Form Cell Formlabs

CN

CN

About form cell formlabs

Where to Find Form Cell and Formlabs Suppliers?

China remains a central hub for manufacturing formwork systems and structural components, with key supplier clusters concentrated in Henan, Shandong, and Qingdao. These regions host vertically integrated production ecosystems specializing in plastic, steel, and aluminum-based form cells used in precast concrete applications. Henan province, particularly Zhengzhou, serves as a logistics and industrial nexus, enabling rapid domestic and international distribution. Shandong’s suppliers benefit from proximity to metal processing facilities, reducing material costs for steel-reinforced and hybrid formwork solutions by up to 20% compared to offshore alternatives.

The regional supply chains support both standardized and engineered-to-order form cell systems. Manufacturers typically operate multi-material production lines—capable of extruding plastic profiles, fabricating steel frames, or laminating composite films—allowing modular design adaptation. Buyers can expect lead times of 15–30 days for standard orders, with scalability supported by facilities averaging 5,000+ m². Customization is widely available across color, panel thickness, joint configuration, and branding, enhancing compatibility with automated construction workflows.

How to Choose Form Cell and Formlabs Suppliers?

Selecting reliable suppliers requires due diligence across technical, operational, and transactional dimensions:

Material & Design Specifications

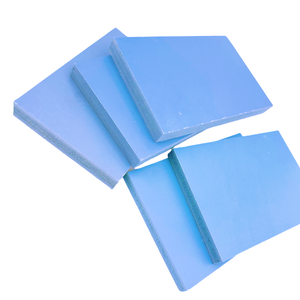

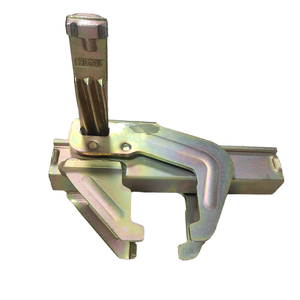

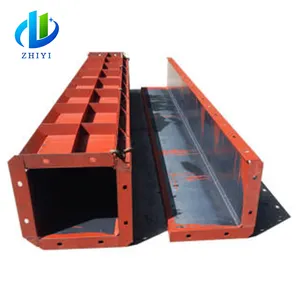

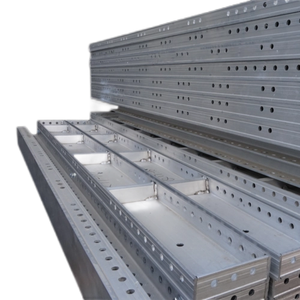

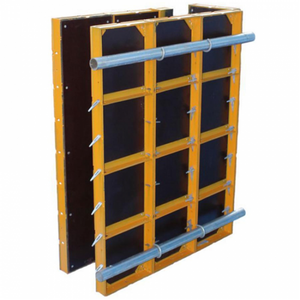

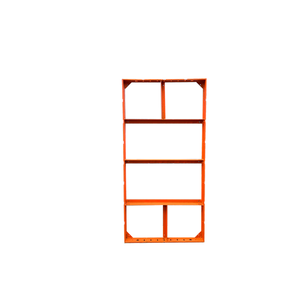

Confirm the base material composition—common options include PP (polypropylene), PVC, galvanized steel, or aluminum-laminated composites—based on durability, reusability, and load-bearing requirements. For high-cycle projects, prioritize plastic formwork with wall thicknesses ≥18mm and UV stabilization. Steel-based systems should feature zinc coating or anti-corrosion treatment for extended service life.

Production and Customization Capacity

Evaluate suppliers based on:

- In-house tooling and molding capabilities for custom panel sizes and interlocking designs

- Available customization parameters: color, logo imprinting, bracing integration, and engineering drawings support

- Minimum Order Quantity (MOQ) flexibility—ranging from 1 piece for plastic modules to 1–2 tons for bulk panels

Quality and Compliance Verification

While ISO 9001 certification is not explicitly stated in all listings, consistent on-time delivery (100% across sampled suppliers) and structured packaging indicate mature quality management practices. Request product test reports for compressive strength, water absorption, and thermal stability. For export compliance, verify adherence to destination-market standards for construction materials, especially where fire resistance or environmental safety is regulated.

What Are the Best Form Cell and Formlabs Suppliers?

| Company Name | Location | Main Materials | Product Range | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Henan Lanke Plastic Profiles Co., Ltd. | Henan, CN | Plastic, Cellular Concrete | Insulated concrete forms, reusable wall panels | 100% | ≤1h | US $20,000+ | <15% | Wall thickness, panel design |

| MTM BUILDING MATERIALS CO.,LTD | Unknown, CN | PVC, Plastic, Metal | Adjustable column formwork, shuttering boards | 100% | ≤3h | US $1,500,000+ | 44% | Color, size, logo, packaging, graphic |

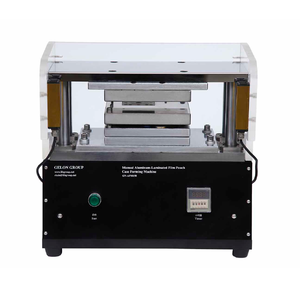

| Shandong Gelon Lib Co., Ltd. | Shandong, CN | Aluminum-laminated film, polymer | Battery film pouches, laminated cases | 100% | ≤3h | US $70,000+ | 17% | Size, material, packaging, labeling |

| Qingdao Qinyuan Steel Co., Ltd. | Qingdao, CN | Steel, Metal | Metal formwork, Euro-form panels, slab systems | 100% | ≤2h | US $1,300,000+ | <15% | Limited customization noted |

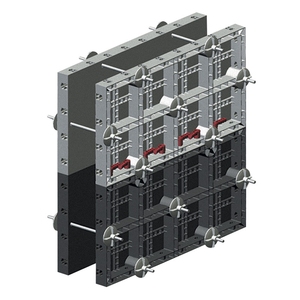

| Zhengzhou Songmao Building Materials Co., Ltd. | Henan, CN | PP Plastic, Reusable Panels | Adjustable molds, plastic formwork, scaffolding | 100% | ≤2h | US $1,400,000+ | 21% | Extensive: size, shape, thickness, bracing, engineering plans |

Performance Analysis

MTM BUILDING MATERIALS and Zhengzhou Songmao lead in customization breadth, supporting tailored formwork configurations critical for complex architectural projects. MTM’s high reorder rate (44%) reflects strong customer retention, likely driven by flexible OEM services and competitive pricing starting at $8 per unit. Songmao offers the most comprehensive engineering adaptability, including mold design, electrical integration, and full assembly documentation. Henan Lanke and Qingdao Qinyuan specialize in material-specific niches—plastic-insulated forms and steel formwork, respectively—making them ideal for buyers prioritizing structural performance over modularity. All top-tier suppliers maintain 100% on-time delivery, with sub-3-hour average response times, indicating robust operational discipline.

FAQs

What are typical MOQs for form cell products?

MOQs vary significantly by material and format. Plastic formwork modules start as low as 1–100 pieces, while bulk panel orders (e.g., cellular concrete) often require 1–2 tons. Battery film pouches and laminated cases are sold per set, with minimums aligned to production batch efficiency.

How long does production and shipping take?

Standard orders are fulfilled within 15–25 days after confirmation. Air freight delivers samples in 7–10 days; sea freight for bulk shipments takes 20–35 days depending on destination port. Expedited production may be available for urgent projects.

Can suppliers provide technical drawings and engineering support?

Yes, advanced suppliers like Zhengzhou Songmao offer full design assistance, including CAD layouts, load calculations, and assembly diagrams. Buyers should request sample drawings during vetting to assess technical capability.

Are free samples available?

Sample availability depends on product value and supplier policy. Low-cost plastic panels may be provided at minimal charge, while high-value items like aluminum-laminated battery films typically require full payment. Sample costs are often credited toward future bulk orders.

What payment and transaction protections exist?

Buyers should utilize secure payment methods such as escrow or letters of credit. Platforms offering trade assurance programs help mitigate risk by linking payment release to shipment verification and quality inspection. Always confirm return policies and dispute resolution mechanisms before order placement.