance metrics such as on-time delivery rates (>95%) and reorder frequency.

Customization & After-Sales Support

Evaluate flexibility in design modifications: screen size (ranging from 15" to 32"), product compartment layout, power supply compatibility (110V/220V), and environmental adaptations (outdoor/weatherproof models). Ensure vendors provide SDK access for ERP integration and offer firmware updates. Post-delivery support—including spare parts availability, technical documentation, and remote troubleshooting—should be contractually defined prior to order placement.

What Are the Best Food Vending Machine with Automatic Heating Producers?

| Company Name | Location | Verified Status | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Hunan TCN Vending Machine Co., Ltd. | Hunan, CN | Custom Manufacturer | US $3.2M+ | 100% | ≤4h | 50% | 3 sets | $2,929–6,167 |

| Hunan AFEN Vending Machine Co., Ltd. | Hunan, CN | Custom Manufacturer | US $710K+ | 100% | ≤5h | 32% | 1–3 sets | $1,095–5,139 |

| Guangzhou lMT Technology Co., Ltd. | Guangdong, CN | Custom Manufacturer | US $310K+ | 96% | ≤3h | 23% | 1 piece | $4,850–4,966 |

| Hangzhou Jishike Intelligent Technology Co., Ltd. | Zhejiang, CN | Custom Manufacturer | US $170K+ | 86% | ≤7h | <15% | 1 set | $660–5,099 |

| Dongguan Aimir Vending Machine Co., Ltd. | Guangdong, CN | - | - | 100% | ≤3h | - | 1 piece | $1,980–6,950 |

Performance Analysis

Hunan TCN stands out with the highest online revenue and a 50% reorder rate, indicating strong customer retention and satisfaction. All three "Custom Manufacturer"-verified suppliers demonstrate robust technical capabilities, offering extensive customization in tray design, payment systems, language options, and structural configurations (floor-mounted, wall-mounted, outdoor-rated). Guangzhou lMT and Dongguan Aimir allow single-unit MOQs, providing low-risk sampling opportunities. In contrast, Hunan-based producers require minimum batches of 3 units but deliver higher reliability (100% on-time shipment) and deeper engineering support.

Notably, Hangzhou Jishike offers the lowest entry price point ($660) for compact indoor units, though its 86% on-time delivery rate and sub-15% reorder rate suggest potential scalability limitations. Buyers seeking premium-grade commercial deployments should prioritize suppliers with documented experience in API integration, remote diagnostics, and compliance with regional electrical codes.

FAQs

What certifications should food vending machine producers have?

At minimum, suppliers should comply with ISO 9001 for quality management. For export to regulated markets, verify CE marking (EU), FCC (USA), and RoHS compliance. Electrical components must meet IEC 60529 (IP rating for dust/water resistance) and IEC 60335 (household appliance safety).

What is the typical lead time for customized heated food vending machines?

Standard orders take 25–35 days post-deposit. Custom designs involving new molds, unique software interfaces, or dual-heating/cooling systems may extend to 45–60 days. Prototypes are typically available within 20 days upon finalizing specifications.

Can suppliers integrate third-party payment systems?

Yes, most established manufacturers support integration with major payment processors via SDKs. Common integrations include NFC, QR code scanning, EMV-compliant card readers, and SIM-based mobile payments. Confirm compatibility with your target market’s preferred methods before ordering.

Do producers offer white-label or OEM services?

Virtually all listed suppliers provide OEM/ODM support, including custom branding (logos, color schemes), packaging labels, and user interface localization. Minimum order thresholds vary—typically 5–10 units for full white-label treatment.

How to assess build quality before placing an order?

Request factory audit reports, HD video walkthroughs of production lines, and sample units for field testing. Evaluate material thickness (≥1.2mm cold-rolled steel recommended), insulation efficacy, door sealing integrity, and emergency power-off functionality. Third-party inspection services (e.g., SGS, Bureau Veritas) can validate conformance to technical specifications.