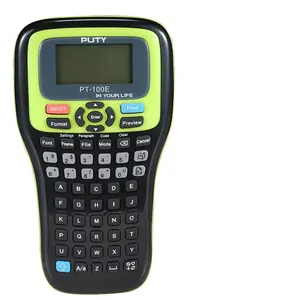

Handheld Label Maker

Top sponsor listing

Top sponsor listing

1/10

1/10

1/22

1/22

1/7

1/7

1/10

1/10

1/12

1/12

About handheld label maker

Where to Find Handheld Label Maker Suppliers?

China remains the dominant hub for handheld label maker production, with key manufacturing clusters concentrated in Fujian, Jiangsu, Guangdong, and Hunan provinces. These regions host vertically integrated supply chains that combine electronics assembly, plastic injection molding, and thermal printing technology under one ecosystem. Xiamen and Suzhou serve as primary export centers due to proximity to major ports and robust infrastructure supporting rapid order fulfillment.

The industrial clusters enable economies of scale, reducing component procurement costs by 15–25% compared to non-specialized regions. Suppliers benefit from localized access to PCB manufacturers, battery producers, and ribbon/tape material suppliers within a 50km radius, ensuring stable material flow and minimizing lead time variability. Most facilities operate automated SMT lines for circuit board production and maintain in-house tooling capabilities for custom housing designs, allowing efficient handling of both standard and customized orders.

How to Choose Handheld Label Maker Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Quality & Compliance Verification

Confirm adherence to international standards such as CE, RoHS, and FCC for electronic safety and environmental compliance—critical for market entry in Europe and North America. While ISO 9001 certification is not universally listed, prioritize suppliers demonstrating structured quality control through documented testing procedures for print head durability, battery performance, and software stability.

Production Capacity Assessment

Evaluate scalability using verifiable metrics:

- On-time delivery rate exceeding 95% (ideal: 100%)

- Response time under 2 hours for inquiry resolution

- Reorder rate below 25% indicates balanced customer satisfaction and competitive pricing

- Monthly online revenue above US $100,000 suggests consistent output and market demand absorption

Cross-reference supplier claims with available transaction data. Facilities offering customization should have dedicated design teams capable of modifying casing color, label width (6mm–12mm), font libraries, connectivity options (Bluetooth/USB), and packaging configurations.

Sourcing Risk Mitigation

Utilize secure payment mechanisms such as trade assurance or escrow services until product acceptance. Request functional samples to validate print clarity, adhesive consistency, and device ergonomics prior to bulk ordering. Verify compatibility with common label tape materials (e.g., laminated polyester, vinyl) and assess firmware usability for text formatting and symbol integration.

What Are the Best Handheld Label Maker Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Xiamen Aiyin Technology Co., Ltd. | Fujian, CN | Thermal Printers, Inkjet Printers, Packaging Labels | US $170,000+ | 98% | ≤2h | <15% | Color, material, size, logo, packaging, graphic |

| Suzhou Qiji Electric Co., Ltd. | Jiangsu, CN | Thermal Printers, Scanners, Printer Supplies | US $420,000+ | 100% | ≤2h | 19% | Not specified |

| Shenzhen Datolink Technology Co., Ltd. | Guangdong, CN | Handheld Label Printers, Portable Printing Machines | US $40,000+ | 92% | ≤2h | 21% | Color, material, size, logo, packaging, label graphic |

| Nanjing Future Fiber Solutions Co., Ltd. | Jiangsu, CN | Fiber Optic Equipment, Telecom Power, Label Makers | US $80,000+ | 100% | ≤2h | 26% | Not specified |

| Hunan Pon Information Technology Co., Ltd. | Hunan, CN | Fiber Optic Equipment, Communication Cables, Label Makers | US $150,000+ | 100% | ≤1h | <15% | Not specified |

Performance Analysis

Suzhou Qiji leads in sales volume with over US $420,000 in reported online revenue and perfect on-time delivery, indicating strong logistics execution. Xiamen Aiyin and Hunan Pon stand out for low reorder rates (<15%), suggesting competitive pricing or effective first-time quality control despite lower repeat purchase behavior. Hunan Pon also offers the fastest average response time (≤1h), enhancing communication efficiency for time-sensitive negotiations.

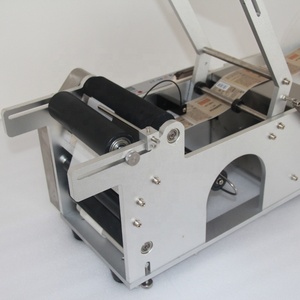

Suppliers like Shenzhen Datolink explicitly promote customization capabilities across multiple parameters, making them suitable for buyers requiring private labeling or specialized form factors. In contrast, Nanjing Future Fiber Solutions focuses on Dymo-compatible models, positioning itself in the replacement and aftermarket segment. Buyers seeking multifunctional devices with rechargeable batteries and wireless connectivity should verify firmware features and Bluetooth protocol support during sampling.

FAQs

What are typical MOQs for handheld label makers?

Most suppliers list minimum order quantities of 1 unit for sample testing, with no enforced MOQ for small purchases. Bulk pricing typically applies at 50+ units, though exact thresholds vary by model and customization level.

What is the average lead time for production?

Standard orders without customization generally ship within 7–15 days after payment confirmation. Customized units involving logo printing or housing modifications may require 15–25 days depending on complexity.

Can suppliers provide OEM/ODM services?

Yes, select manufacturers offer full OEM/ODM support including PCB redesign, software interface localization, and branded packaging. Suppliers with stated customization options (e.g., Xiamen Aiyin, Shenzhen Datolink) are better positioned to handle tailored development projects.

Are handheld label makers compatible with global voltage standards?

Most models use USB-powered rechargeable lithium-ion batteries, making them inherently compatible with 100–240V input via standard adapters. Always confirm charging specifications to ensure compliance with local electrical regulations.

How to evaluate print quality before ordering?

Request sample labels showing text sharpness, barcode readability (tested with commercial scanners), and resistance to smudging or fading. Assess tape width options (commonly 6mm, 9mm, 12mm) and compatibility with outdoor-grade or heat-resistant materials if required for industrial use.