Html Tags

1/18

1/18

1/1

1/1

1/11

1/11

1/3

1/3

1/15

1/15

0

0

1/6

1/6

1/2

1/2

0

0

1/20

1/20

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

1/24

1/24

1/21

1/21

1/3

1/3

0

0

About html tags

Where to Find HTML Tags Suppliers?

The global supply base for custom garment hang tags—commonly referred to as "HTML tags" in sourcing contexts—is heavily concentrated in China’s Pearl River Delta region, particularly within Guangdong and Fujian provinces. This industrial cluster hosts a dense network of printing, packaging, and textile accessory manufacturers that benefit from vertically integrated production ecosystems. Proximity to raw material suppliers (e.g., coated paper, cotton strings, PVC films) and downstream apparel factories enables rapid prototyping and cost-efficient batch production.

Suppliers in this region operate within mature logistics corridors, allowing for streamlined export operations via Shenzhen and Guangzhou ports. The concentration of specialized subcontractors—ranging from die-cutting studios to UV varnishing units—supports high levels of customization at competitive unit prices. Economies of scale reduce per-unit costs by up to 30% compared to Western-based producers, while average lead times range from 7–15 days for sample batches and 20–30 days for mass orders.

How to Choose HTML Tags Suppliers?

Selecting reliable suppliers requires rigorous evaluation across three core dimensions:

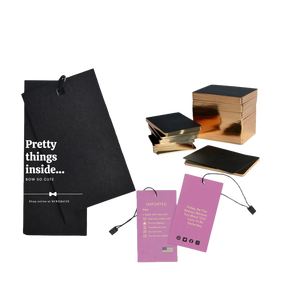

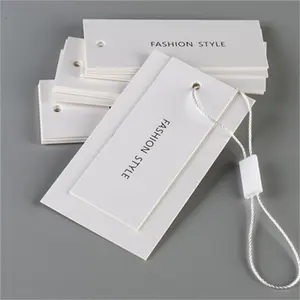

Production & Customization Capability

Assess the breadth of available materials and finishing techniques. Leading suppliers offer multiple substrate options including recycled kraft paper, black cardstock, cotton fabric, and transparent PVC. Key processing capabilities should include foil stamping, embossing/debossing, UV coating, and die-cut shaping. Confirm access to digital mockup tools for pre-production design validation.

Order Flexibility and Scalability

Evaluate minimum order quantity (MOQ) thresholds and pricing tiers. As observed in current market data, MOQs vary significantly—from 50 pieces for premium small-batch runs to 1,000+ units for economy-scale production. Unit prices typically range between $0.01 and $0.60 depending on material complexity and finishing requirements. Prioritize suppliers offering tiered pricing structures aligned with your volume needs.

Operational Reliability Metrics

Use performance indicators to filter candidates:

- On-time delivery rate ≥97%

- Average response time ≤2 hours

- Reorder rate >20% indicating customer retention

- Evidence of sustained online transaction volume (e.g., annual revenue exceeding US $100,000)

Cross-reference these metrics with product listing diversity—suppliers specializing in garment tags, labels, and packaging accessories tend to demonstrate deeper domain expertise than generalists.

What Are the Best HTML Tags Suppliers?

| Company Name | Primary Products | Customization Options | Min. Order Quantity | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Annual Revenue (Est.) |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Fanxi Pudding Network Co., Ltd. | Garment Tags, Packaging Labels, Paper Boxes | Foil stamping, embossing, UV varnish, debossing, die-cut shapes, color string options | 100–1,000 pcs | $0.01–$0.10 | 95% | ≤2h | 25% | US $240,000+ |

| Dongguan Douyang Packaging Products Co., Ltd. | Garment Tags, Patches, Packaging Labels | Limited to standard finishes; focus on bulk paper tags | 500–1,000 pcs | $0.01–$0.09 | 97% | ≤3h | 23% | US $30,000+ |

| Shishi Hengbo Hardware Factory (Individual Business) | Garment Tags, Patches, Labels | 3D relief printing, eco-friendly UV inks, canvas/PVC variants | 50 pcs | $0.08–$0.09 | 100% | ≤1h | 18% | US $120,000+ |

| Guangzhou Langyin Network Technology Co., Ltd. | Hang Tags, Recyclable Paper Labels, PVC Tags | Color, thickness, rope type, logo debossing, graphic design support | 100 pcs | $0.01–$0.15 | 99% | ≤2h | 23% | US $130,000+ |

| Guangzhou Liangdian Printing & Packaging Co., Ltd. | Luxury Hangtags, Plastic Bags, Garment Labels | Foil stamping, luxury finishes, custom shapes, safety pin integration | 2–100 pcs | $0.30–$0.60 | 100% | ≤2h | <15% | US $70,000+ |

Performance Analysis

Guangzhou Fanxi Pudding Network stands out for its extensive customization portfolio and strong reorder rate (25%), supported by robust transaction volume. Dongguan Douyang offers competitive pricing for large-volume buyers but has a higher MOQ threshold and lower responsiveness. Shishi Hengbo excels in operational efficiency with a 100% on-time delivery rate and sub-one-hour response time, making it ideal for urgent or agile sourcing cycles despite a moderate reorder rate.

Guangzhou Langyin provides broad material flexibility and mid-range pricing, suitable for brands balancing sustainability (recyclable paper) with branding impact. Guangzhou Liangdian targets premium segments with high-end designs and ultra-low MOQs (as low as 2 pieces), though its lower reorder rate suggests potential gaps in long-term client satisfaction. Buyers seeking luxury positioning may leverage this supplier for sampling and limited editions.

FAQs

How to verify HTML tags supplier reliability?

Analyze verified performance metrics such as on-time delivery rate, response speed, and historical transaction volume. Request digital proof files and physical samples to evaluate print accuracy, material quality, and finishing precision before placing bulk orders.

What is the typical lead time for custom hang tags?

Sample production takes 5–10 days, with express options available in 3–5 days. Mass production lead times range from 15–25 days depending on order size and process complexity. Add 5–10 days for international air freight or 20–40 days for sea shipping.

Can suppliers accommodate eco-friendly materials?

Yes, multiple suppliers offer recyclable kraft paper, biodegradable strings, and water-based or UV-cured inks. Confirm material certifications upon request, especially for EU or North American markets requiring compliance with environmental labeling standards.

Do suppliers provide free design support?

Most suppliers include basic layout and mockup services at no additional cost. Advanced graphic design or 3D rendering may incur fees unless bundled with large-volume contracts.

How to negotiate better pricing on hang tags?

Leverage volume commitments, consolidate SKUs into single production runs, and opt for standardized materials and sizes. Suppliers often reduce unit costs by 15–25% when transitioning from small-batch to mid-volume tiers (e.g., 1,000+ units).