Hook And Loop Cinch Straps Supplier

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/35

1/35

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

1/10

1/10

1/32

1/32

1/25

1/25

1/31

1/31

1/3

1/3

1/3

1/3

1/16

1/16

1/3

1/3

1/3

1/3

1/3

1/3

About hook and loop cinch straps supplier

Where to Find Hook and Loop Cinch Straps Suppliers?

China remains the global hub for hook and loop cinch straps manufacturing, with key production clusters in Guangdong Province—particularly Shenzhen and Foshan—driving supply chain efficiency. These regions host vertically integrated textile and fastening component facilities, enabling rapid prototyping and high-volume output. Shenzhen’s advanced logistics infrastructure supports export-oriented suppliers, while Foshan’s established textile industry provides access to specialized weaving, dyeing, and lamination capabilities critical for durable hook and loop materials.

Suppliers in this ecosystem typically operate multi-line production setups combining nylon webbing extrusion, hook-and-loop pile attachment, heat-sealing, and cutting/packaging automation. This integration allows lead times as short as 7–15 days for standard orders and facilitates cost advantages of 20–35% compared to Western or Southeast Asian producers. Buyers benefit from localized access to raw materials (e.g., polyamide, polyester, and thermoplastic elastomers) and ancillary services such as custom labeling, color matching, and private branding—all within tightly coordinated industrial zones.

How to Choose Hook and Loop Cinch Straps Suppliers?

Evaluating suppliers requires a structured assessment across three core dimensions:

Production & Customization Capability

Confirm suppliers can support required material specifications (e.g., tensile strength, UV resistance, flame retardancy) and dimensional tolerances. Key indicators include in-house loom capacity, dyeing consistency control, and die-cutting precision. Suppliers offering customization should provide options for length (typically 6" to 48"), width (¼” to 2”), color (Pantone matching), logo imprinting, and packaging configuration. Minimum order quantities (MOQs) range from 100 to 1,000 pieces depending on complexity.

Quality Assurance & Compliance

Prioritize suppliers demonstrating adherence to international quality benchmarks. While formal ISO 9001 certification is not universally listed, operational metrics such as on-time delivery rates (target ≥95%) and reorder rates (>20%) serve as proxy indicators of reliability. Materials should comply with RoHS and REACH standards for restricted substances, especially for consumer-facing or outdoor applications. Request sample testing for peel strength, shear resistance, and cycle durability (typically 1,000+ engage/disengage cycles).

Transaction Performance & Responsiveness

Analyze response time (ideally ≤3 hours), historical on-time delivery performance, and online transaction volume as indicators of operational maturity. High-performing suppliers maintain dedicated export teams and offer third-party inspection coordination. Favor partners with transparent communication, documented QC processes, and scalable packaging solutions for retail, industrial, or e-commerce fulfillment.

What Are the Best Hook and Loop Cinch Straps Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Sample MOQ |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Haowell Hook & Loop Co.,Ltd | Shenzhen, CN | Hook & Loop Tapes (272), Cable Ties (144) | US $30,000+ | 100% | ≤1h | 15% | Color, material, size, logo, packaging, label, graphic | 100–500 pcs |

| Foshan CCH Textile Co., Ltd. | Foshan, CN | Hook & Loop Tapes (188), Cable Ties (11) | US $150,000+ | 100% | ≤7h | 25% | Size, color, logo, adjustable design | 100–1,000 pcs |

| TDS INDUSTRIAL COMPANY LIMITED | Unknown, CN | Hook & Loop Tapes (218), Cable Ties (53) | US $20,000+ | 83% | ≤7h | <15% | Logo, color, size, ribbon strength | 100–200 pcs |

| Shen Zhen Happitoo Textile Co., Ltd. | Shenzhen, CN | Hook & Loop Tapes (69), Patches (7) | US $3,000+ | 33% | ≤5h | <15% | Limited customization | 100–500 pcs |

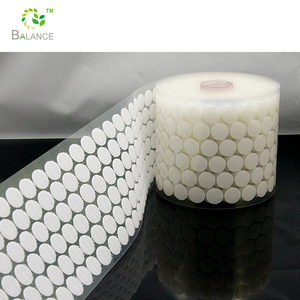

| Shenzhen Sunnice Textile Co., Limited | Shenzhen, CN | Hook & Loop Tapes (126), Plastic Film (35) | US $90,000+ | 95% | ≤3h | <15% | Elasticity, buckle type, stretch band, heavy-duty variants | 200–1,000 pcs |

Performance Analysis

Foshan CCH Textile stands out with the highest reported online revenue (US $150,000+) and a strong 25% reorder rate, indicating consistent buyer satisfaction and reliable fulfillment. Shenzhen Haowell matches top-tier on-time delivery (100%) with the fastest average response time (≤1 hour), making it ideal for time-sensitive procurement. Shenzhen Sunnice combines solid delivery performance (95%) with broad product adaptability, particularly in elastic and heavy-duty strap designs. In contrast, Shen Zhen Happitoo's low on-time delivery rate (33%) presents significant fulfillment risk despite competitive pricing. TDS INDUSTRIAL offers mid-range capability but lacks strong reorder metrics, suggesting potential gaps in post-sale consistency.

FAQs

What are typical MOQs for hook and loop cinch straps?

Minimum order quantities vary by supplier and customization level, ranging from 100 pieces for basic configurations to 1,000 units for bulk or fully branded runs. Some suppliers offer lower MOQs for initial sampling or trial orders.

How long do production and shipping take?

Standard production lead time is 7–15 days after sample approval. Air freight adds 5–10 days for international delivery, while sea shipping takes 25–40 days depending on destination. Expedited processing (3–5 days) may be available for urgent orders at additional cost.

Can suppliers provide free samples?

Most suppliers offer physical samples for evaluation, often at reduced or waived cost if a subsequent order is placed. Expect to pay nominal fees (or freight charges) for prototype or customized samples, typically reimbursable against future purchases.

What materials are used in hook and loop cinch straps?

Primary materials include nylon 6,6 and polyester for high tensile strength and abrasion resistance. Hooks are typically molded polypropylene or nylon, while loops use napped fabric. Industrial-grade versions may incorporate steel-reinforced webbing or neoprene padding for enhanced durability.

Are eco-friendly or recyclable options available?

Some suppliers offer RoHS-compliant, lead-free, and phthalate-free materials. Recycled nylon-based straps are emerging, though availability depends on specific manufacturers. Buyers seeking sustainable sourcing should explicitly request environmental compliance documentation during vetting.