I2c Protocol

1/3

1/3

1/3

1/3

1/55

1/55

1/1

1/1

1/11

1/11

1/11

1/11

1/25

1/25

1/3

1/3

0

0

1/6

1/6

1/3

1/3

0

0

1/3

1/3

1/1

1/1

1/3

1/3

1/1

1/1

1/3

1/3

0

0

1/3

1/3

1/3

1/3

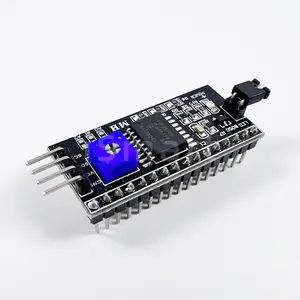

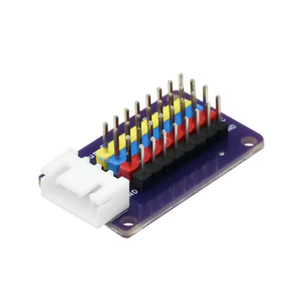

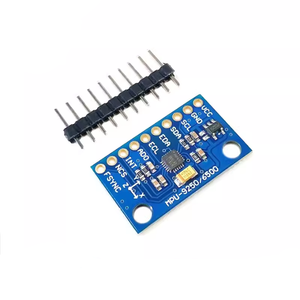

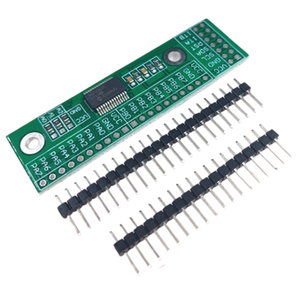

About i2c protocol

Where to Find I2C Protocol Suppliers?

No active suppliers specializing in I2C protocol-related components were identified in the current dataset. The I2C (Inter-Integrated Circuit) protocol, a widely adopted serial communication standard for low-speed peripheral interfacing in embedded systems, is typically integrated into semiconductor devices, sensor modules, and microcontroller units rather than offered as a standalone product. As such, sourcing efforts are generally directed toward electronics manufacturers, PCB integrators, or IC design houses capable of implementing I2C functionality within broader system architectures.

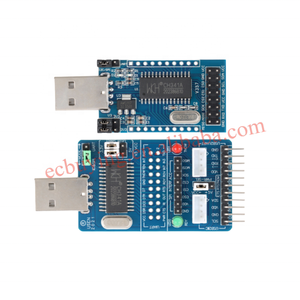

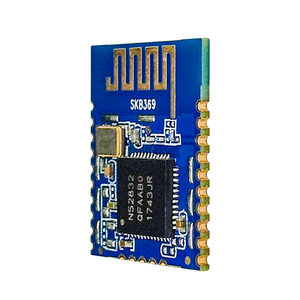

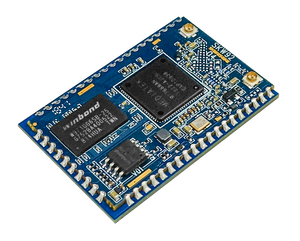

In global electronics manufacturing hubs—particularly in Guangdong, Jiangsu, and Zhejiang provinces in China—thousands of OEMs and ODMs offer I2C-enabled solutions across consumer electronics, industrial automation, and IoT applications. These regions benefit from mature supply chains for semiconductor packaging, surface-mount technology (SMT), and firmware programming, enabling cost-efficient integration of I2C interfaces. Buyers seeking custom I2C implementations should target facilities with SMT lines, embedded software development capabilities, and experience in bus protocol configuration.

How to Choose I2C Protocol Suppliers?

Selecting qualified partners requires rigorous technical and operational assessment:

Technical Compliance

Confirm adherence to relevant standards including NXP’s I2C-bus specification (UM10204) and compatibility with standard modes (100 kbit/s), fast mode (400 kbit/s), and high-speed variants (3.4 Mbit/s). For regulated industries, verify compliance with RoHS, REACH, and ISO 9001 quality management systems. Request schematics, pull-up resistor configurations, and address mapping documentation to ensure interoperability.

Production Capability Audits

Evaluate supplier infrastructure for electronic assembly and testing:

- Minimum 2,000m² cleanroom or ESD-protected facility for PCB assembly

- In-house SMT lines with placement accuracy supporting QFN, TSSOP, and BGA packages

- Firmware loading and I2C bus validation stations using logic analyzers or oscilloscopes

Cross-reference production logs with functional test yields (target >95%) and bus error rates under load conditions.

Transaction Safeguards

Utilize escrow-based payment terms until prototype validation is completed. Review supplier track records via verified transaction histories and technical support responsiveness. Pre-production sampling is critical—test I2C signal integrity, clock stretching behavior, and multi-master arbitration before volume orders.

What Are the Best I2C Protocol Suppliers?

At this time, no suppliers are listed in the available data offering dedicated I2C protocol services or components. The absence of identifiable vendors suggests that procurement strategies should focus on integrated electronics manufacturers capable of embedding I2C communication layers within application-specific hardware designs. Buyers are advised to engage firms with demonstrated experience in embedded communications protocols, particularly those providing full turnkey solutions including schematic design, PCB layout, device driver development, and I2C slave addressing schemes.

Performance Analysis

Without active supplier entries, performance benchmarking cannot be conducted. However, industry best practices indicate that leading electronics manufacturers in East Asia achieve lead times of 20–35 days for small-batch I2C-enabled module production, with MOQs ranging from 100 to 1,000 units depending on component availability and customization depth. Prioritize suppliers with documented I2C debugging workflows, SPICE simulation capabilities, and experience resolving common issues such as bus contention, ground loops, and rise time violations.

FAQs

How to verify I2C protocol supplier reliability?

Audit technical documentation including bill of materials (BOM), gerber files, and I2C initialization code. Validate firmware source control practices and demand test reports showing successful communication across multiple slave devices. Confirm use of standard 7-bit or 10-bit addressing and support for required operating voltages (e.g., 3.3V or 5V logic levels).

What is the average sampling timeline?

Prototype development for I2C-integrated circuits typically takes 15–30 days, depending on component lead times and firmware development complexity. Add 5–10 days for international express shipping. Complex multi-node I2C networks may require additional validation cycles.

Can suppliers ship I2C-enabled products worldwide?

Yes, qualified electronics manufacturers support global distribution. Confirm compliance with destination market regulations, including FCC, CE, or KC marks where applicable. Use FOB or DDP shipping terms based on risk tolerance and import clearance capabilities.

Do manufacturers provide free samples?

Sample policies vary by complexity. Basic I2C sensor modules may be provided at no cost for qualified buyers committing to medium-volume production. Custom designs typically require full cost recovery for NRE (non-recurring engineering) expenses, including PCB fabrication and firmware adaptation.

How to initiate customization requests?

Submit detailed requirements including target bus speed, master/slave configuration, voltage levels, connector types, and environmental specifications (temperature, humidity). Reputable suppliers will respond with circuit proposals, timing diagrams, and estimated development timelines within 5–7 business days.