How To Get Your Own Product Made

About how to get your own product made

Where to Find Custom Product Manufacturing Suppliers?

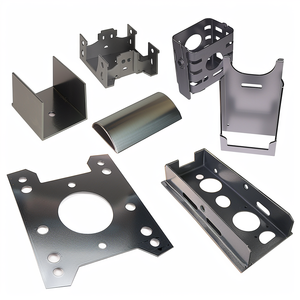

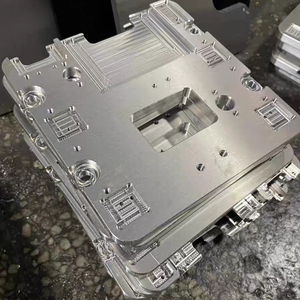

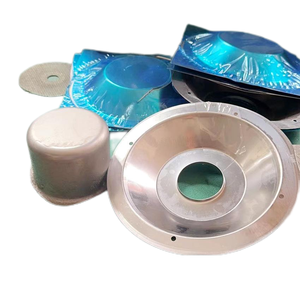

China remains the global hub for custom product manufacturing, with specialized industrial clusters in Guangdong, Zhejiang, and Hebei provinces offering distinct technical and logistical advantages. Shenzhen (Guangdong) is a leading center for electronics and precision components, supported by mature PCB design ecosystems and rapid prototyping infrastructure. Zhejiang excels in 3D printing and injection molding services, while Hebei has emerged as a key region for sheet metal fabrication and CNC machining, leveraging proximity to Tangshan’s steel production base to reduce material costs.

These regional specializations enable buyers to source highly technical, low-volume, or fully customized products efficiently. Vertically integrated supply chains allow for fast iteration cycles—critical for startups and SMEs developing new products. Typical lead times range from 7–15 days for prototypes and 20–35 days for bulk production, depending on complexity. Suppliers commonly support MOQs as low as 1 piece, particularly in prototyping and niche fabrication sectors, enhancing flexibility for early-stage product development.

How to Choose Custom Product Manufacturing Suppliers?

Selecting reliable partners requires structured evaluation across three core areas:

Technical Capabilities & Customization Scope

Confirm that suppliers offer required processing methods such as laser cutting, CNC machining, 3D printing, die casting, or PCB assembly. Evaluate their ability to handle customization based on drawings, samples, or functional specifications. Key indicators include support for material, color, size, logo, packaging, and graphic modifications. For electronic components, verify capabilities in firmware development, PCB cloning, and Gerber file processing.

Production Infrastructure and Quality Assurance

Assess operational scale and process control through verifiable metrics:

- Facilities equipped with in-house tooling, R&D teams, and dedicated quality inspection lines

- On-time delivery rates exceeding 90% and response times under 4 hours

- Evidence of standardized quality management systems (e.g., ISO 9001), though formal certification may not always be listed

Cross-reference supplier claims with transaction data such as reorder rates and online revenue volume, which reflect market validation and customer satisfaction.

Procurement Risk Mitigation

Implement safeguards to protect intellectual property and ensure product conformity:

- Use secure communication channels and request NDAs before sharing design files

- Require sample production before full-order commitment

- Structure payments with milestone-based disbursements tied to deliverables

- Verify export experience and logistics coordination capacity, especially for air or sea freight compliance

What Are the Best Custom Product Manufacturing Suppliers?

| Company Name | Location | Main Products | Customization Support | MOQ Range | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|---|

| Hangzhou Great Wave Industrial Technology Ltd | Zhejiang, CN | Aluminum alloy parts, die-casting, sheet metal | Drawing-based, sample, light customization | 1–500 pcs | $0.50–$11.35 | 93% | ≤5h | 39% | US $700,000+ |

| Shenzhen UC Industrail Limited | Guangdong, CN | PCB design, SMD boards, automotive electronics | Gerber files, reverse engineering, firmware | 1 pc | $0.50–$10 | 100% | ≤4h | 47% | US $160,000+ |

| Zhejiang Yunjiang High Tech Co., Ltd. | Zhejiang, CN | 3D printed goods, vases, metal printing | OEM/ODM, material, logo, packaging | 1 pc | $0.39–$6.95 | 100% | ≤2h | 46% | US $60,000+ |

| Shenzhen Omk Electronics Co., Ltd. | Guangdong, CN | Laser cutting, welding, aluminum/copper parts | Flexible, drawing-based, on-demand | 1 pc | $0.79–$200 | 88% | ≤2h | 22% | US $40,000+ |

| Hebei Nanfeng Metal Products Co., Ltd. | Hebei, CN | Sheet metal, table frames, brackets | Drawing-based, modern metal fittings | 10–100 pcs | $0.20–$6.80 | 100% | ≤4h | <15% | US $20,000+ |

Performance Analysis

Hangzhou Great Wave stands out for high-volume capability and strong market traction (US $700K+ revenue), making it suitable for scaling production. Shenzhen UC Industrial and Zhejiang Yunjiang achieve 100% on-time delivery with robust customization options, ideal for electronics and additive manufacturing projects. Hebei Nanfeng offers competitive pricing for sheet metal work but has a lower reorder rate, suggesting potential gaps in post-sale service. Shenzhen-based suppliers lead in responsiveness and technical agility, particularly for low-MOQ, prototype-driven orders.

FAQs

How to verify a custom manufacturing supplier's reliability?

Review on-time delivery performance, reorder rates, and response times as behavioral indicators of reliability. Request facility photos or video tours to confirm in-house production. Validate technical claims by testing samples against functional or dimensional specifications.

What is the typical sampling timeline for custom products?

Sample production generally takes 5–10 days for mechanical parts and 7–14 days for electronic assemblies. Additive manufacturing or complex metal fabrication may require up to 18 days. Air shipping adds 5–7 days for international delivery.

Can suppliers handle small batch or single-unit production?

Yes, many suppliers support MOQs of 1 piece, especially in prototyping, 3D printing, and PCB manufacturing. Sheet metal and die-casting services typically require minimum batches of 10–500 units due to setup costs.

Do manufacturers provide free samples?

Free samples are uncommon for custom work. Most suppliers charge full or partial cost for initial prototypes. Fees may be waived upon confirmation of large-volume orders.

How to initiate a custom product manufacturing project?

Begin by submitting detailed technical drawings, material specifications, or physical samples. Clearly define requirements for dimensions, tolerances, surface finish, and packaging. Reputable suppliers will respond with feasibility assessments, quotations, and estimated timelines within 24–48 hours.