Ge Opal 1.0 Nugget Ice Maker

1/8

1/8

1/32

1/32

1/24

1/24

1/18

1/18

1/11

1/11

1/22

1/22

CN

CN

1/21

1/21

1/2

1/2

1/16

1/16

About ge opal 1.0 nugget ice maker

Where to Find GE Opal 1.0 Nugget Ice Maker Suppliers?

China remains the central hub for compact and commercial nugget ice maker production, with key manufacturing clusters in Guangdong, Zhejiang, and Jiangmen offering specialized capabilities. Guangdong-based suppliers leverage proximity to raw material hubs and export ports, enabling streamlined logistics for global buyers. Zhejiang's Ningbo region specializes in small to mid-sized portable units, supported by a dense network of plastic injection molding and compressor component suppliers. Jiangmen has emerged as a center for higher-capacity countertop models, integrating stainless steel fabrication and advanced refrigeration systems.

These industrial zones support vertically integrated production—encompassing sheet metal processing, PCB assembly, foam insulation, and final testing—reducing dependency on external vendors. This integration allows for faster prototyping (7–14 days) and scalable output, with leading factories maintaining monthly production capacities exceeding 10,000 units. Buyers benefit from localized supply chains that reduce unit costs by 20–35% compared to OEMs outside Asia, alongside flexible MOQ structures ranging from 1 to 500+ units depending on model complexity.

How to Choose GE Opal 1.0 Nugget Ice Maker Suppliers?

Procurement decisions should be guided by systematic evaluation criteria:

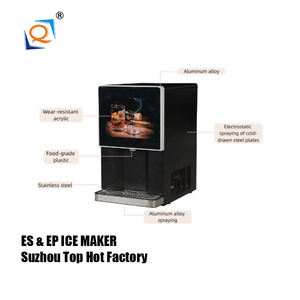

Technical and Quality Compliance

Confirm adherence to international electrical and safety standards such as CE, RoHS, and UL certifications, particularly for North American and European markets. Verify compliance documentation for core components including compressors, condensers, and control boards. Request test reports covering energy consumption (typically 175W–300W), daily ice yield (12–24 kg/24h), and noise levels (≤45 dB).

Production and Customization Capacity

Assess supplier infrastructure based on:

- Minimum factory area of 3,000m² for stable mass production

- In-house design teams capable of modifying color, logo, packaging, and internal sensors

- Plastic shell molding and foam insulation capabilities for thermal efficiency

Cross-reference online revenue data and order fulfillment history; prioritize suppliers with reorder rates above 30% and on-time delivery performance exceeding 96%.

Transaction and Sourcing Security

Utilize secure payment methods with escrow protection, especially for initial orders. Validate supplier responsiveness—target response times under 5 hours—and confirm sample availability. Pre-shipment inspections are recommended to verify build quality, ice texture consistency (chewable nugget form), and cycle timing accuracy.

What Are the Best GE Opal 1.0 Nugget Ice Maker Suppliers?

| Company Name | Location | Main Products | Customization Options | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Guangshen Electric Produce Co., Ltd. | Guangdong, CN | Ice Machines, Refrigeration Equipment | Color, size, logo, packaging | 100% | ≤8h | Not disclosed | - | 1 piece |

| Ningbo Jewin Electrical Appliances Co., Ltd. | Zhejiang, CN | Portable, Home, Commercial Ice Makers | Color, size, logo, packaging, label | 100% | ≤4h | US $5,000+ | <15% | 100–500 pieces |

| Jiangmen Pro-Taylor Refrigeration Co., Ltd. | Jiangmen, CN | Commercial Nugget, Crushed, Chewable Ice Makers | Economy model, capacity, sensor, dual water inlet, logo | 96% | ≤3h | US $140,000+ | 18% | 1 unit |

| Ningbo Aquart Electrical Appliance Co., Ltd. | Zhejiang, CN | Household, Countertop, Nugget Ice Makers | Color, material, size, logo, packaging, graphic | 100% | ≤5h | US $140,000+ | 33% | 455–1000 pieces |

| Guangzhou Itop Kitchen Equipment Co., Ltd. | Guangdong, CN | Commercial Snowflake, Smart Ice Machines | Material, color, logo, packaging, graphic | 98% | ≤4h | US $950,000+ | <15% | 1–50 pieces |

Performance Analysis

Suppliers like Ningbo Aquart and Guangzhou Guangshen demonstrate strong reliability with 100% on-time delivery and extensive customization capabilities, making them suitable for branded or private-label procurement. Jiangmen Pro-Taylor stands out for technical flexibility, offering modifications to water inlet systems and internal sensors—ideal for specialized applications. Guangzhou Itop leads in export volume, reflecting robust logistics management despite higher price points. For low-volume trials, MOQs starting at 1 piece provide entry flexibility, while bulk buyers gain cost advantages at 500+ unit tiers where per-unit pricing drops below $120. Prioritize suppliers with documented quality control processes and proven experience in refrigerant handling (R134a/R600a) for regulatory compliance.

FAQs

How to verify GE Opal 1.0 nugget ice maker supplier credibility?

Review certification claims through third-party verification platforms. Request factory audit reports or video tours confirming production lines and QC checkpoints. Analyze transaction history, focusing on consistent delivery performance and post-sale support responsiveness.

What is the typical lead time for samples and bulk orders?

Sample production takes 7–14 days, with air freight adding 5–10 days for international delivery. Bulk order lead times range from 25–40 days depending on customization level and production load.

Can suppliers replicate GE Opal 1.0 functionality and design?

Manufacturers offer functionally similar models producing chewable nugget ice with comparable yields (15–24 kg/24h) and dimensions. While direct branding replication is restricted, technical specifications and user experience can be closely mirrored under private labeling agreements.

Do suppliers support dropshipping or small-batch shipping?

Some suppliers accept single-unit orders, but shipping costs and import duties must be factored. For e-commerce resellers, partnering with suppliers offering 1-piece MOQs provides inventory testing opportunities before scaling.

What customization options are available for OEM/ODM projects?

Full ODM support includes custom housing colors, control panel graphics, molded logos, packaging design, and capacity adjustments. Advanced modifications such as dual water inlets, smart sensors, or energy-efficient compressors require engineering collaboration and minimum volumes of 1,000+ units.