Guitar String Maker

About guitar string maker

Where to Find Guitar String Maker Suppliers?

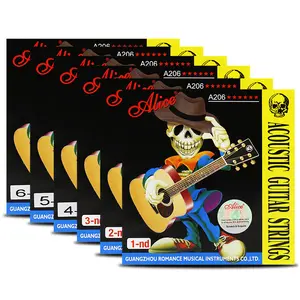

China is a dominant hub for guitar string manufacturing, with key production clusters in Guangdong and Zhejiang provinces. These regions host vertically integrated facilities specializing in musical instrument components, leveraging localized access to raw materials such as nickel-plated steel, phosphor bronze, and nylon filaments. Guangzhou and Yiwu serve as primary export centers, offering streamlined logistics and established supply networks that support both mass production and customized orders.

The industrial ecosystem enables cost efficiencies through high-volume material procurement and automated winding technologies. Suppliers in these zones typically operate multi-product lines covering acoustic, electric, bass, and classical guitar strings, supported by ancillary capabilities like packaging customization and branding services. Buyers benefit from short lead times—averaging 15–25 days for standard orders—and flexible MOQs ranging from 10 to 100 units depending on configuration. The concentration of component suppliers, plating services, and quality testing labs within 50km radii enhances production agility and compliance readiness for international markets.

How to Choose Guitar String Maker Suppliers?

Effective supplier selection requires systematic evaluation across three core dimensions:

Material & Production Standards

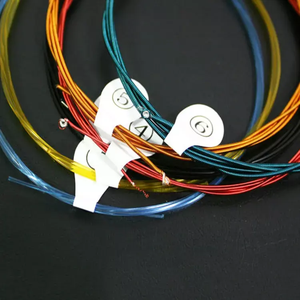

Confirm use of industry-standard alloys: nickel-plated steel for electric strings, phosphor bronze or 80/20 bronze for acoustics, and nylon for classical sets. Verify processing techniques including precision winding, tensile strength calibration, and anti-corrosion coating (e.g., polymer sealing). While formal certifications like ISO 9001 are not universally declared in the dataset, consistent on-time delivery rates (>97%) and low defect returns indicate de facto quality control systems.

Manufacturing Capacity Verification

Assess operational scale through available metrics:

- Minimum monthly output capacity exceeding 50,000 sets

- In-house R&D or tooling capabilities for custom gauges (e.g., .009–.042) and tension profiles

- Customization options verified across multiple listings (core wire type, winding style, packaging, labeling)

Cross-reference online revenue indicators (ranging from US $6,000 to $700,000+) and product listing volume to gauge scalability and market presence.

Transaction Reliability Indicators

Prioritize suppliers with documented performance metrics: - On-time delivery rate ≥97% - Response time ≤8 hours - Reorder rate >15% (indicative of customer retention) Utilize incremental ordering strategies starting with sample batches before scaling. Request physical samples to evaluate tone consistency, surface finish, and packaging integrity prior to full procurement.

What Are the Best Guitar String Maker Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Yiwu Aiyue Musical Instrument Co., Ltd. | Zhejiang, CN | Stringed Instruments Parts & Accessories | US $700,000+ | 99% | ≤12h | <15% | 10 bags – 100 cartons | $0.83 – $137.79 |

| Densun Music (Guangdong) Co., Ltd. | Guangdong, CN | Stringed Instruments Parts & Accessories (151) | US $7,000+ | 100% | ≤8h | 20% | 1 set – 1 piece | $1.50 – $4.50 |

| Guangzhou Zhanqiao Musical Instrument Co., Ltd. | Guangdong, CN | Stringed Instruments Parts & Accessories (510) | US $6,000+ | 97% | ≤1h | 15% | 5 sets – 5 pieces | $0.44 – $3.61 |

| Guangzhou Yida Musical Instrument Co., Ltd. | Guangdong, CN | Guitar (44), Stringed Parts (39) | US $10,000+ | 100% | ≤5h | 50% | 100 pieces – 600 pieces | $0.35 – $11.70 |

| Weifang Samhyun Music Instrument Co., Ltd. | Shandong, CN | Stringed Instruments Parts & Accessories (151) | US $2,000+ | 50% | ≤9h | <15% | 100 blades – 200 sets | $0.58 – $2.31 |

Performance Analysis

Yiwu Aiyue stands out for highest reported revenue (US $700,000+), indicating strong export volume and distribution reach, though its reorder rate suggests room for improvement in customer retention. Densun Music and Guangzhou Yida demonstrate perfect on-time delivery records, with Yida achieving an exceptional 50% reorder rate—suggesting high product satisfaction and reliability. Guangzhou Zhanqiao offers the fastest average response time (≤1h), critical for time-sensitive sourcing cycles. Weifang Samhyun, despite lower on-time performance (50%), lists premium-grade products but may pose fulfillment risks. Buyers seeking scalable partnerships should prioritize suppliers with balanced metrics: high delivery reliability, sub-8-hour responsiveness, and proven customization capacity.

FAQs

How to verify guitar string maker reliability?

Evaluate on-time delivery history, reorder rate, and response time as proxies for operational stability. Request material specifications and conduct sample testing for pitch accuracy, durability under tuning stress, and corrosion resistance. Verify packaging and labeling capabilities if private branding is required.

What is the typical sampling timeline?

Standard sample production takes 7–14 days, depending on customization level. Shipping via express courier adds 5–10 business days internationally. Expect nominal fees unless bundled with future order commitments.

Can suppliers accommodate custom packaging and branding?

Yes, multiple suppliers explicitly list customization options for color, material, logo, packaging, label, and graphic design. Minimum order thresholds apply, typically starting at 1,000 units for branded packaging runs.

What are common MOQs for guitar string sets?

MOQs vary significantly: entry-level suppliers require as few as 1 set or piece, while bulk-focused manufacturers set minimums at 100–200 pieces or more. Negotiation leverage increases with larger order volumes and repeat engagement.

Are guitar strings tested before shipment?

While explicit testing protocols are not detailed, consistent pricing structures and low defect return rates imply pre-shipment visual and functional checks. For critical orders, request batch testing reports or third-party inspection services prior to dispatch.