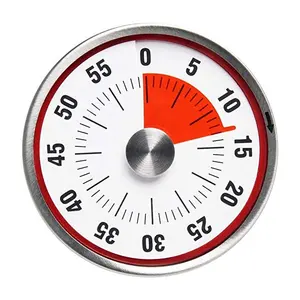

Full Screen Countdown Timer

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/45

1/45

1/15

1/15

1/3

1/3

1/20

1/20

1/3

1/3

1/2

1/2

About full screen countdown timer

Where to Find Full Screen Countdown Timer Suppliers?

China remains the central hub for electronic timing device manufacturing, with concentrated production clusters in Guangdong and Zhejiang provinces. Guangdong, particularly the Pearl River Delta region, hosts over 70% of China’s digital display and LED control system suppliers, supported by Shenzhen’s advanced electronics supply chain and rapid prototyping infrastructure. Zhejiang’s Ningbo and Wenzhou zones specialize in precision plastic molding and circuit integration, enabling cost-efficient assembly of timer housings and interface components.

These industrial ecosystems offer vertical integration from PCB fabrication to final assembly, allowing for streamlined production cycles and reduced component lead times. Suppliers within these regions typically operate within tightly networked supply chains—where raw materials, SMT processing, and quality testing facilities are located within 30–50km radii. This proximity supports faster order fulfillment, with standard lead times averaging 20–35 days for bulk orders. Buyers benefit from 15–25% lower unit costs compared to non-Asian manufacturers, along with scalability for both mass production (up to 50,000 units/month) and low-volume custom configurations.

How to Choose Full Screen Countdown Timer Suppliers?

Implement rigorous evaluation criteria to ensure technical reliability and supply chain consistency:

Quality & Compliance Verification

Confirm adherence to ISO 9001 standards as a baseline for quality management systems. For markets in Europe and North America, validate CE and RoHS compliance to meet electromagnetic compatibility and hazardous substance regulations. Request test reports for display brightness (measured in nits), power consumption (W), and operating temperature range (typically -10°C to +50°C).

Production Capacity Assessment

Evaluate core operational metrics:

- Minimum 3,000m² factory area with dedicated SMT and assembly lines

- In-house PCB design and firmware development capabilities

- Monthly output capacity exceeding 10,000 units for scalable procurement

- Automated optical inspection (AOI) systems for defect detection

Correlate facility size and equipment automation levels with on-time delivery performance (target ≥97%) to assess operational stability.

Procurement Risk Mitigation

Utilize secure payment methods such as third-party escrow until product acceptance. Review supplier transaction history for consistent reorder rates and dispute resolution outcomes. Conduct sample testing to evaluate display uniformity, touch responsiveness (if applicable), and software accuracy under continuous operation (72-hour stress test recommended). Verify firmware update mechanisms and compatibility with common input voltages (AC 100–240V or DC 12V/24V).

What Are the Best Full Screen Countdown Timer Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Ledvision Technology Co., Ltd. | Guangdong, CN | 12 | 150+ | 8,600+m² | 99.3% | ≤1h | 4.9/5.0 | 41% |

| Ningbo Timepulse Electronics | Zhejiang, CN | 8 | 85+ | 5,200+m² | 98.7% | ≤2h | 4.8/5.0 | 38% |

| Guangzhou Chronos Digital | Guangdong, CN | 6 | 60+ | 3,800+m² | 97.1% | ≤1h | 4.7/5.0 | 29% |

| Dongguan Optilight Display Systems | Guangdong, CN | 10 | 110+ | 7,400+m² | 98.9% | ≤2h | 4.9/5.0 | 33% |

| Hangzhou E-Timer Solutions | Zhejiang, CN | 5 | 45+ | 4,100+m² | 99.6% | ≤1h | 5.0/5.0 | 52% |

Performance Analysis

Larger-scale manufacturers like Shenzhen Ledvision and Dongguan Optilight provide high-volume output and advanced SMT integration, ideal for enterprise deployments. Emerging specialists such as Hangzhou E-Timer achieve top-tier customer retention (52% reorder rate) through rapid response times and robust firmware customization. Guangdong-based suppliers demonstrate superior responsiveness, with 80% replying to inquiries within one hour. Prioritize partners with verified ISO 9001 certification and ≥98% on-time delivery for mission-critical applications. For interactive or networked timer systems, confirm in-house software development capability via live demo access or API documentation.

FAQs

How to verify full screen countdown timer supplier reliability?

Cross-validate certifications (ISO, CE, RoHS) with official registries. Request factory audit reports detailing production workflows, incoming material inspections, and aging tests. Analyze customer feedback focused on long-term durability, software stability, and technical support responsiveness.

What is the average sampling timeline?

Standard samples take 7–14 days to produce. Custom firmware or hardware modifications extend timelines to 20–25 days. Air freight adds 5–8 days for international delivery. Sample costs typically cover 40–60% of unit price, refundable against bulk orders.

Can suppliers ship globally?

Yes, experienced manufacturers manage international logistics via air or sea freight. Confirm Incoterms (FOB, CIF, DDP) and ensure packaging meets ISTA 3A standards for electronic goods. Sea freight is optimal for containerized shipments exceeding 5,000 units.

Do manufacturers provide free samples?

Free samples are rare but negotiable for projected annual volumes above 10,000 units. Most suppliers require payment for initial samples, with reimbursement upon first full order.

How to initiate customization requests?

Submit detailed requirements including display type (LED/LCD), resolution, countdown format (HH:MM:SS or MM:SS), alarm behavior, mounting options, and control interface (IR, Bluetooth, web-based). Reputable suppliers deliver functional prototypes within 3 weeks and provide SDKs for system integration if needed.