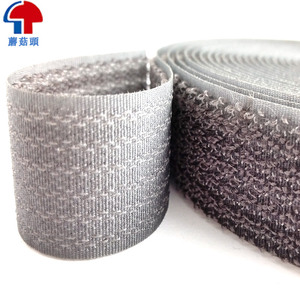

Hook And Loop Tape Manufacturer

0

0

1/22

1/22

0

0

1/3

1/3

1/3

1/3

1/22

1/22

1/3

1/3

1/3

1/3

1/16

1/16

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

1/29

1/29

1/3

1/3

1/3

1/3

1/32

1/32

1/32

1/32

1/3

1/3

About hook and loop tape manufacturer

Where to Find Hook and Loop Tape Manufacturers?

China remains the dominant hub for hook and loop tape manufacturing, with key production clusters concentrated in Guangdong and Fujian provinces. Shenzhen and Dongguan serve as primary industrial centers, hosting vertically integrated textile and fastening material facilities that combine weaving, coating, slitting, and adhesive application under one roof. These regions benefit from mature supply chains for nylon 6.6, polyester backing, and acrylic adhesives—reducing component lead times by 20–30% compared to offshore alternatives.

Manufacturers in this ecosystem typically operate semi-automated production lines capable of extruding hook and loop profiles, applying pressure-sensitive adhesives (PSA), and die-cutting custom widths from 10mm to 100mm. Monthly output capacity among mid-tier suppliers ranges from 500,000 to over 2 million meters, supporting both bulk distribution and engineered-to-order specifications. The proximity of raw material suppliers and logistics hubs enables standard order fulfillment within 15–25 days, with air or sea freight options for global export.

How to Choose Hook and Loop Tape Suppliers?

Effective supplier selection requires systematic evaluation across three core dimensions:

Material & Performance Specifications

Confirm base material composition: high-performance tapes use 100% nylon for superior tensile strength and cycle durability (≥5,000 engage/disengage cycles). Adhesive type should be specified—acrylic for temperature resistance (up to 150°C), rubber-based for immediate tack. Request peel adhesion values (typically 4–8 N/cm) and shear strength data. For eco-sensitive applications, verify RoHS or OEKO-TEX compliance.

Production Flexibility and Minimum Order Quantities (MOQ)

Assess customization capabilities including width, backing (fabric, film, foam), adhesive placement (single/double-sided, back-to-back), and color matching (Pantone standards). MOQs vary significantly:

- Bulk rolls: 500–1,000 meters for standard configurations

- Prototypes/samples: As low as 2–5 meters for testing

- Custom tooling (e.g., specialty hooks): May require 10,000+ meter commitments

Cross-reference listed product pricing—ranging from $0.04/meter for basic non-adhesive strips to $0.50+/meter for reinforced or wide-format tapes—to benchmark competitiveness.

Operational Reliability Indicators

Prioritize suppliers demonstrating consistent on-time delivery (>90%), sub-5-hour average response time, and verifiable reorder rates (>20%). High reorder rates suggest customer satisfaction with quality consistency and service reliability. While formal ISO 9001 certification is not universally declared, evidence of structured QA processes—such as batch testing logs or facility videos—adds due diligence value.

What Are the Leading Hook and Loop Tape Manufacturers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Kai Rui Te Technology Company Ltd. | Shenzhen, CN | Hook & Loop Tapes (34); Webbing (36) | 100% | ≤1h | 36% | US $10,000+ | $0.04–$0.25 | 2 meters/100 pcs |

| Foshan CCH Textile Co., Ltd. | Foshan, CN | Hook & Loop Tapes (188); Cable Ties (11) | 100% | ≤7h | 23% | US $150,000+ | $0.08–$0.52 | 100–250 meters |

| Shenzhen Likou Textile Co., Ltd. | Shenzhen, CN | Hook & Loop Tapes; Back-to-Back Configurations | 100% | ≤2h | <15% | US $10,000+ | $0.06–$0.35 | 1,000 meters |

| Shenzhen Yuxinda Textile Co., Ltd. | Shenzhen, CN | Hook & Loop Tapes (290); Strong Adhesive Types | 58% | ≤2h | 17% | US $9,000+ | $0.04–$0.17 | 2–1,000 meters |

| Dongguan Baohui Textile Technology Co., Ltd. | Dongguan, CN | Webbing (81); Hook & Loop Tapes (30) | 72% | ≤5h | 16% | US $10,000+ | $0.06–$0.50 | 100–500 meters |

Performance Analysis

Shenzhen Kai Rui Te stands out for responsiveness (≤1h) and repeat business (36% reorder rate), indicating strong buyer confidence despite moderate listing volume. Foshan CCH demonstrates scale with high online revenue (US $150,000+) and extensive product variation, suggesting robust export activity and process maturity. Shenzhen Likou and Yuxinda offer competitive pricing but diverge in reliability—Likou achieves perfect on-time delivery at 1,000-meter MOQs, while Yuxinda’s 58% fulfillment rate presents a risk for time-sensitive contracts. Dongguan Baohui, though diversified, shows slower response patterns, potentially affecting project coordination.

FAQs

How to verify hook and loop tape manufacturer reliability?

Evaluate performance metrics such as on-time delivery rate, reorder frequency, and communication speed. Request material datasheets and, where possible, conduct third-party lab tests for adhesion strength and durability. Video audits of slitting and packaging lines provide insight into operational rigor.

What is the typical lead time for custom hook and loop tape?

Standard orders ship in 10–15 days. Custom colors, widths, or adhesive formulations add 5–10 days. Tooling for specialty hook profiles may extend timelines to 25 days. Air shipping reduces delivery to 5–7 days globally.

Can manufacturers produce eco-friendly or sustainable hook and loop tape?

Yes. Several suppliers offer tapes made from recycled nylon or bio-based polymers. Look for claims of "eco-friendly" materials and request documentation on recyclability or compostability. Some producers use water-based adhesives to reduce VOC emissions.

Do suppliers provide free samples?

Many offer small-volume samples (2–5 meters) at no cost, especially if followed by a purchase commitment. Fully free samples are more likely from suppliers with high response efficiency and established reorder performance.

What are common customization options available?

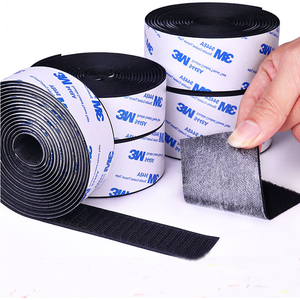

Options include width (10–100mm), length per roll, adhesive type (permanent/repositionable), liner presence, and attachment method (sew-on, self-adhesive). Die-cut shapes, printed logos, and multi-layer laminates are feasible with higher MOQs. Back-to-back configurations for cable management are widely available.