Hook And Loop Wholesaler

1/17

1/17

1/14

1/14

1/10

1/10

1/16

1/16

1/25

1/25

1/22

1/22

1/31

1/31

1/32

1/32

1/21

1/21

1/27

1/27

1/32

1/32

1/25

1/25

About hook and loop wholesaler

Where to Find Hook and Loop Wholesaler Suppliers?

China remains the central hub for hook and loop fastener manufacturing, with key production clusters in Zhejiang, Guangdong, and Yiwu. These regions host vertically integrated textile and polymer processing facilities that enable cost-efficient mass production. Ningbo and Shenzhen are particularly notable for their concentration of specialized suppliers combining weaving, coating, slitting, and adhesive application capabilities under one roof. This integration reduces component lead times by up to 40% compared to fragmented supply chains.

The industrial ecosystems support both commodity-grade and engineered fasteners, with access to raw materials such as nylon 6, polyester, and thermoplastic polyurethane (TPU) backing. Localized material sourcing cuts input costs by 15–25% relative to non-Asian producers. Suppliers in these zones typically operate automated production lines capable of achieving monthly outputs exceeding 500,000 meters, accommodating bulk orders while maintaining turnaround times of 15–25 days for standard configurations.

How to Choose Hook and Loop Wholesaler Suppliers?

Procurement decisions should be guided by systematic evaluation of supplier capabilities:

Material & Process Compliance

Confirm adherence to international standards such as RoHS and REACH for chemical safety, especially for consumer-facing applications. For medical or automotive uses, demand test reports on peel strength (measured in N/cm), shear resistance, and cycle durability (typically 1,000–10,000 closures). Verify use of UV-stable dyes for outdoor-rated products.

Production Capacity Verification

Assess operational scale through measurable indicators:

- Minimum factory area of 2,000m² indicating dedicated production space

- In-house coating and laminating lines enabling adhesive customization

- Slitting and die-cutting equipment for precise width and shape control

Cross-reference declared capacities with on-time delivery performance—suppliers maintaining ≥97% fulfillment rates demonstrate reliable workflow management.

Customization and Transaction Security

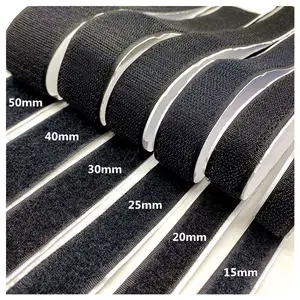

Prioritize partners offering documented customization options including color matching (Pantone or RAL), variable widths (10–100mm), pile density adjustments, and self-adhesive backing types (acrylic or rubber-based). Ensure packaging and labeling can be tailored for private-label distribution. Utilize transaction platforms with verified payment escrow and dispute resolution mechanisms to mitigate counterparty risk.

What Are the Best Hook and Loop Wholesaler Suppliers?

| Company Name | Verified Supplier Type | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Min. Order Flexibility | Customization Options |

|---|---|---|---|---|---|---|---|

| Ningbo Sunshine Import & Export Co., Ltd. | Custom Manufacturer | US $50,000+ | 76% | 27% | ≤6h | 10 cartons | Color, material, size, logo, packaging, label, graphic |

| Yiwu Hb Trading Co., Ltd. | Multispecialty Supplier | US $850,000+ | 100% | 21% | ≤4h | 2 rolls | Color, material, size, logo, packaging, label, graphic |

| Dongguan Jia En Technology Co., Ltd. | Multispecialty Supplier | US $650,000+ | 97% | 16% | ≤1h | 10 pieces | Color, material, size, logo, packaging, label, graphic |

| Shenzhen Xiechang Textile Products Co., Ltd. | Custom Manufacturer | US $40,000+ | 100% | 45% | ≤1h | 2 meters | Color, material, size, logo, packaging, label, graphic |

| Shenzhen Dongsanxin Textile Co., Ltd. | Multispecialty Supplier | US $30,000+ | 100% | 17% | ≤3h | 1000 meters | Color, material, size, logo, packaging, label, graphic |

Performance Analysis

Suppliers like Yiwu HB Trading and Shenzhen Xiechang demonstrate exceptional responsiveness and order reliability, with 100% on-time delivery and sub-4-hour average response times. Shenzhen Xiechang stands out with a 45% reorder rate, indicating strong customer satisfaction despite lower revenue volume. Dongguan Jia En offers the lowest MOQs (as low as 10 pieces), making it ideal for prototyping or niche market testing. Ningbo Sunshine, while exhibiting slightly lower delivery performance, operates as a custom manufacturer with full design-to-production capabilities. Buyers seeking high-volume consistency should prioritize suppliers with proven adhesive lamination control and reel-to-reel quality inspection systems.

FAQs

How to verify hook and loop wholesaler reliability?

Validate compliance with material safety regulations through third-party lab reports. Request video audits of production lines to confirm in-house processing capabilities. Analyze historical transaction data focusing on delivery consistency and post-purchase communication.

What is the typical sampling timeline?

Standard samples are produced within 7–14 days. Custom formulations (e.g., flame-retardant or conductive variants) may require 18–25 days. Air shipping adds 5–10 business days for international delivery.

Can suppliers accommodate small batch orders?

Yes, several suppliers accept MOQs as low as 10 pieces or 2 meters. However, unit costs decrease significantly at volumes exceeding 1,000 meters or 5,000 units, where economies of scale apply.

Do manufacturers offer free samples?

Sample policies vary. Many suppliers provide chargeable samples refundable against future orders. Expect sample fees ranging from $20–$50, covering material and handling costs.

How to initiate customization requests?

Submit detailed specifications including required tensile strength, substrate type (fabric, foam, plastic), adhesive tack level, temperature resistance, and desired roll lengths. Reputable suppliers will respond with technical feasibility assessments and prototype timelines within 48 hours.