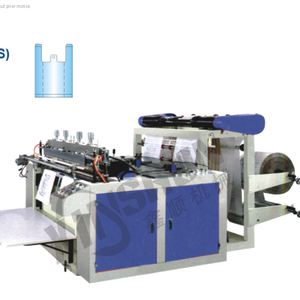

Garbage Bag Machine

CN

CN

Top sponsor listing

Top sponsor listing

About garbage bag machine

Where to Find Garbage Bag Machine Suppliers?

China remains the global epicenter for garbage bag machine manufacturing, with concentrated supplier clusters in Zhejiang, Guangdong, and Jiangsu provinces. These regions host vertically integrated industrial ecosystems that combine polymer processing, precision engineering, and automated assembly. Zhejiang and Guangdong alone account for over 70% of China’s plastic bag machinery exports, supported by mature supply chains for motors, sealing systems, and film extrusion components.

The proximity of raw material suppliers, CNC workshops, and logistics hubs enables streamlined production cycles and rapid prototyping. Facilities in Ruian (Zhejiang) and Dongguan (Guangdong) specialize in high-speed bag-making lines, offering lead times averaging 30–45 days for standard configurations. Localized sourcing reduces component procurement delays by up to 40%, while bulk material access lowers production costs by 15–25% compared to offshore alternatives. Buyers benefit from scalable output—ranging from compact semi-automatic units to fully integrated turnkey lines capable of 600+ bags per minute.

How to Choose Garbage Bag Machine Suppliers?

Procurement decisions should be guided by technical verification, operational transparency, and transactional reliability:

Technical Capabilities & Compliance

Confirm adherence to international safety and quality benchmarks such as CE or ISO 9001. Machines destined for EU or North American markets must comply with electrical safety standards (e.g., IEC 60204) and environmental regulations including RoHS. Request documentation on motor efficiency, thermal sealing accuracy, and control system stability. For biodegradable or specialty film applications, verify compatibility with materials like PLA, PBAT, or PP.

Production Infrastructure Assessment

Evaluate supplier capacity through key indicators:

- Minimum factory area exceeding 3,000m² for stable volume output

- In-house R&D teams focused on automation integration and energy optimization

- On-site testing of core functions: sealing consistency, puncher alignment, roll tension control

Cross-reference online revenue metrics and on-time delivery rates (target ≥95%) to assess operational maturity.

Customization & Transaction Security

Prioritize suppliers offering configurable options in bag dimensions, material thickness (up to 120μm), print registration, and packaging layout. Ensure digital design validation (CAD/3D modeling) is available for custom builds. Utilize secure payment mechanisms such as escrow services, especially for first-time transactions. Conduct pre-shipment inspections via third-party auditors to verify machine performance against agreed specifications.

What Are the Best Garbage Bag Machine Suppliers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Verified Supplier Type |

|---|---|---|---|---|---|---|---|

| Zhejiang Baihao Machinery Co., Ltd. | Bag Making Machines, Blown Film Production Line, Glove Making Machines | Material (PE/PVC), thickness, color, logo, hole punch, sealing type, packaging | 100% | ≤3h | - | US $3,000+ | Custom Manufacturer |

| Shenzhen Huachuanggong Machinery Equipment Co., Ltd. | Injection Molding Machines, Sealing Machines, Multi-Function Packaging Machines | Limited customization reported | 92% | ≤2h | 45% | US $20,000+ | - |

| Dongguan Haidike Automation Equipment Co., Ltd. | Bag Making Machines, Paper Processing Machinery, Cloth Cutting Machines | Heat sealing, cold sealing, PVC film compatibility, liquid bag variants | 100% | ≤7h | 25% | US $20,000+ | - |

| Ruian Win-Win Machinery Co., Ltd. | Automatic T-shirt Bag, Draw-Tape Bag, Heavy-Duty Plastic Bag Machines | Size, color, logo, label, packaging, graphic design | 100% | ≤6h | 18% | US $520,000+ | Multispecialty Supplier |

| Ruian Nuosheng Machine Co., Ltd. | Blown Film Lines, PE Roll Bag Machines, Vest Bag Makers | Film type, width, overlap system, knife configuration | 100% | ≤1h | - | - | - |

Performance Analysis

Zhejiang Baihao and Ruian Nuosheng demonstrate strong operational discipline with perfect on-time delivery records and sub-3-hour response times. Shenzhen Huachuanggong stands out with a high reorder rate (45%), indicating customer satisfaction despite lower delivery performance. Ruian Win-Win leads in revenue scale (US $520,000+), suggesting extensive export activity and capacity for large orders. Dongguan Haidike offers competitive pricing and versatility across heat-sealing technologies, ideal for niche applications like liquid or medical waste bags. Suppliers in Ruian exhibit deep specialization in polyethylene film conversion, while Dongguan-based firms integrate automation for higher throughput.

FAQs

What materials can garbage bag machines process?

Most machines handle LDPE, HDPE, LLDPE, and recycled PE films. Advanced models support biodegradable blends (e.g., cornstarch-based polymers) and laminated PVC. Confirm film width, thickness range (typically 15–120μm), and melt index compatibility with the extruder or feed system.

What is the typical MOQ and lead time?

Minimum order quantity is generally 1 unit for standalone machines. Lead time ranges from 20–45 days depending on automation level and customization. Pre-engineered models ship faster; fully customized lines may require additional validation steps.

Can suppliers provide factory audits or video tours?

Yes, reputable manufacturers offer virtual facility walkthroughs and real-time operation demonstrations. Request footage of live machine testing, component assembly, and quality checks to validate production claims.

Do garbage bag machines support printing and branding?

Many models integrate inline printing systems (up to 6 colors) for logos, warnings, or barcodes. Confirm print cylinder availability, registration accuracy, and ink compatibility (solvent/water-based). Some suppliers partner with flexographic printers for turnkey solutions.

How are machines packaged and shipped internationally?

Machines are crated in seaworthy wooden enclosures with anti-corrosion treatment. FOB terms are common; CIF is available upon request. Full container loads (20ft or 40ft) optimize shipping costs. Buyers should confirm voltage adaptation (380V/50Hz vs. 220V/60Hz) and control panel language options prior to shipment.