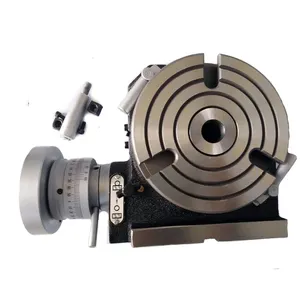

Horizontal Cnc Rotary Table

Top sponsor listing

Top sponsor listing

1/8

1/8

1/23

1/23

1/8

1/8

1/25

1/25

1/4

1/4

About horizontal cnc rotary table

Where to Find Horizontal CNC Rotary Table Suppliers?

China remains the central hub for precision motion control components, with key manufacturing clusters in Jiangsu, Guangdong, and Shandong provinces driving innovation and cost efficiency in horizontal CNC rotary table production. Wuxi and Shanghai-based suppliers leverage advanced machining infrastructure and proximity to semiconductor and automation industries, enabling tight integration of servo systems and high-precision indexing mechanisms. Dongguan and Shenzhen manufacturers specialize in compact, modular designs suited for multi-axis CNC integration, benefiting from regional expertise in electronics and mechatronics.

These industrial ecosystems support vertically integrated production—from raw material sourcing to final assembly—reducing component lead times by up to 40% compared to decentralized supply chains. Suppliers within these zones typically operate under ISO-aligned quality management frameworks and maintain access to certified heat-treated alloy steels and hardened bearing races essential for long-term repeatability. Buyers benefit from localized technical talent pools, with engineering teams often comprising 10–15% of workforce totals, supporting rapid prototyping and customization cycles averaging 15–25 days for non-standard configurations.

How to Choose Horizontal CNC Rotary Table Suppliers?

Evaluate potential partners using the following criteria to ensure technical compatibility and supply chain reliability:

Technical Compliance & Quality Assurance

Confirm adherence to international dimensional and performance standards such as ISO 230-2 (positioning accuracy) and ISO 10791-7 (indexing precision). For export markets, CE marking indicates compliance with EU machinery directives, particularly relevant for automated or servo-driven models. Request test reports verifying angular repeatability (typically ±5 to ±15 arc seconds), backlash tolerance, and load capacity under dynamic conditions.

Production Capability Assessment

Assess operational scale and technical depth through verifiable metrics:

- Facilities equipped with CNC grinding, gear hobbing, and hard-turning capabilities to ensure tooth profile accuracy in worm gear drives

- In-house motor integration (servo/hydraulic) and encoder calibration processes

- Demonstrated reorder rates above 30% indicate customer retention and product reliability

- On-time delivery performance exceeding 95% reflects robust production planning

Cross-reference supplier claims with response time data—those achieving ≤7 hours demonstrate dedicated sales-engineering coordination critical for technical inquiries.

Customization and Transaction Security

Leading suppliers offer configurable options including motor type, mounting interfaces, feedback systems (absolute/incremental encoders), and lubrication methods. Verify packaging protocols and labeling compliance for international shipments. Utilize secure transaction mechanisms where payment release is tied to inspection milestones. Prioritize suppliers providing detailed dimension drawings, 3D models, and functional specifications prior to order confirmation.

What Are the Best Horizontal CNC Rotary Table Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Product Range |

|---|---|---|---|---|---|---|---|

| Wuxi Fagor Technology Company Limited | Other Machine Tools Accessories, Machining Services, Tool Holder | US $110,000+ | 100% | 16% | ≤3h | Motor, color, disc, magazine, size, drawing, logo, packaging, label, graphic | 15 models listed |

| Shanghai Think Big Machine Tool Co., Ltd. | Other Machine Tools Accessories, Machining Services | US $40,000+ | 100% | 33% | ≤7h | Hydraulic station, motor, servo driver, core structure, dimensions, zero points, limits, material, logo, packaging | 5 models listed |

| Dongguan Jiezhun Precision Technology Co., Ltd. | Dividing Head, Machining Services, Table | Not specified | Not available | <15% | ≤5h | Limited public data | 5 models listed |

| Shandong Taiger Cnc Machine Tool Accessories Co., Ltd. | Dividing Head, Table, Generic Fitting | Not specified | 100% | Not available | ≤18h | Basic structural variants | 5 models listed |

| Shenzhen Dijin Machine Equipment Co., Ltd. | Chuck, Manual Lathe Vise, Drilling Machines | US $200,000+ | 95% | <15% | ≤7h | Mounting configurations, jaw types | 5 models listed |

Performance Analysis

Wuxi Fagor stands out for its extensive product range and rapid response capability (≤3h), making it suitable for buyers requiring frequent technical engagement. Shanghai Think Big demonstrates strong customer retention with a 33% reorder rate, indicating consistent satisfaction with build quality and customization execution. Shenzhen Dijin reports the highest online revenue (US $200,000+), suggesting broad market reach despite lower reorder metrics. While Shandong Taiger offers competitive entry-level pricing starting at $95, longer response times (≤18h) may delay project timelines. Dongguan Jiezhun provides high-torque roller-cam designs but lacks verified delivery performance data, presenting a higher risk for time-sensitive procurement.

FAQs

What materials are commonly used in horizontal CNC rotary tables?

Primary structures are cast from high-rigidity FC300/FC600 grade cast iron with stress-relieved treatment. Critical rotating components such as worm gears and shafts use SCM415 or 20CrMo alloy steel, carburized and ground to achieve surface hardness of HRC58–62 for wear resistance.

What is the typical lead time for standard and custom units?

Standard models ship within 15–30 days after order confirmation. Customized units requiring modified housings, special motors, or unique indexing patterns require 25–45 days, depending on complexity and component availability.

Do suppliers support OEM/ODM services?

Yes, most suppliers listed offer OEM branding, including logo engraving, custom paint colors, and tailored documentation. ODM support includes modifications to flange dimensions, interface protocols (e.g., BiSS-C, EnDat), and dual-position clamping systems.

What are common MOQ and pricing ranges?

Minimum order quantities are typically 1 piece/set. Entry-level manual rotary tables start at $95, while servo-driven, high-precision models (±5 arc sec) range from $1,000 to $9,500. Volume discounts apply at 5+ units, with negotiated reductions of 5–15%.

How to validate supplier credibility before ordering?

Request factory audit reports, ISO certification copies, and sample test records for runout, repeatability, and load testing. Conduct video inspections of machining centers and assembly lines. Use milestone-based payments linked to production phases and pre-shipment inspections.