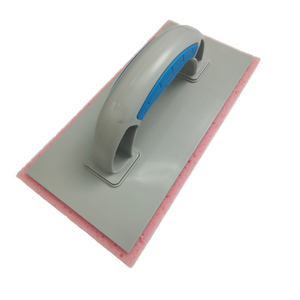

Grout Float

1/26

1/26

1/23

1/23

1/10

1/10

1/19

1/19

1/16

1/16

1/22

1/22

CN

CN

1/42

1/42

1/19

1/19

TW

TW

1/23

1/23

About grout float

Where to Find Grout Float Suppliers?

China remains the dominant manufacturing hub for grout float production, with key suppliers concentrated in industrial regions including Zhejiang, Shandong, and Jiangsu provinces. These clusters benefit from mature supply chains for rubber, EVA foam, and plastic composites—core materials used in grout float construction. Proximity to raw material sources and component manufacturers enables streamlined production cycles and cost efficiencies, with labor and logistics costs averaging 20–35% lower than in Western markets.

Suppliers in these regions operate within vertically integrated ecosystems, supporting both mass production and customized configurations. The availability of skilled tooling and molding specialists within localized networks allows for rapid prototyping and tooling adjustments. Buyers gain access to scalable output capacities, with lead times typically ranging from 15–30 days for standard orders. High-volume producers report monthly outputs exceeding 50,000 units, leveraging automated molding and assembly lines to maintain consistency and throughput.

How to Choose Grout Float Suppliers?

Effective supplier selection requires a structured evaluation of technical capability, quality assurance, and transaction reliability:

Material & Production Expertise

Verify supplier proficiency in working with primary grout float materials: molded rubber (urethane or natural), EVA foam, and composite sponges. Confirm access to compression molding, die-cutting, and handle insertion equipment. Suppliers offering replaceable pad systems or ergonomic designs should demonstrate in-house design validation processes.

Quality Management Systems

While formal certifications such as ISO 9001 are not universally present among smaller exporters, prioritize suppliers with documented quality control procedures. Assess on-time delivery performance (target ≥94%) and reorder rates (indicative of customer satisfaction). Response time under 6 hours is typical among high-service providers and reflects operational responsiveness.

Customization & Compliance

Most leading suppliers support OEM/ODM services, including color variation (red, black, green, blue), size specification (4"x9", 6"x12", etc.), logo imprinting, and packaging design. For export to regulated markets, confirm compliance with REACH, RoHS, or CPSIA standards where applicable, particularly for products intended for consumer retail.

Transaction Verification

Evaluate online revenue indicators and order history as proxies for market presence. Cross-reference product listings with minimum order quantities (MOQs) and pricing structures. Use sample testing to validate material durability, edge finish, and handle adhesion before scaling procurement. Escrow-based payment terms provide financial protection during initial engagements.

What Are the Best Grout Float Suppliers?

| Company Name | Main Materials | Customization Options | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Chevalierous Co., Ltd. | Rubber, Plastic | Not specified | $80,000+ | 100% | ≤5h | 20% | 100 sets | $2–3 |

| Yangzhou Dingyue Plastic Electronics Co., Ltd. | EVA, Sponge, Rubber | Color, size, logo, packaging | $250,000+ | 100% | ≤2h | <15% | 2 pieces | $1.55–9.45 |

| Shanghai Vinon Tools Industrial Co., Ltd. | Urethane, EVA, Rubber | Color, size, logo, packaging | $9,000+ | 100% | ≤11h | 25% | 30 pieces | $1.14–70 |

| Zhangzhou Builder Hardware Co., Ltd. | Rubber, Foam | Color, size, logo, packaging | $30,000+ | 100% | ≤2h | 20% | 48 pieces | $8.45–15.74 |

| Shandong Best Import & Export Co., Ltd. | Rubber, Sponge, EVA | Color, size, logo, packaging | $170,000+ | 94% | ≤6h | 16% | 1,200 pieces | $0.30–1.60 |

Performance Analysis

Yangzhou Dingyue Plastic Electronics stands out for low MOQ flexibility (as low as 2 pieces) and rapid response times (≤2h), making it suitable for small-batch buyers and testing phases. Shandong Best offers the lowest unit pricing ($0.30 at scale), ideal for bulk procurement, though its 94% on-time delivery rate presents marginal risk. Shanghai Vinon demonstrates strong customer retention (25% reorder rate) despite higher price variability, suggesting product quality consistency. Chevalierous and Zhangzhou Builder maintain reliable fulfillment records with mid-range MOQs, catering to established distributors. Buyers seeking full customization should prioritize suppliers with verified design and packaging capabilities, confirmed through direct communication and sample evaluation.

FAQs

How to verify grout float supplier reliability?

Assess on-time delivery history, reorder rates, and response times as operational KPIs. Request product samples to evaluate material density, edge sealing, and handle bonding. Confirm whether the supplier owns molding tools or outsources production, as in-house tooling indicates greater control over quality and lead times.

What is the typical MOQ for grout floats?

MOQs vary significantly by supplier and material. Entry-level MOQs start at 2 pieces for combo kits, while standard rubber or EVA floats require 30–1,200 pieces per order. High-volume producers may set MOQs at 3,000+ units for base models. Negotiation below standard MOQ is possible with adjusted pricing.

Can grout float suppliers provide custom branding?

Yes, most suppliers listed offer OEM services including custom colors, laser logos, branded packaging, and instruction cards. Minimum branding MOQs typically start at 1,000 units, though some accept lower volumes at premium rates.

What are common grout float materials?

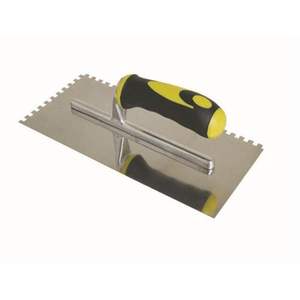

The most widely used materials are molded rubber (durable, consistent pressure), EVA foam (lightweight, cost-effective), and sponge-rubber composites (absorbent, smooth finish). Urethane variants offer extended lifespan in professional applications. Material choice impacts pricing, performance, and suitability for tile type (ceramic, porcelain, stone).

How long does production and shipping take?

Production lead time ranges from 15–25 days after sample approval. Air freight delivers samples in 5–10 days; sea freight for bulk orders takes 25–40 days depending on destination. Expedited production (7–10 days) is available from select suppliers at additional cost.