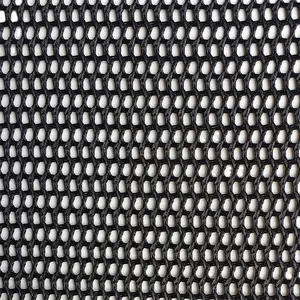

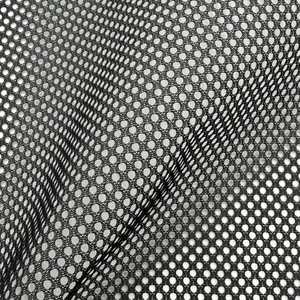

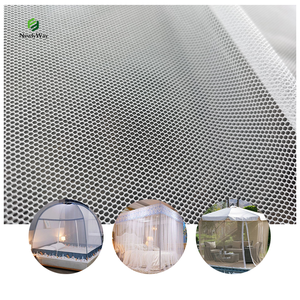

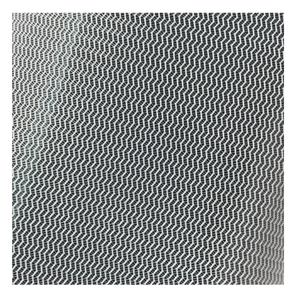

Gi Netting Mesh

About gi netting mesh

Where to Find GI Netting Mesh Suppliers?

China remains the central hub for industrial-grade galvanized iron (GI) netting mesh production, with key manufacturing clusters in Guangdong, Zhejiang, and Fujian provinces. These regions host vertically integrated textile and metal fabrication facilities capable of producing both synthetic mesh fabrics and metallic GI variants used in construction, agriculture, and filtration applications. Shaoxing and Foshan serve as primary textile-processing centers, offering advanced knitting, coating, and finishing lines that support high-volume output of polyester-based mesh materials. Meanwhile, Guangzhou leverages its proximity to raw material suppliers and export ports to streamline logistics for international buyers.

The concentration of technical expertise and supporting infrastructure enables efficient scale-up of customized orders. Suppliers in these zones typically operate within ecosystems where yarn extrusion, weaving/knitting, dyeing, embroidery, and packaging services are available within a 50-kilometer radius. This integration reduces lead times by 20–30% compared to decentralized supply chains. Buyers benefit from competitive pricing—driven by localized polyester and spandex sourcing—and flexible MOQs ranging from 1 meter to 50 kilograms, depending on product type and fabrication complexity.

How to Choose GI Netting Mesh Suppliers?

Evaluate potential partners using the following verification criteria:

Material & Production Capability

Confirm supplier access to core materials such as 100% polyester, nylon, spandex, or galvanized iron wire, depending on application requirements. For fabric-based mesh products, assess knitting and jacquard machinery capacity. Prioritize suppliers listing specialized processes like 3D embroidery, bead integration, tulle stretching, or heat-setting hexagonal patterning. Minimum viable production infrastructure includes automated cutting and sewing lines for finished mesh rolls.

Quality Assurance Metrics

While formal certifications (e.g., ISO 9001) are not explicitly stated in available data, performance indicators provide insight into reliability:

- On-time delivery rates ≥100% indicate consistent operational control

- Response times ≤3 hours reflect strong customer service protocols

- Reorder rates above 20% suggest satisfaction with product quality and transaction experience

- Online revenue exceeding US $1 million signals established market presence

Customization & Transaction Security

Verify customization capabilities including color dyeing, pattern design, sequin/bead application, width adjustment, and labeling. For risk mitigation, prioritize suppliers with documented order histories and transparent pricing structures. Use secure payment methods with milestone-based disbursement, particularly for bulk or custom-developed mesh fabrics. Request physical samples before committing to large volumes to evaluate texture, tensile strength, and finish consistency.

What Are the Best GI Netting Mesh Suppliers?

| Company Name | Main Products | Price Range (Min) | MOQ | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shaoxing Baixiu Knitting Textile Co., Ltd. | Embroidery Fabric, Polyester/Nylon Fabric, Lining, Sequin Fabric | $1.80/yard | 1 yard | 86% | ≤6h | 19% | US $9,000+ | Not specified |

| Shaoxing Oudie Textile Co., Ltd. | Glitter Mesh, Embroidered Polyester, 3D Floral Fabric | $2.00/meter | 1 meter | 100% | ≤3h | 20% | US $10,000+ | Spacing, color, size, pattern, beads, sequins, dyeing |

| Guangzhou Xiuzi International Trade Ltd. | French Mesh Lace, Beaded Lace, Feather-Embedded Fabric | $6.50/yard | 5 yards | 100% | ≤3h | 24% | US $1,700,000+ | Color, material, size, design, logo, packaging, graphic |

| Foshan Dihong Textile Co., Ltd. | Jacquard Mesh, Knitted Polyester, Wide-Width Tulle | $3.90/kg | 50 kg | 100% | ≤1h | 36% | US $30,000+ | Not specified |

| Guangzhou City Haizhu District Shengxiang Accessories Firm | Sequin Lace, Glitter Embroidery, Rice Flower Grid Mesh | $2.80/yard | 10 yards | 100% | ≤8h | 25% | US $1,000+ | Limited data |

Performance Analysis

Foshan Dihong stands out with a 36% reorder rate and sub-hour response time, indicating high buyer retention and operational efficiency, though it operates at higher MOQs (50kg). Guangzhou Xiuzi leads in revenue volume (US $1.7M+) and offers extensive customization, making it suitable for branded or niche-market procurement. Shaoxing Oudie provides low entry barriers with meter-level MOQs and full delivery reliability. Newer entrants like Shengxiang Accessories cater to fashion-oriented markets with sequined and embroidered mesh variants at competitive price points. Buyers seeking industrial-scale supply should prioritize Foshan and Guangzhou-based firms with proven scalability and compliance tracking.

FAQs

What materials are commonly used in GI netting mesh?

The term "GI netting mesh" often refers to galvanized iron wire mesh but is also applied to synthetic textile meshes resembling metallic grids. Common materials include 100% polyester, nylon, spandex blends, and PVC-coated fibers. True GI mesh uses zinc-coated steel wire, while fabric alternatives use knitted or woven polymers for lightweight applications in apparel, curtains, or temporary barriers.

What are typical minimum order quantities?

MOQs vary significantly: fabric suppliers may require as little as 1 meter or yard for sample testing, while bulk textile producers set thresholds at 10–50 yards or 50 kilograms. Industrial-grade suppliers often quote per kilogram or roll length, requiring larger initial commitments for cost-effective production runs.

How long does it take to receive samples?

Sample processing typically takes 5–10 business days after specification confirmation. Shipping via express courier adds 3–7 days internationally. Complex designs involving beadwork or 3D embroidery may extend development to 14 days.

Can suppliers customize mesh size and pattern?

Yes, many suppliers offer adjustable mesh geometry (hexagonal, square, diamond), width (up to 300 cm), and decorative elements such as sequins, floral embroidery, or glitter infusion. Digital design submission is recommended for precise replication.

Are there standard certifications for mesh fabric quality?

While specific certifications are not listed in current supplier profiles, industry-standard benchmarks include ISO 9001 for quality management, OEKO-TEX for harmful substance testing, and ASTM D4851 for dimensional stability in textile meshes. Request test reports for tensile strength, UV resistance, and shrinkage if intended for outdoor or structural use.